In-House Crews Tackle Sewer Cleaning, Maintenance for Colorado Springs, Colo.

Colorado Springs Utilities was the first customer to purchase the Model 900 ECO from Sewer Equipment Co. The utility’s Wastewater Collection Operation and Maintenance group received two of the units in the first quarter of 2016.

Whether they are utility employees or contractor partners, sewer cleaning crews are on the frontlines of when it comes to maintaining sewer infrastructure. The Wastewater Collection Operation and Maintenance group of Colorado Springs Utilities tackles this dirty job for 136,147 customers in the Pikes Peak region.

A four-service public utility since its inception in 1924, Colorado Springs Utilities provides water, wastewater, gas and electric service to the Pikes Peak region of Colorado. It is also the largest single-operator sanitary sewer system in Colorado and some its infrastructure dates to the 1880s.

RELATED: HDD Job Requires Power in Small Footprint

System Background

Divided into three basins – western, central and eastern – Colorado Springs Utilities Wastewater division covers approximately 195 sq miles and treats approximately 40.3 million gallons per day. The system has two wastewater treatment facilities, one solids facility, 19 lift stations, 334 sub basins, 23 miles of sludge lines, 13 miles of force mains and 35,000 manholes. Some sections of the system date to the 1880s.

Like many systems of this vintage, there are several different types of pipe underground including vitrified clay pipe (VCP), concrete, ductile iron, cast iron, PVC, Truss and fiberglass.

For at least 40 years, the Wastewater Collection Operation and Maintenance group has worked in-house, making sure the 1,700 miles of lines are flowing freely. Much of the 43-member crew is homegrown, with the leadership team working their way up from the ground floor.

The leadership team is proud of the fact that much of the 43-member crew hale from the Colorado Springs area.

Like other utilities across the country, Colorado Springs Utilities leadership strives for a proactive rather than a reactive approach to maintain its infrastructure. The wastewater collection system initiatives include the Local Collectors Evaluation and Rehabilitation Program, Collection System Rehabilitation/Replacement and the Manhole Evaluation and Rehabilitation Program.

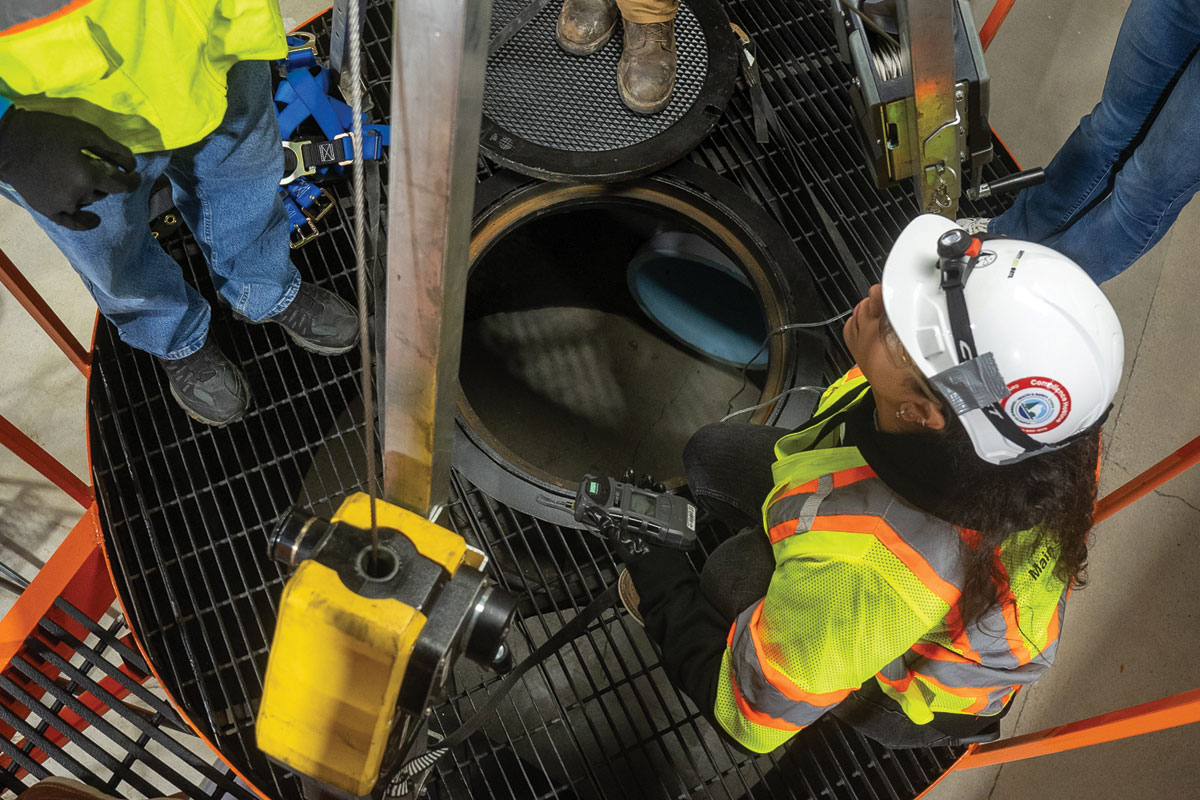

“In the last 40 years, our cleaning program has changed greatly, thanks to technology advancements,” says Nick Verdi, operation supervisor of the central basin. “We used to have to enter the manhole to clean and bucket the sewer lines. Now, we have combo units, which prevent our guys from going into the manholes, which is a safety issue and the last thing that we want to do.”

Rounding out the leadership team is Carlos Wright, superintendent; Rob Paraggio, operation supervisor for the eastern basin; Dave Dunlap, operation supervisor, western basin and Isidoro ”Chopper” Cometto, supervisor of the hydro excavation crew.

“Every program we manage — root control (since 2010), grease release, CCTV, recon, quality control and cleaning – we complete with internal staffing,” Paraggio says.

RELATED: How Colorado Springs Funded Its Landmark Southern Delivery System

On the Job

Wright and his employees handle the reconnaissance CCTV work before cleaning takes place and they also determine the level of cleaning necessary. The Wastewater Collection Operation and Maintenance crews serve as the data acquisition team for the Wastewater division’s engineering team, which analyzes and codes the system to NASSCO standards and determines what repairs, if any, need to be made.

Using Aries cameras and IT Pipe software, the inspection end of operations has grown rapidly. From manually pulling cameras on skids through the pipe to coding via microphone and saving to VHS tape — not only has the technology improved but the evaluation, as well.

In addition to sewer cleaning, the Wastewater Collection Operation and Maintenance group is charged with hydro excavation work for Colorado Springs Utilities.

One of the places the technology shift in the last decade is most evident is on the mapping end. Previously, the crews would rely on map books, which were often outdated. Now, crews have timely, near real-time, mapping data on their mobile laptop units. Included in the data is also history of the section of pipe they are working on.

“It has evolved over the years and our group is charged with providing our engineering department all of the data,” Verdi says. “They assess it and determine how we will repair deficiencies with capital funds, or if the pipe will be accepted into the system.”

When deficiencies are found, the in-house crews can handle pipe patching and manhole rehabilitation. Contractors handle larger cured-in-place pipe (CIPP) and other relining projects.

“The eyes in the pipe have helped us a lot. With those cameras, we perform recon before the pipe is clean, so we know how to clean it,” Verdi says. “It will tell us if we need to perform root control, fats, oils and grease treatment or if there is a need for the combo truck.”

Pipe type and age, the presence of businesses, apartments and food chains, which have an increased amount of fats, oils and grease (FOG), and likelihood of higher root intrusion determine how crews work through the system. There are eight sub basins — based on this criterion — which crews visit for cleaning each year and the crews can get through the entire system in five years.

“The pipe that has more wear and tear would be our older pipe, which is VCP. VCP breaks at times when cleaning it. It also encounters root infiltration at the joints and at the connection of the tap,” Paraggio says.

RELATED: This California City Built Its Preventative Maintenance Program from Scratch

For VCP, the crew typically chemically treats for roots — a less aggressive method that minimizes wear and tear on the old pipe — or uses a root saw. If grit or grease is present, they use a grease release chemical along with the high-pressure water from the jet truck. Typically, in the PVC, ductile and cast iron sections, crews combat grease and grit and in the Truss sections it is typically root intrusion and it is treated similarly to the VCP.

Leading the Wastewater Collection Operation

and Maintenance group for Colorado Springs

Utilities are, from left, Rob Paraggio, Dave Dunlap, Isidoro Cometto, Carlos Wright, and Nick Verdi.

New Equipment

“Even with these advancements, it’s not always pull-up and go. We wish it was, but there are obstacles out there that our guys run across to CCTV or clean the main lines,” Wright says. “A lot of them over the years have become way more manageable with the easement carts that we obtained through Sewer Equipment Co. We also have the experience and knowledge of our guys over the years who know where these manholes are, as well as pre-planning and scheduling.”

It also helps increase productivity that Colorado Spring Utilities has a local solids handling and disposal facility that it built, to allow the debris to dry — with the liquids running off into the treatment plant – before shipping it to a disposal location via dump trucks. In the past, one combination unit could spend at least one hour a day on the road transporting solids to a disposal facility.

“In the last decade, our collection system has improved. We’ve had many lines relined with CIPP and this will give our infrastructure the integrity it needs and give us many more years,” Paraggio says. “We’ve also added new pipe to our system due to growth in the region. We’ve added a new treatment plant. We’ve rehabbed our manholes and we’ve added lock down manhole lids to prevent vandalism.”

Though technologically forward thinking, when it came time to replace two of the combination units the leadership team, as well as the boots on the street, tested a variety of new offerings. They favored the Model 900 ECO from Sewer Equipment Co. of America as it is one of the simplest to use combination units available on the market, according to Wright.

“We demoed many trucks and our guys preferred the basic Sewer Equipment truck,” Verdi says. “It still offers a lot of the bells and whistles you can’t do without, but it has simple levers and controls and is not over-engineered.” This, the leadership team notes, is important because more change in systems means more time away from the streets for training.

RELATED: AEM Launches Sewer Cleaner Marketing Statistics Programs

“We put it in our guys’ hands and we had to make the best business decision that will offer the most bang for the buck for years to come,” Wright says. “We have to assess budget and replace what is most critical amongst our entire fleet. Older vehicle replacement was every two years now we have to assess the biggest needs of our group and it may be a 3 1/2 year gap.”

Easement machines from Sewer Equipment Co. make cleaning hard to reach manholes a breeze. The group uses its two easement carts to clean hard to reach manholes that are in backyards or tight alleyways.

In early 2016, Colorado Springs Utilities was the first public owner of the Model 900 ECO, Sewer Equipment Co.’s first combination sewer cleaner. It received the first one in January 2016 and the second that March. This adds to a fleet that already includes two easement carts, two pump trucks and two root control trucks – all from Sewer Equipment Co.

Was there some trepidation over being the recipients of the first truck? Wright likened it to buying the first year release of a car, but said they were not concerned, based on Colorado Springs Utilities’ relationship with Dawson Infrastructure Solutions Inc. the Sewer Equipment Co. dealer in the Denver area.

“Kelly Dawson (president) and his No. 1 guy, Monty Hill worked with my guys to make sure things were taken care of and adjustments were made,” Wright says. “Dawson Infrastructure Solutions helped with any issue and we also used its Train the Trainer program to get acclimated with the equipment.”

Wright adds that the Dawson Infrastructure Solutions team essentially held the truck’s “hand” through this first year of ownership. “We were confident, based on the service we had received from Dawson Infrastructure Solutions in the past that we would receive a high-level of support no matter if it was a chassis-related issue or a Sewer Equipment -related issue for as long as we own the truck(s).”

Taking the new equipment and improved technology into perspective, the leadership team has worked to fine tune the cleaning and maintenance program – cleaning on average 5 million ft per year. With this proactive monitor, clean and maintain mindset, mainline stoppages have dropped from 66 in 1997 to two in 2016.

Mike Kezdi is associate editor of Trenchless Technology.