How to Control the Hazards of Confined Space

The underground infrastructure industry has many safety risks and certainly one at the top of this list is confined space. According to data from the Bureau of Labor Statistics, over 1000 workers in the United States have died from injuries involving confined spaces, averaging around 130 deaths per year. This roughly translates to about two confined space fatalities per week, with the most common causes being hazardous atmosphere changes during entry.

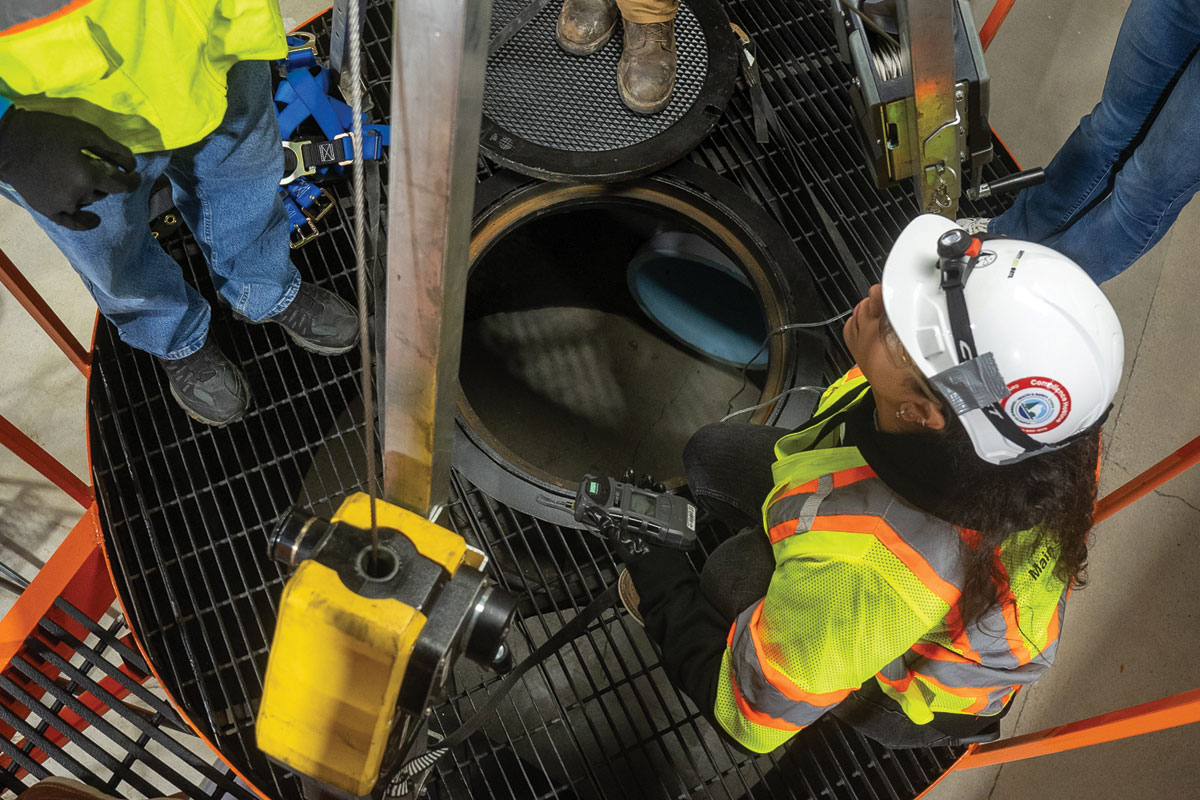

One way the industry can prevent these deaths, is understanding these hidden dangers and the critical importance of proper preparedness in confined space. This includes but is not limited to sewer structure rehabilitation, manhole entry, and infrastructure inspection processes. Any incidents or accidents during confined space entry are of particular concern to the health and safety of workers due to the hazards that they pose to the entrant as well as the attendant.

NASSCO has taken the lead in education and training programs to assist the industry with a better understanding of confined space hazards by providing a new video that breaks down the Occupational Safety and Health Administration (OSHA) standard as well as identifying critical components that companies should focus on when completing confined space tasks.

To begin, we need to understand the definition of confined space. According to OSHA, a permit-required confined space is generally recognized as a space that:

- Has limited or restricted means of entry or egress.

- Is large enough for a person to enter to perform work.

- Is not designed for continuous occupancy.

- Contains or has the potential to contain a hazardous atmosphere.

- Has the potential to engulf the entrant.

- Is designed in a manner that could cause an entrant to be trapped.

If you look at the guidelines and apply them to all sewer and culvert structure rehabilitation, these entries should be considered permit-required confined space entry due to the possibility of one or all the conditions above existing at any given time.

One of the primary tasks that should be completed prior to working in sewer structure access points is that each employer must have a written program. In developing such a program, there are a few critical items that an employer should consider, including evaluating confined spaces for hazards, identifying what your company will consider confined spaces and establishing policies to control the identified hazards as well as setting up confined space procedures for entering the space.

While not intended to replace proper confined space entry training, the NASSCO Confined Space video will walk you through some key elements of the standard that are designed to protect workers from unknown hazards and potential injury while working in confined spaces.

- Permits: Prior to entering the Confined Space, a Confined Space Permit must be filled out completely.

- Continuous Air Monitoring and Atmospheric Testing: Before an employee enters the space, the entire internal atmosphere shall be tested. In addition, when conducting air monitoring of a confined space be sure to test all levels of the confined space (top, middle and bottom). Typically, the sewer rehabilitation industry should include sensors for the following: Oxygen, LEL, Hydrogen Sulfide, and Carbon Monoxide.

- Continuous Ventilation: After the initial air sampling has occurred, start the ventilation process but always continue air monitoring.

- Properly Fitted Harness: When entering a confined space, the entrant must wear a harness for both retrieval and fall protection.

- Retrieval and Fall Protection: Entrants must be attached to a retrieval winch and fall protection device. When the entrant is being lowered into a sewer structure access point, the entrant must be attached to a Self- Retracting Lifeline (SRL) to prevent a fall in addition to the retrieval winch.

Lastly, the NASSCO video will cover the topic of confined space training. All confined space workers must be trained per the OSHA 1926 Construction Confined Space Standard. Employers must train workers involved in permit-required confined space operations so that they can perform their duties safely and understand the hazards in permitted spaces and the methods used to isolate, control, or protect workers.

While the OSHA standard provides information and tools needed for confined space, NASSCO has created this video to help companies break down those critical items that are faced by the underground infrastructure industry. By better understanding these hidden dangers and the critical importance of proper preparedness in confined space, companies can provide the safest work condition possible while working in an extremely and ever-changing environment.

To learn more and to watch the video, please visit NASSCO.org/Safety.