NASSCO Report: Man-Entry Pipe Inspection of 120-in. Sewer with a SCUBA Diving Team

CDM Smith has been working with the City of Columbus, Ohio, over the past year to inspect and assess the condition of the Scioto Main, a 120-in. reinforced concrete pipe (RCP) sanitary sewer that flows into one of its two wastewater treatment plants.

This sewer is one of the most critical assets in the City’s entire collection system. Although the sewer is only about 15-years-old, it is plagued with numerous PVC lining failures which are partially blocking the flow and periodically showing up at the Jackson Pike Wastewater Treatment Plant (JPWWTP) intake screens.

Several CCTV and sonar inspections performed by Hydromax USA were unable to be completed because of these severe blockages. Reverse setups were not able to be performed because there was no way to float a rope for the winch to pull the CCTV pontoon unit. The initial video from upstream showed approximately a 4-ft long section (270 degrees) attached only from the 7 o’clock to 9 o’clock position. This sewer has dry weather flow of 48-in. – 30 million gallons a day (mgd) – and high hydrogen sulfide concentrations.

The City requested that this sewer segment be inspected and for CDM Smith to find a way to do this even if it took man-entry. Because of high flows and high hydrogen sulfide concentrations, this task was extremely dangerous and extremely challenging. CDM Smith and Hydromax USA got in touch with Bulldog Diving Inc. a specialty diving company that is experienced in these types of dangerous projects. After several weeks of planning, Bulldog Diving arrived in Columbus, Ohio from their Indiana headquarters.

Because this 7,600 lf section of sewer is the last sewer main before entering the JPWWTP, the team coordinated with the operations department to pump down and lower the wet well to minimize the flow levels in the 120-in. sewer. With constant oversight from the CDM Smith team, they performed CCTV video inspection with a helmet-mounted camera connected with a coaxial cable to the monitor in the truck.

The diver had five lines connected to him including two supplied air hoses, a safety rope, CCTV cable and a pneumatic air hose for tools. The diver’s helmet was equipped with an LED light, camera, and communication cable to allow constant communication between the diver and the team above ground. Members of the team above ground were able to see in real-time what the diver saw and communicated instructions to him while he was in the pipe.

Diver Deployment

The diver entered the downstream manhole (0040S0344) to determine if he could safely walk upstream to the known PVC liner blockage at approximately 300 ft upstream of manhole 0040S0294 and 315 ft downstream of 0040S0344. A ladder was placed in the manhole at the exit side of the manhole to allow the diver to catch himself should he lose footing and not get swept downstream.

RELATED: City of Shreveport, Louisiana Takes on $500 Million Sewer Rehab Project

Because of these high flows it was extremely hard to walk upstream but it was the shortest distance to get to the blockage. To assist the diver, the team floated a kayak with a tethered rope downstream from the upstream manhole (0344) to the downstream entry manhole (0294). With the kayak and tethered rope, the diver began using the rope to help him walk upstream through the 30-mgd flow. The kayak was also essential to carry a large toolbox with numerous tools. Three of the team members pulled the kayak upstream with the diver’s tools while three other team members communicated with the diver and the upstream manhole crew.

There were three primary tasks requested of the diver:

- Cut and remove the blockage if possible.

- Assess the amount and consistency of debris as he walked on top of it.

- Perform compressive strength testing with the Schmidt Hammer.

As the diver traveled upstream through the pipe he stated that he was walking on top of two feet of gritty settled deposits which put the sewage at approximately 3.5 ft high. As he continued to walk upstream he entered an area with less sediment, causing the water to be about 4.5 ft high. When the diver reached the downstream portion of the blockage, he could not walk on top of the slippery failing PVC liner. Thus, to get past the blockage, the diver climbed onto the kayak, which gave the three-team members a strenuous workout.

As the team pulled the kayak, the diver’s lines got tangled on the PVC liner and tipped the kayak over causing the diver to backflip off the kayak. “Diver down,” the crew chief yelled and the team, in turn, yelled for the upstream manhole team to stop pulling the kayak. Although most people would never attempt this dangerous work, these professionals handled the situation very calmly and professionally. The diver gathered composure, caught his breath and continued upstream to the beginning of the hanging PVC liner.

After the diver reached the area where the liner was missing, he began cleaning the pipe on both sides to perform the Schmidt hammer tests. The diver used a combination of a reciprocating tool and wire brush to get to the exposed bare concrete.

At left, the diver from Bulldog Diving Inc. cleans the pipe wall to prepare for Schmidt Hammer testing. At right, the diver performs the Schmidt Hammer test.

Assessing the Pipe

After the test area was cleaned, the diver was instructed to take six measurements with the Schmidt Hammer tool on both sides of the pipe, at about the 2 o’clock and 10 o’clock positions. Using the calibrated chart of the rebound values, the concrete was estimated to be approximately 7,000 psi compressive strength. The values were very consistent on both sides of the pipe.

As initially thought, the lining blockage was only about 4 ft long, but the diver was able to surmise that the lining was more than 40 ft in length (firmly attached from the 7 o’clock to 9 o’clock position) and very difficult to cut and/or remove.

RELATED: London Bridge Uses Timber Headings for Sewer Upgrade Project

A 2-ft by 2-ft piece of the liner was laboriously cut out with a reciprocating saw and brought back to the surface for evaluations. Since it would have taken many hours to completely remove the blockages, it will be done during the rehabilitation phase of the project instead of the assessment phase. This effort was a monumental feat and will provide essential data to better understand the future effort in removing all loose portions of the failing PVC liner and the time and materials that may be necessary to achieve this.

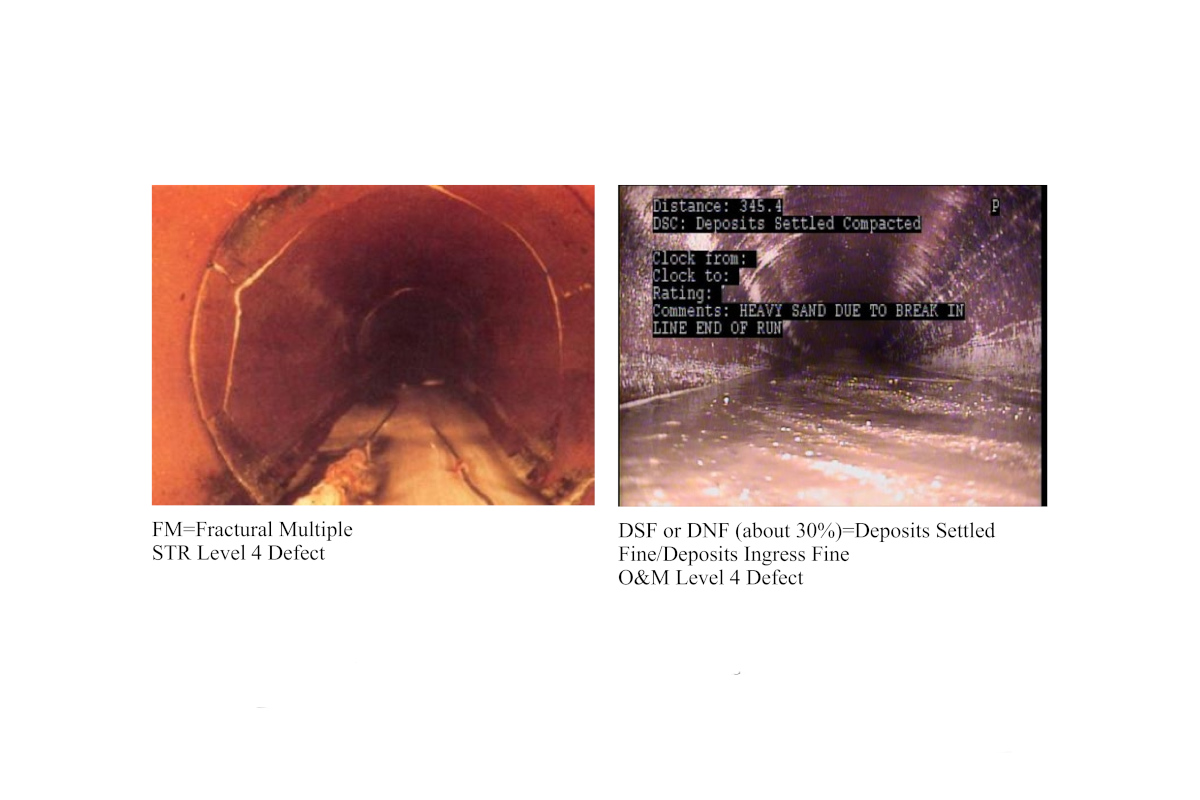

The diver had live video feed that was recorded and edited to create a quality .mpg video file. This video was used to code the PACP defects and pipe attributes per PACP standards and added to the City’s sewer PACP database.

The diver had live video feed that was recorded and edited to create a quality .mpg video file. This video was used to code the PACP defects and pipe attributes per PACP standards and added to the City’s sewer PACP database

The diver inspection provided numerous valuable pieces of information critical to the assessment and developing alternatives and costs for rehabilitation of this critical sewer. The team now has a better sense of how difficult it will be to remove the Linabond. The team confirmed what the sonar data told them about the amount of debris but also provided information about consistency of the settled debris in the sewer. The Schmidt Hammer testing provided compressive strength information on the exposed concrete.

While most people would not ever consider doing this type of work, for these brave professionals, it is all in a day’s work.

John Schroeder, P.E. CDM Smith, is a member of the NASSCO Infrastructure Condition Assessment Committee.