Strategic Selection of Technologies to Assess Large Diameter Sewers

The collection system inspection services industry has made significant advancements in developing tools and techniques to thoroughly assess the condition of large diameter sanitary sewers.

Multi-sensor-based platforms that were considered specialty tools a decade ago are now being considered mainstream and provide a cost-effective inspection option available to many municipalities.

This observation, however, should not be construed as downplaying the role of established and proven technologies. In fact, the best approach is to design a multi-pronged strategy that makes optimal use of all the tools in the toolbox.

To this end, this article provides an overview of technologies used for assessing large diameter sewers (greater than 36-in). Best practices, based on lessons learned and considerations will also be presented to help select the right tool for your project.

RELATED: NASSCO Report: Man-Entry Pipe Inspection of 120-in. Sewer with a SCUBA Diving Team

Sewer Condition Assessment Tools

Desktop Level Screening

Before committing to an in-field assessment, one may choose to conduct a desktop-level screening. This exercise uses office-based tools, such as computerized maintenance management systems and geodatabases, to identify pipes with higher likelihood of failure. This assessment would then be used to justify a targeted field inspection program.

Desktop-level assessments compare a pipe’s age against its anticipated service life. Service life is derated based on factors such as pipe material, geotechnical data, and maintenance history.

When implementing a desktop-level screening, consider the accuracy of GIS attribute data. GIS data may be an assumption made by a database manager. Prioritize the use of attribute data that is supported by record documents or field verifications.

Person Entry Assessment

Person-entry assessment involves deploying a team into a pipe and physically assessing condition. Safety during this type of assessment is paramount; extensive planning is required prior to mobilization. At a minimum, the team will photograph the pipe interior and make visual observations.

Advanced assessments may also include conducting electromagnetic and/or ultrasonic inspections to measure wall integrity. For concrete pipes, one may also take concrete core samples for ASTM C39 compression testing.

Inspector qualifications are important when assembling the assessment team. At least one inspector should be certified through NASSCO’s Pipe Assessment Certification Program (PACP). This inspector will ensure data is collected in accordance with best practices.

RELATED: CDM Smith: Seven Decades of Engineering Solutions

It is helpful to have a structural engineer on the team as well. Structural engineers conduct tactile inspections to better understand pipe deterioration mechanisms. Furthermore, structural engineers can identify repairs that may be required before implementing full rehabilitation solutions, such as cured-in-place-pipe lining or spray-applied lining.

A common question is the minimum diameter for a person-entry inspection. Based on experience, entry is challenging for pipes smaller than 48 in. in diameter. Consideration should be given to using crawler-based (remote) equipment when person-entry is not feasible.

Remote Assessment

Remote assessments are accomplished by crawlers or floating platforms that carry tools to assess the pipe. Person entry is not required. Platforms are either propelled by a motor or pulled by a winch.

The most common technology to remotely assess condition is closed-circuit television (CCTV) cameras. When deploying a CCTV camera, one should specify image resolution and the ability to adjust lighting while in the pipe.

Furthermore, the inspector should be PACP certified and follow data quality procedures presented in Section 1 of the PACP Manual.

For larger diameter pipes, digital imagery may not be sufficient to fully assess condition. For more advanced assessments, the platform can be equipped with tools to complete a multi-sensor assessment. As using additional sensors will increase cost, one should understand the cost and benefit of using more sophisticated tools. Sensors that are used during a multiple sensor assessment include:

- LiDAR/Laser – LiDAR and laser are tools that emit a signal to measure pipe profile above the water level. In general, LiDAR is used for larger diameter pipes and laser for smaller diameter pipes. Measurements map the wall profile to quantify wall loss or mineral deposits.

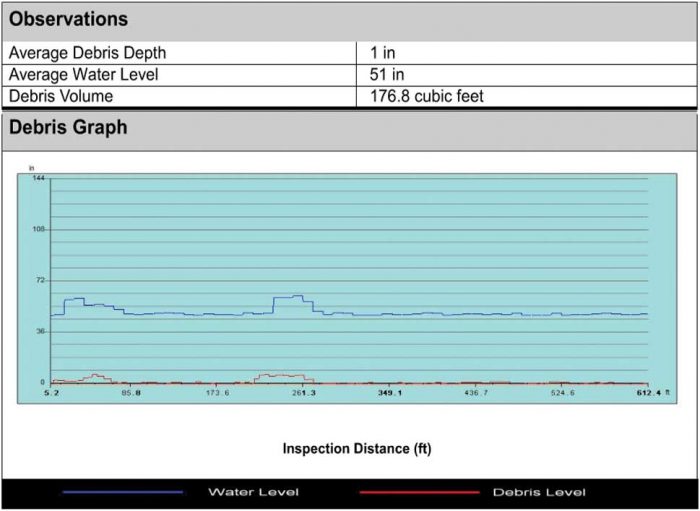

- Sonar – Sonar emits an acoustic signal to map debris or defects below the water surface. A common use for sonar is to quantify debris that are not apparent from a CCTV inspection.

- Pipe Penetrating Radar (PPR) – PPR emits an electromagnetic signal through the pipe wall to measure wall condition and detect voids outside the pipe. The PPR unit must touch the entire pipe wall, so there is a maximum diameter for using this technology. If exceeded, one would need to enter the pipe and manually record PPR measurements.

- Gas and Temperature Monitoring – Gas (H2S) and temperature monitors can be added to the multi-sensor assessment unit. These monitors take readings along the pipe alignment. These sensors provide context when assessing corrosion apparent in LiDAR/laser or CCTV data.

An important consideration when implementing a remote assessment is data processing time. CCTV data is often coded in the field and reports are generated shortly after the assessment. Advanced technologies often require more time for data processing. It is common to experience a lag of four to eight weeks between inspection and report delivery.

In addition, quality control is critical. Data quality from a CCTV inspection can be controlled by requiring an inspector to adhere to PACP standards. Similar standards are not available for other multi-sensor tools. Instead, one should evaluate the contractor’s qualifications, experience, and work products developed on previous projects. This evaluation will allow you to become comfortable with the type of data that you will be receiving at the end of your project.

RELATED: NASSCO Report – Large Diameter Sewer Condition Assessment

Strategic Technology Selection

It is important to be strategic when selecting the right technology for your project. Consider the following:

- Is bypass pumping required to implement the assessment? Will the cost of bypass impact the cost-effectiveness of the project?

- What degree of person-entry is required to deploy an assessment tool? Will someone need to access a manhole or the entire pipe to complete an assessment? What is the safety risk?

- If the contractor is retained through an open bidding process, is there qualified competition for the selected technology in your market? If not, is a sole-source contract acceptable?

- Is the data that will be provided sufficient to evaluate the pipe? If not, consider a more advanced tool. If the tool provides data that you will not use, consider a lower-cost option that is more compatible with your needs.