Pipeline Inspection Management: Not Just for the Big Cities

February 17, 2017

The Town of Hillsborough, N.H., is a quiet community of just 6,000 residents. Incorporated in 1772, Hillsborough was the home of the 14th President of the United States, Franklin Pierce, who reportedly claimed he credited his success to his hometown of Hillsborough. The small town intends to expand commercially, attracting more industry to the community. With growth in mind and Collection, Management, Operations, and Maintenance (CMOM) regulations to help direct them, the Town has prioritized the maintenance of its aging wastewater collection system, which includes 19 miles of pipeline, two pump stations and a lagoon wastewater treatment system.

With growth in mind and Collection, Management, Operations, and Maintenance (CMOM) regulations to help direct them, the Town has prioritized the maintenance of its aging wastewater collection system, which includes 19 miles of pipeline, two pump stations and a lagoon wastewater treatment system.RELATED: In-House Crews Tackle Sewer Cleaning, Maintenance for Colorado Springs, Colo.

Like most buried infrastructure in New England, much of Hillsborough’s pipes have been in service for more than 100 years. Successfully repairing and maintaining its century-old distribution system and managing the infiltration/inflow (I/I) that plagued the pipelines became easier and more efficient using a sophisticated, but user-friendly, pipeline inspection management software.

Although not required in every state, New Hampshire communities must meet the CMOM requirements to maintain the town’s National Pollution Discharge Elimination System (NPDES) general permit. CMOM is a framework for municipalities to identify and incorporate wastewater industry practices to better manage, operate, and maintain collection systems; investigate capacity constrained areas of the collection system; and respond to sanitary sewer overflow (SSO) events.

The CMOM approach helps municipal wastewater operators reduce regulatory noncompliance and can help utilities optimize their use of resources by shifting maintenance activities from “reactive” to “predictive.”

In 2009, the Town of Hillsborough, ready to proactively address its infiltration/inflow issues, began working with contractor Ted Berry Company Inc. (TBCI) to implement its CMOM performance goal targets. CMOM planning framework covers operation and maintenance (O&M) planning, capacity assessment and assurance, capital improvement planning, and financial management planning. Information collection and management practices are used to track how well each CMOM activity is meeting the performance goals, and whether overall system efficiency is improving. Activities are reviewed on an ongoing basis, and adjustments are made to better meet performance goals. One of Hillsborough’s CMOM goals was to clean and inspect a certain percentage of its pipe each year. And, according to Paul Dutton — Hillsborough’s wastewater treatment plant facility chief operator since 1992 — “Once you find the flaws, you’d better fix them.”

RELATED: UV-CIPP an Ideal Fit for Rehab Under Maine Turnpike

Although Hillsborough was progressive in the mid-1990s, developing a CCTV inspection program to record the interior of all of its sewer lines, there hadn’t been an effective way to transfer all the video into usable information that could guide and direct the town’s efforts to maintain its pipelines. TBCI implemented a software system for Hillsborough to take existing years of CCTV VHS video and digitize it.

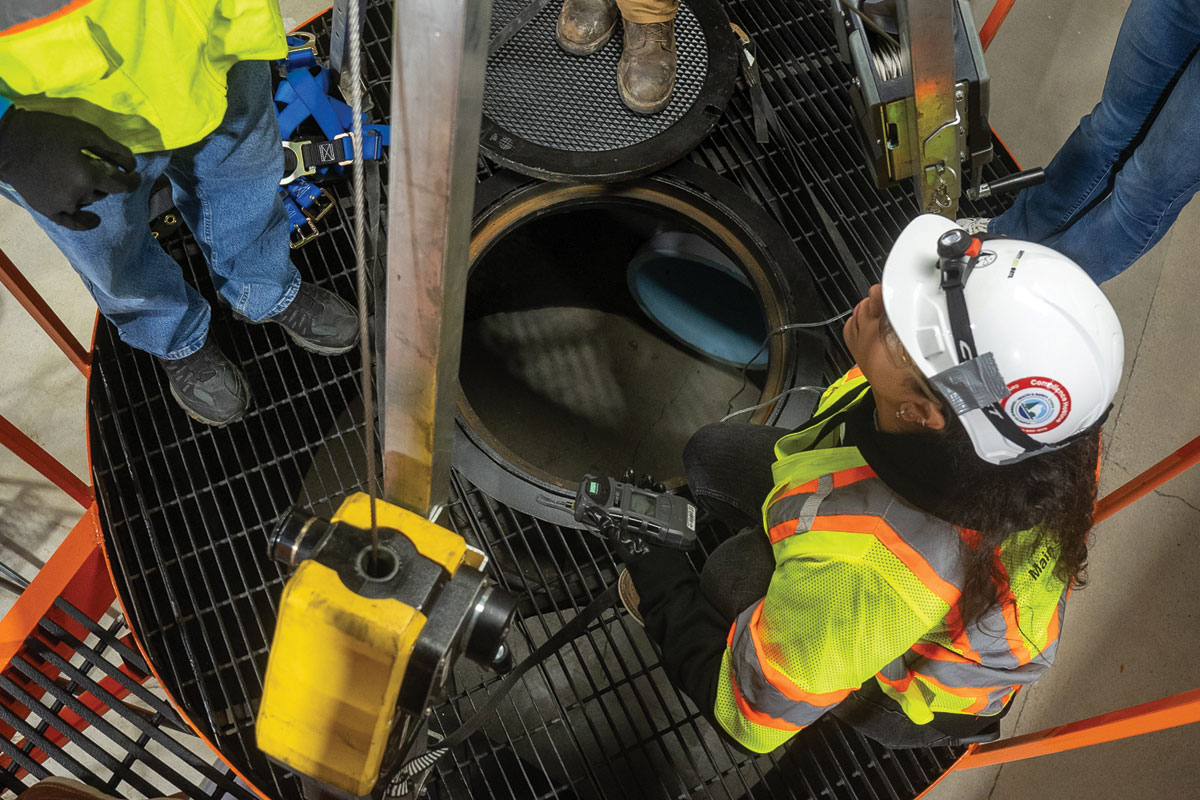

Ted Berry Co. Inc. field service crew assessing pipe conditions using ITpipes pipeline inspection management software and CCTV.

After about one and a half years and not satisfied with Hillsborough’s original software, the contractor switched to pipeline inspection management software that would go far beyond the software that initially helped Hillsborough consolidate years of CCTV footage. Upgrading to ITpipes in 2011 was simple and flexible because Hillsborough didn’t need to have used it from the start; the Town was able to easily transfer the consolidated CCTV footage, and any other information it had collected, to the new software. The new pipeline inspection management software was critical to the success of Hillsborough’s ongoing rehabilitation program.

Most small utilities don’t have an IT professional, an engineer on staff, or an entire department devoted to MIS/GIS. The Town of Hillsborough is no exception. The Town has two wastewater treatment operators who manage the plant, including Dutton, and one sewer department administrator, who handles the billing. Pipeline inspection management software can be complex, making it difficult for non-technical people to use it effectively. With Hillsborough’s current program, multiple non-technical users can use the software and they receive annual training to make a smooth transition with software updates.

Although TBCI is the primary user for data collection with ITpipes, Dutton says: “It’s been an excellent resource to quickly view any section of our sewer line. I can pull it all right up and know where everything is. I can see the condition of each line of pipe, the locations of the manholes, any sags, and distances to service connections. The software rates the problems to help determine how to prioritize our maintenance programs and budget for potential capital improvements. It’s been excellent. It’s all there to help us track everything so we can make decisions, even as a small community. And it’s easy, even for me. I’m not at all a techie and I don’t even have a computer at home.”

RELATED: When a Large Diameter Brick Sewer, Baseball, and Football All Crossed Paths in New England for a Challenging Pipe Cleaning Project

Whether it’s for a small town like Hillsborough, or the City of Los Angeles, the capabilities of the ITpipes software is comprehensive, including data collection, management, sharing, integration and analysis. During data collection, operators in the field use the software, either with a laptop or a tablet, to record data such as the specific location of pipeline cracks, easily uploading photos and video. Field service personnel can have prepopulated inspection projects so existing asset information, such as manhole numbers and pipe IDs, are available in the field, eliminating the potential for data entry errors. The software automatically syncs information from the mobile systems to the office so users can track each time an asset is touched. This assists with ongoing maintenance, operations, and, of course, management.

Management of this information is crucial and often overwhelming, especially because each asset — say, one area of pipe — may have multiple inspections: initial inspection, review after a pipe breaks, inspection after the pipe has been repaired, and then again for an annual follow-up. Each inspection may have hundreds of data points to track: videos, photos, log entries, and reports. The software includes tools for easily tracking this information and the associated files, and keeping the data organized and accessible.

Once the information is collected and securely managed, ITpipes makes it easy to create deliverables after work is performed, sharing information so engineers, treatment plant operators, owners, and others can review results.

The software’s tight integration with ESRI geographic information systems (GIS) is essential, automatically pushing or displaying information onto maps, allowing users to schedule work orders and organize planning for inspection data collection and management. Upon completion, ITpipes can push those completed inspections into an asset management system such as Lucity, Cityworks, Maximo, or other similar systems. Seamlessly sharing data from local inspections with a utility’s higher-end municipal organization applications eliminates cumbersome data transfer or manual efforts to try to organize information. For a utility without an AMS/CMMS system, ITpipes can be used entirely for operations: planning inspections, planning other work crews such as root control, pipe cleaning, CIPP and other projects.

Ultimately, the Town of Hillsborough and others like them use pipeline inspection management software to get actionable intelligence for decision-making that benefits their community’s wastewater collection system. Reporting tools have allowed Hillsborough to filter, query, or report on any information, drilling down into specific reports that are easy to access and available “on demand” via a single-click. While most competitive software includes a limited number of fields allowed in a search report, the ITpipes software has unlimited reporting, and the information can be exported to an Excel spreadsheet for sharing with others or used to create projects with reports, snapshots, and videos that can be provided to contractors or engineering firms for further review. For example, a user could search their database to identify all the pipes in a particular part of the wastewater collection system that runs under a highway within a specified distance from a hospital. The intelligence obtained from this report could help the community prioritize and schedule pipeline work around existing highway upgrades. Exporting reports so they are visualized on a map gives Hillsborough location-based awareness intelligence, simplifying planning and logistics when determining where work or repairs are needed, and where and when to send crews to be most efficient. This feature, called SmartTabs in the ITpipes software, shows the list of all pipes highlighted as lines on a map.

An important benefit to the Town of Hillsborough is that the pipeline inspection management software works with, and keeps current with, compliance systems, which allow for overall pipeline ratings that can be used to determine which pipes in the system require work. With that information easily available, the Hillsborough was able to prioritize their rehabilitation efforts, starting with projects that were easy, obvious, and less costly.

The Town of Hillsborough, New Hampshire, has prioritized the maintenance of their aging wastewater collection system, which includes 19 miles of pipeline, 2 pump stations, and a lagoon wastewater treatment system.

With the help of TBCI, the Town tackled those larger points of infiltration and leaks for about five years, with localized points of trenchless rehabilitation. In pipelines that were structurally intact, more than 40 cured in place sectional point repairs were conducted in locations where grade 4 or 5 defects were identified by the software. In pipelines with more widespread damage, other, more appropriate, methods were used. With the use of ITpipes’ SmartTab feature and GIS software, pipe bursting was deemed the best rehabilitation method on streets with schools due to volume of traffic, capacity of the pipe, and the extent of defects throughout the pipe segment: the proximity of the defective pipe to the school was clearly visible on the screen. Pipe bursting was also used to replace 8-in. vitrified clay pipe (VCP) on Mill Street for the same reasons. Dutton says the results were noticeable immediately.

Eventually, the Town moved on to more significant rehabilitation and repair projects, including full pipeline rehabilitation, pipe bursting, and Ultraviolet (UV) CIPP projects. UV CIPP was successfully used to rehabilitate 1,200-plus ft of 10-in. VCP sewer main on Henniker Street. With heavy traffic, a newly laid pavement, and the depth of the pipes, a 100 percent trenchless rehabilitation was necessary for this project to avoid disruption to the community. The Town of Hillsborough was able to successfully conduct these improvements and repairs as a result of careful prioritization of their asset management.

Dutton is very pleased with the results: “The results for Hillsborough have been huge. Since we did the repairs identified by the software, our flows to the plant have been cut in half,” he says.

Matt Timberlake is president of Ted Berry Company.