The Top 10 in Trenchless Engineering for 2018

Leading Design Firms Apply Innovative Trenchless Solutions to Big Projects in 2018

As noted in the analysis of Trenchless Technology’s 2018 Top 50 Trenchless Engineering Firms survey, this year’ top 50 reported a collective $1.42 billion-plus in trenchless revenue. Of that, more than $1.02 billion came from the top 10 in the ranking. In just the past year, the top 10 completed thousands of projects that involved trenchless design. Here are some summaries of recent projects sent our way from this year’s top 10.

RELATED: Top 50 Trenchless Engineering Firms of 2018: Trenchless, by Design

Jacobs

Jacobs

Water Rehabilitation for Emergency and Potable Supply in West Potomac Park

The existing water conveyance system located within the National Mall in Washington, D.C., serves the Washington Monument, Lincoln Memorial, WWII Memorial and the Vietnam War Memorial. The project included the replacement of 12,000 lf of water mains and 3,000 ft of services installed between 1908 and 1942 by the War Department.

Horizontal directional drilling was the preferred trenchless installation method to install new HDPE pipe. The project required minimization of the construction footprint given the year-round high pedestrian activity in the area. Subsurface conditions encountered were fill (fat clays and silts) to sands and gravels overlying low shear strength alluvial deposits. The horizontal alignment followed the existing system however the vertical alignment was between 8 to 12 ft below the ground surface avoid existing utilities and to remain above the weak alluvial deposits.

Unexpected challenges encountered included historic buried foundations for WWII barracks, working in close proximity to the curious public and creatively managing shallow cover to reduce the potential for inadvertent returns (hydro fracture).

In its efforts to alleviate CSOs in its territory, NYCDEP planned the Bergen Basin project with lead consultant Hazen & Sawyer and underground facilities designer and geotechnical consultant Mott MacDonald.

Mott MacDonald

Bergen Basin Sewer Reconstruction in Queens

The wastewater collection system for the neighborhood of South Ozone Park in Queens passes beneath the heavily traveled Belt Parkway before reaching the Jamaica Water Pollution Control Plant at the western end of JFK International Airport. When the sewer reaches capacity, combined sewer overflows cause untreated wastewater to reach the narrow inlet of Bergen Basin. From there, it flows into Jamaica Bay, the site of important habitat and a wildlife refuge.

RELATED: Innovative Solutions Help Complete Tricky Microtunneling Project Under Belt Parkway

Mott MacDonald provided trenchless and tunneling expertise for the construction of a new interceptor sewer under the Belt Parkway. The alignment passed through artificial fill and glacial outwash, beneath a sewer with only inches of clearance, beneath water mains, and below a high-pressure gas main. Probe holes were drilled using horizontal directional drilling to provide greater certainty that there would be no impenetrable obstacles to the drives beneath the Belt Parkway. The project was completed successfully, at a cost less than the original estimates. By eliminating a wastewater bottleneck, combined sewer overflows will be significantly reduced and the water quality of Bergen Basin and Jamaica Bay improved.

Stantec

South Surrey Interceptor Johnston Road Section – Phase 2

The South Surrey Interceptor Johnston Road Section – Phase 2 project consists of an approximately 800 m (2,624 ft) long, 3,050-mm (10-ft) diameter gravity sewer in Surrey, British Columbia. Currently under construction, the interceptor will collect sewage from South Surrey, White Rock and Langley and convey it to the Annacis Island Wastewater Treatment Plant. The contractor elected to use a 3.6-m (11.8-ft) outer diameter microtunnel boring machine to install the reinforced concrete pipe using two straight drives and two drives with horizontal curves.

This is believed to be the largest microtunnel project (by diameter) ever completed in North America. The longest drive will be approximately 355 m (1,164 ft). Key project challenges include tunneling beneath business parks and city streets, bouldery ground, and tunneling near several utilities. Stantec’s responsibilities included performing the geotechnical investigation, preliminary and detailed design, and contract administration and inspection during construction.

A sewer force main was successfully installed under Victoria Harbour in British Columbia, including a pipe pullback through a quiet residential neighborhood, thanks to detailed planning and collaboration between the contractor (Michels Canada) and the engineering team (AECOM), as well as implementation of a proactive public relations campaign.

AECOM

Capital Regional District Wastewater Treatment

As part of a joint venture, AECOM is providing a new state-of-the-art wastewater treatment plant (WWTP) on a point of land across the harbor from Victoria, British Columbia under a design-build contract for the Capital Regional District. As part of the project, a new pipeline had to be installed underneath the harbor to convey wastewater to the new plant.

Due to the length of more than 3,000 ft through very hard granitic rock, the joint venture decided the crossing was to be constructed by Horizontal Directional Drilling. The high anticipated stresses during pull back, required a 1-in. wall 42-in. diameter steel pipe to be specified. The pipe laydown area went through a quiet residential neighborhood in the City of Victoria, where community activities were organized including paintings by local schools on the pipeline.

RELATED: Improving the Marine Environment: HDD Under the Victoria Harbour

Corrosion protection was necessary since the pipe was to convey raw sewage. Exterior pipe coatings were also necessary where the pipe passed through potentially corrosive overburden soils. Drilling was completed in April 2018, three months ahead of schedule. The project was completed in June 2018 with the successful testing of hydrostatic pressure for leakage. The WWTP construction is currently under way and is scheduled to be completed in 2020.

Black & Veatch Corp.

City of Minneapolis Water Main Replacement

Faced with an aging 54-in. water main that is more than 70 years old, the City of Minneapolis contracted with Black & Veatch to perform a study, detailed design, and construction management services to replace the water main. The initial study concluded that replacing the existing water main with a new pipeline tunneled beneath the Mississippi River would be the best long-term alternative to balance both cost and water main maintenance.

The design included 920 lf of 48 in. water main under the Mississippi River using microtunneling. Shorter sections of open-cut construction methods are required to connect the new 48 in. water main to existing piping. The working shaft will be approximately 20 ft in diameter, and the retrieval shaft will be 10 ft in diameter. Both shafts will be constructed using water tight ground support systems to mitigate high groundwater inflows and prevent migration of a contaminated groundwater plume. The retrieval shaft will be 130 ft deep to accommodate the existing topography.

The project will also include the replacement of 48-in. piping installed vertically in an existing, 80-ft deep shaft constructed in 1917. The annular space in this shaft will be grouted once the new pipe is installed.

Hatch Corp.

Regional Municipality of Halton’s Mid-Halton Effluent Outfall

Construction of the Regional Municipality of Halton’s $80 million Mid-Halton Effluent Outfall was completed earlier in 2018. Hatch managed this project from the Environmental Assessment stage through preliminary design, detailed design and construction. The project was completed entirely by tunneling and included two 50-m deep shafts, 4.2 km of onshore tunneling beneath residential and commercial neighborhoods and 2.1 km of offshore tunneling beneath Lake Ontario. The tunnel was mined to 3.5m in diameter and lined to 2.6 m in diameter. Offshore, the tunnel intersected with 18 pre-drilled riser/diffuser assemblies. Onshore, the shaft at the wastewater treatment plant was finished as a baffle-drop structure and included a micro-turbine unit to generate electricity from the falling effluent.

CDM Smith

Providence Water Emergency Repair, Risk Assessment & Inspection

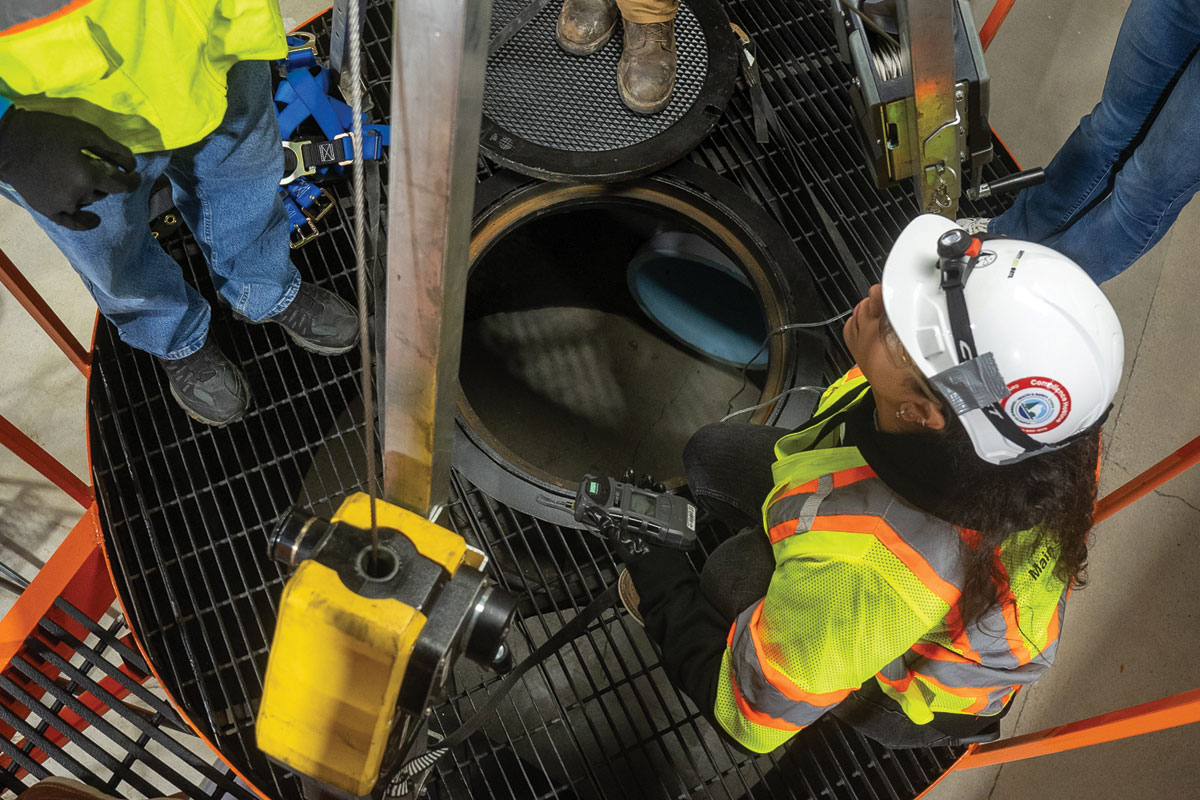

Providence Water (PW), Rhode Island’s largest water utility, has been relying on the expertise of CDM Smith professionals for its prestressed concrete cylinder pipe (PCCP) assessment and rehabilitation needs for more than 20 years. Following a catastrophic failure of its 102-in. prestressed concrete cylinder pipe (PCCP) aqueduct in 1996 that caused significant property damage and interrupted water supply to their wholesale customers, PW retained CDM Smith to perform emergency repair services and develop a comprehensive investigation program for PW, including a pipeline risk assessment and inspection program, which has facilitated systematic repairs to the 78-in. and 102-in. Supplemental Tunnel and Aqueduct (STA). CDM Smith has assisted PW with the implementation of the program.

Most recently in 2017, CDM Smith completed rehabilitation of approximately 1,285 lf of 78-in. PCCP via sliplining to restore the structural integrity of the aqueduct. Data collected from visual, structural sounding, and electromagnetic (EM) inspections, compared with previously developed failure risk curves and repair prioritization of distressed pipes, identified highly distressed 78-in. PCCP pipe in need of immediate repair. These pipe reaches were repaired with 69-in. diameter centrifugally cast, fiberglass reinforced, polymer mortar (CCFRPM) using a combination of sliplining and open-cut construction methods.

Cardno

Subsurface Utility Engineering – Phoenix South Central LRT Project

Cardno was selected as a Utility Engineer on the Valley Metro program management team for the South Central LRT project in Phoenix, Arizona, providing subsurface utility engineering services utilizing the ASCE 38-02 standards as well as survey/mapping services, as part of the team with HDR.

The Cardno field investigations team mapped more than 700,000 lf of subsurface utilities through two phases, effectively mapping 80 percent more utilities than were on utility record alone. The investigation discovered more than 125 unknown utilities stretching more than two miles of undocumented lines. These findings greatly reduced the risk of impacts on this project. The project included conducting records research (CI/ASCE 38-02 Quality Level D), field observations (Quality Level C), designating utilizing geophysical equipment to horizontally position the subsurface utilities (Quality Level B), subsurface structure reviews/diagrams, Utility Coordination, and full CAD drawings for the transit project.

In addition, the CMAR team lead originally requested more than 4,000 Quality Level A test holes based on project size. Once the utility mapping was complete, the design team was able to update and optimize the design using the high-quality mapping Cardno provided and reduced the number of holes by more than 2,800, saving approximately $2.5 million in reduced test hole, traffic control and pavement restoration fees.

A bridge was constructed across the Speed River to divert the Hespeler Trunk Sanitary Sewer during the rehabilitation process.

GHD

City of Cambridge Hespeler Trunk Sanitary Sewer Project

Working with the City of Cambridge, GHD rehabilitated the Hespeler Trunk Sanitary Sewer. The project consisted of the structural rehabilitation of 4,500 ft of large diameter sewer. GHD provided a full range of services from condition assessment to oversight and warranty. Some of the highlight include:

- The sewer system was improved to a Grade 1;

- The CIPP method reduced the schedule and capital expenditure;

- GHG carbon emissions calculator showed a reduction of 790 tons were eliminated;

- Achieved 8-10 percent reduction in infiltration; and

- The project was completed on-time and under budget and was awarded 2018 Project of the Year from the Centre for Advancement of Trenchless Technologies (CATT).

RELATED: Trenchless Insights: A Q&A with GHD’s Bradley Marin

KCI Technologies

SUE Mapping in Corpus Christi, Texas

The KCI team provided subsurface utility engineering, research and GIS coordination to map more than 570,000 lf of utilities in support of the design-build contract to replace the SH-181 Harbor Bridge in Corpus Christi, Texas. The $900 million project involves construction of a new cable-stayed crossing with a 1,661-ft-long main span and 6.5 miles of approach and connecting roadway. The congested corridor included miles of water, wastewater, oil and gas, electric, telecommunications and fiber optic infrastructure that required locating, engineering review and/or relocation design services. KCI’s incredible team provided Quality Levels A-D locating and excavation, development of a detailed conflict matrix, and subsequent utility coordination and relocation design required for this mega-project.

Andrew Farr is associate editor of Trenchless Technology.