Improving the Marine Environment: HDD Under the Victoria Harbour

British Columbia’s Capital Regional District, a regional municipality that includes Victoria, the province’s capital, is in the midst of a $765 million, multi-year, Wastewater Treatment Project to provide tertiary treatment for wastewater prior to its discharge in the Strait of Juan de Fuca.

The CRD, as the district is referred, is the last major coastal community in North America that discharges untreated sewage into the marine environment. Benefitting the core area municipalities of Victoria, Esquimalt, Saanich, Oak Bay, View Royal, Langford and Colwood and the Esquimalt and Songhees Nations, the project is being built to comply with federal and provincial wastewater regulations by Dec. 31, 2020.

RELATED: PW Trenchless Helps British Columbia’s Trenchless Market Grow

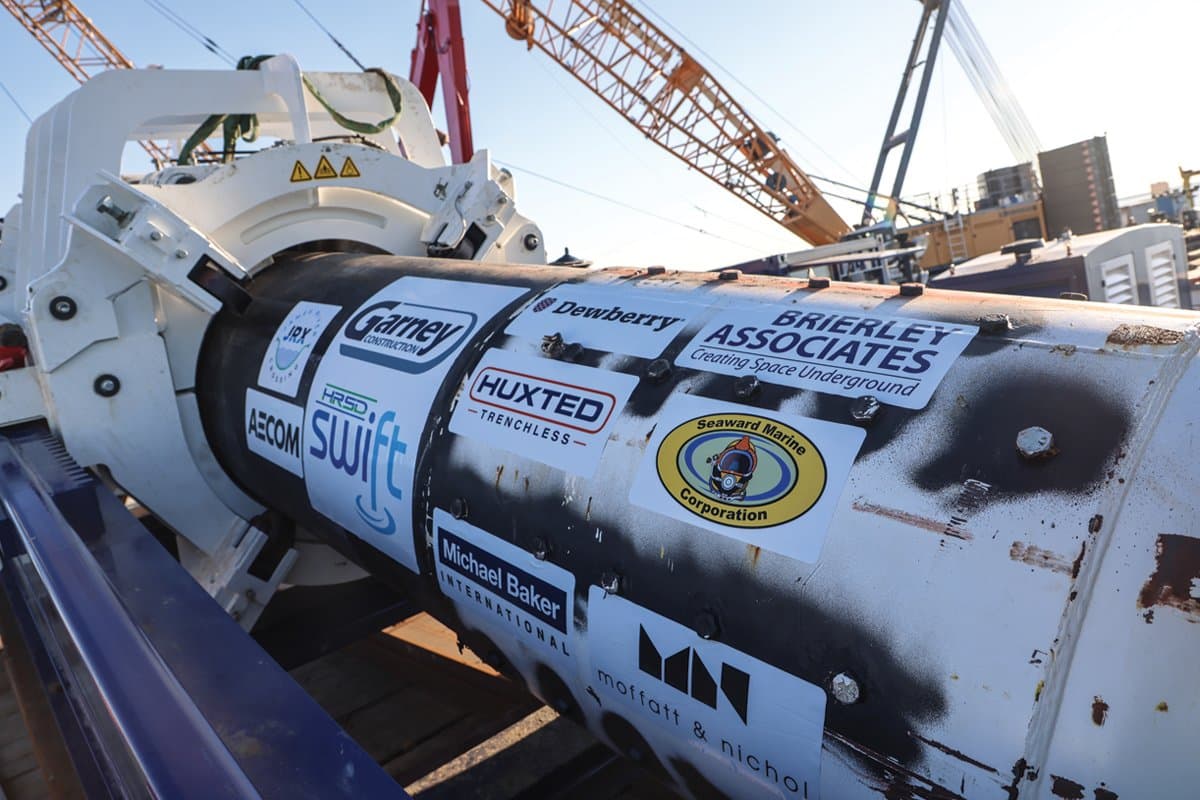

A key component of the overall project is the construction of the McLoughlin Point Wastewater Treatment Plant, in Esquimalt. The plant is being constructed by Harbour Resource Partners a consortium of firms including – AECOM Canada, Graham Infrastructure, HRD/CEI, SUEZ, Graham Capital and Michels Canada. When complete the plant will connect to the Clover Point and Macaulay Point pump stations and treat up to 108 megalitres a day.

In order to connect to Clover Point, an undersea pipeline across Victoria Harbour was required between Ogden and McLoughlin points. Due to the location and volume of marine traffic — including a busy cruise ship and ferry terminal — trenchless technology was the preferred method. It was decided horizontal directional drilling (HDD) would be the only viable option.

RELATED: Vancouver, British Columbia, Adds Trenchless Construction Methods to Its Toolbox

Michels Canada was subcontracted using a design-build approach to execute the 940-m HDD under Victoria Harbour. The restricted available workspace required the HDD to have a complex curve geometry to enable precise entry and exit point requirements by the owner coupled with extremely limited pipe management space in downtown Victoria.

The final HDD design included an entry angle of 18.5 degrees and an exit of 12 degrees with 178 m of tangent and 762 m of horizontal and vertical curve of 1,000 m radius. The project included not only the HDD portion but the pipe makeup and management of the 42-in. by 1-in. steel pipe single pull section.

The formation identified throughout the crossing was extremely challenging. The extensive geotechnical program required boreholes and rock testing as well as probing that confirmed extreme undulations that provided various depth of cover along the final HDD profile. The geotechnical investigation showed highly fractured and low RQD granodiorite with the inclusions of faults. Extensive bathymetric surveys were required for design and to provide Michels with a model which could be trusted.

The final HDD alignment included surface casing on the Ogden Point (pipe side) with the 60-in. surface casing installed starting at 1.8 m below the existing grade and less than 1 m above sea level. This required the HDD rig to be dug into an engineered trench due to site limitations with the back of the HDD rig only meters from the primary cruise ship access for Victoria. The final alignment was just under 80 m below sea level, including approximately 15 m of ocean, 15 m of sediment and 50 m of bedrock. The drilling was completed through hard rock formation, requiring mud motors and hard rock tooling and ended at elevation 4.7 m above sea level on McLoughlin Point.

The final pullback along Niagara Street was extremely narrow, requiring extensive analysis including street level lidar scanning and 3-D modelling to determine the impact to residents, powerlines and existing infrastructure with the final design requiring both horizontal and vertical radius.

The undersea forcemain will convey wastewater from Oak Bay, and areas in Saanich and Victoria via the Clover Point Pump Station and the Clover Forcemain to the McLoughlin Point Wastewater Treatment Plant.

Challenges from the Start

The CRD is on Vancouver Island and, as such, all equipment was brought over on ferries and barges, which created significant logistics issues throughout the project, particularly with the heavier pieces. The HDD portion of the project was completed in one and a half months avoiding the primary tourist season and obvious disruptions to the community that finishing mid-summer would have in this tourist area.

RELATED: Manhole Rehabilitation in Victoria, British Columbia

James Bay, where the 940-m long pipe was laid before pullback to McLoughlin Point, is a densely populated neighborhood in Victoria. It also has an active marina that includes a cruise ship terminal where cruise ships port on route to Alaska and beyond. The neighborhood is well established and one of the oldest in the city, not designed for a large-scale pipeline construction project, especially over a scheduled 60-week duration. If residents and visitors to the popular tourist destination were unaware of the impressive construction project happening in their midst, it was due to extensive project planning by Michels and its partners.

The team effort included the installation of sound wall protection that was designed to look like natural vegetation, limited working hours and strict adherence to the traffic management plan and working with the Anglers Club that shared the boat ramp and provided the only site access to the Ogden Point HDD site. Local sea lions and otters were often curious visitors to the site that went right to the high tide mark.

Michels assembled the 78 sections of 12-m long pipe down Niagara Street, turning the 6- to 8-m wide, house-lined urban street into a securely fenced construction zone occupied by a single point welding station with all the support and testing equipment required to assemble and manage the sections. The road was shut down for approximately one month in order to accommodate multiple sections for pipe makeup and preparation. In order to minimize impacts to the schools and local business cross streets remained open. Michels assembled the pipe into three separate sections and then on the last week welded the sections together and made one continuous section for pipe pull.

A highlight of the project was how residents were engaged in the project when the pipe was strung down the street. A Victoria artist got permission to paint an underwater scene on it. The colorful painting included an octopus, starfish, crab and fish, as well as a note of thanks to the residents of St. James and Victoria who endured the inconvenience of the project shutting down several roads.

The original plan was to have externally coated pipe, but the design and specifications were changed and the 42-in. pipe was internally coated. This allowed for the British Columbia artist to complete her work as well have a kids day where they could come out and put a hand painting on the pipe.

Final pipe pullback required four sidebooms and six cranes to lift the massive section 1.35 million pound section on a compound curve into position for pullback. The pullback required three days with no work at night to minimize impacts on the residents. The pipe reached the McLoughlin Point side on April 19, 2018.