NASSCO Report – Large Diameter Sewer Condition Assessment

Large-diameter pipe typically greater than 36 in. will inherently have a higher level of criticality and lack of redundancy to reduce pipe flow levels. These larger assets also typically exhibit a higher level of corrosion and debris build-up, as most are not easily maintained by internal city or municipal forces. They are also expensive to rehabilitate, so more detailed condition assessment information is required to make the decision when rehabilitation is necessary.

The use of multi-sensor inspection (MSI) technologies for condition assessment will help provide this information. The MSI platform provides a variety of sensors that collect data in one inspection pass. MSI typically incorporates higher resolution CCTV to compensate for the greater focal distances to the pipe sidewall periphery.

RELATED: NASSCO Report – The Use of Unmanned Aerial Vehicles in Below-Ground Structures and Pipe

The MSI platform will also have LASER and SONAR on board to provide supplemental inspection data streams. The CCTV, LASER and SONAR suite of tools are mounted on a common platform and allow the simultaneous inspection below and above the sewage level for the entire pipe interior (providing sufficient sewage level is present to obtain SONAR data).

SONAR imaging provides levels of debris and pipe shape below the water line, whereas LASER can provide dimensional information of the pipe structure and shape above the water line, which is valuable in advanced structural assessments and in determining remaining useful life.

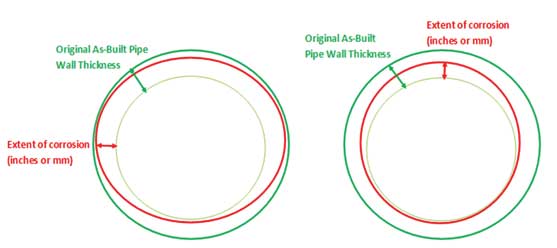

LASER scan technology provides measurements that are used to create a three-dimensional (3D) representation of the pipe, and when overlayed with record drawing dimensions, a virtual mandrel is created and used to calculate any dimensional change in pipe cross-sectional shape.

As such, the LASER scan data is typically presented as cross-sectional comparisons and is also presented as folded-out flat views, or as 3D drive-through models of the entire pipe segment, to help the reader discern changes in pipe cross-sectional shape and the extent of corrosion or buildup on the pipe wall surface. Measurements are typically thematically colored with legends to represent the amount of pipe dimensional deviation with clock position presented on the y-axis to orientate the data. LASER measurement positive values extend outside the pipe, which can indicate corrosion to the pipe surface. Negative values extend inside the periphery of the virtual mandrel to represent buildup or encrustation.

RELATED: NASSCO Report – Lafayette & White River Large Diameter Sewer Rehab Case Study

Care should be taken, however, when inspecting non-uniform pipe assets (such as monolithic cast-in-place pipe) as the virtual mandrel may present high levels of ovality when, in fact, those conditions may not exist. This supplemental data stream should always be used in conjunction with the same payout distance of the CCTV to discern actual pipe wall loss; from direct evidence of missing bricks to Hydrogen Sulphide (H2S) attack as corrosion/erosion; or deposits such as fats, encrustation, or silt build.

One recent project provided an opportunity to analyze portions of a 54-in. diameter pre-cast concrete Interceptor line, comparing MSI results with a 10-year time difference (2011 and 2021). Efforts to align both inspections were completed, given inspections were completed in opposing directions. A direct comparison of payout raw data was then completed to allow dimensional comparisons to areas of known points in the pipeline. This analysis determined that there was an average pipe wall loss between half- to 1-in. of corrosion/erosion throughout the segments over that 10-year period.

Sedimentation accumulation was evident from the SONAR results, and CCTV visuals also confirmed sediment at the haunches. Surface aggregate projection or missing areas observed by the CCTV correlated to LASER readings which proved and quantified actual pipe wall loss due to H2S attack throughout the segments.

Debris levels can create further problems outside the obvious loss of pipe capacity. The sewage flow has carved a channel through the debris and results in a flat, broad, flow stream under low flow conditions. These low flow conditions can result in a sewer environment that is more conducive to hydrogen sulfide production; low or stagnating flow can result in depleted oxygen levels in the sewage, turning the environment anaerobic and resulting in the production of hydrogen sulfide gas, and subsequently, sulphuric acid that can corrode the concrete interior.

RELATED: NASSCO Report – Spiral Wound Liners for Pipe Rehabilitation

For the NASSCO PACP-certified professional who is reviewing and analyzing this data, it is imperative they have a good understanding of LASER and SONAR results, and to know how to interpret the results when comparing with the PACP-coded CCTV visuals. This LASER and SONAR data can also be supported within the NASSCO PACP deliverable. Further, it is imperative that LASER and SONAR are correctly aligned with the cable calibrated distance of the CCTV inspection to allow direct comparison and minimize any misinterpretation and/or ambiguity.

LASER scan technology needs to be assessed for use depending on the pipe material and inspection drivers, such as to assess the need for rehabilitation. LASER is useful to determine the extent of corrosion in RCP pipe but typically provides less useful information when inspecting lined or VCP pipe, for example. While LASER reinforces many decisions on whether rehabilitation is required, it often does not change the selection of the chosen rehabilitation method.