City of North Olmsted, Ohio, Makes Maintaining the Manholes a Priority

One Northeast Ohio city is not taking the deterioration of its manholes lightly. The City of North Olmsted is doing everything it can to ensure that these aging structures are properly inspected, maintained and rehabbed.

North Olmsted — a 11.7-sq mile suburb located west of Cleveland — is home to more than 32,000 residents. The sanitary sewer system that serves the community, as well as two abutting communities, was constructed in its present-day form during the mid-1960s using vitrified clay pipe initially and later PVC. The system was completed in 1974.

RELATED: Avon Lake Regional Water Applies Unique Lateral Loan Program to Address Sewer Overflows

Overseeing the manholes and the entire sanitary sewer system is North Olmsted collections systems foreman Greg Peters. He has worked for the city sewer department for 18 years and has made it his mission to make sure inflow and infiltration (I/I) becomes as minuscule a problem as possible.

When describing the City’s sanitary sewer system, Peters says the system is in good condition; however, longstanding I/I issues are currently being addressed through the City’s comprehensive five-year plan. I/I is being targeted and attacked by crews through the program.

“Years ago, we had a big problem with sanitary sewer overflows,” says Peters. “We were addressing those and did a huge treatment plant expansion in 2010 and we got those under control. Part of that [project] was determining where the I/I was coming from and addressing them.”

Through thorough CCTV investigations, the City was able to determine that majority of I/I was emitting from its manholes. North Olmsted has approximately 2,800 manholes that it maintains. “On an ABC scale, I would say that there is nothing worse than a C minus,” Peters says of what they found. “Of course, some are worse than others and there is wear. It’s a proven fact that most of your I/I comes in the top 3 feet of a manhole, so that is what we are trying to address.”

Beginning in 2013, the City initiated an inspection and CUES cleaning program for its manholes. Each manhole was inspected, with crews sent out with CUES cameras during downpour rains or heavy melts to evaluate the manholes for I/I. The condition of each manhole was documented and given priority of low, medium or high. Those deemed the highest priority were put at the top of the list to be addressed and repaired and/or rehabbed.

RELATED: Social Networks Connecting the Trenchless Industry Across the Globe

“Right now, if we consider the manhole is a high priority, we address it immediately,” Peters says. “Everyone we are doing this year or have already done in past years, was given a grade of a high priority. Those given the lower grades of low and medium have not been repaired yet. We are trying to get to as many as we can that are deemed high priority. We are attacking the list.”

In 2017, 138 manholes were rehabbed. “That’s a lot,” Peters notes. “The work is all done through manual hand labor.”

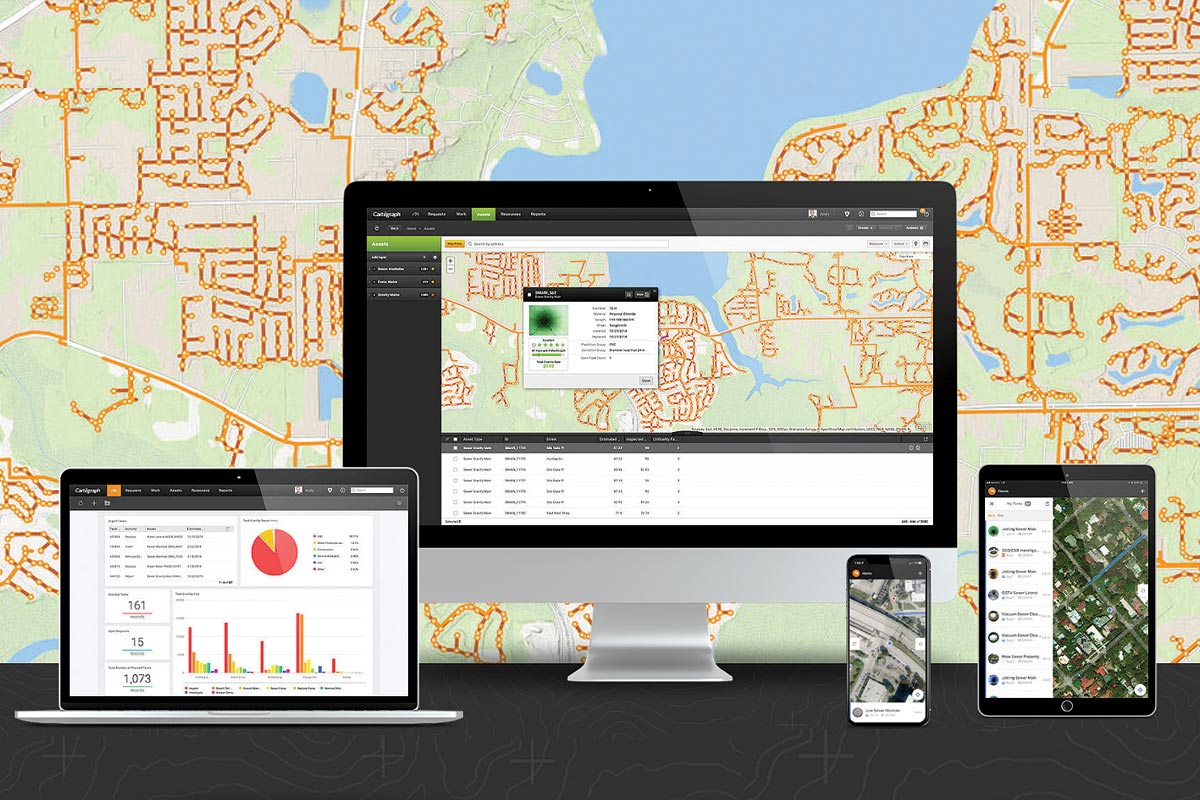

The color-coded map that Greg Peters uses to keep track of what pipes have been cleaned and inspected.

Peters, who started his career as a CCTV operator, says his crews fill out an inspection check sheet for each manhole, which includes questions about overall condition, does it have a precast chimney, are bricks missing, etc. Each manhole was meticulously inspected for defects and problem areas because, as Peters notes, no two manholes are alike.

“All manholes are unique, from the mortar to brick,” Peters says. “What we found was that some of the manholes were completely deteriorated and we had to rip out the entire [manhole] chimney. If the chimney is beyond repair, we are taking out the sidewalk slab where ever it may be, such as a road, tree lawn or sidewalk and putting concrete precast risers back in and treating those.”

RELATED: In-House Crews Tackle Sewer Cleaning, Maintenance for Colorado Springs, Colo.

As for how the manholes conditions were addressed, Peters did his homework. He attended a Sewer Pipe Users Group event and met with trenchless vendors and demos done to see how products were used. The City turned to Source One’s Pipe Patch technology for its point repair work for mainline projects and Source One’s XSeal and Sealguard for the manholes, as well as Sauereisen’s F 121 and F88.

Source One’s XSeal is a single component, hydrophobic polyurethane sealant. Used as an adhesive and sealant, the product successfully locks out infiltration within joints between pre-cast concrete and manhole riser rings. SealGuard II, a polyurethane grout, designed for high inflows in precast, cement or brick underground infrastructure to effectively seal active infiltration and leakage in even the smallest fractures. Opposed to covering a leak, SealGuard II is injected directly into the flowing water, causing the infiltration to instantly stop.

Sauereisen F121 is a high-strength substrate repair material designed for an economical repair where deterioration is greater than small voids, bug holes and irregularities in concrete or brick substrates. F-121 repair material is designed as a water-resistant barrier to aid in the prevention of inflow and infiltration. F-88 is an elastomeric lining composed of fiber-reinforced, asphalt-modified urethane. ChimneySeal is used as a chemical-resistant membrane or gasket seal for the prevention of water infiltration.Among the challenges Peters and his crews have faced during this process is 1) locating all the manholes, as many were not in plain sight but constructed in roadways and wooded areas and 2) just getting educated on the processes and products on the market.

RELATED: Tech Forum: Controlling I/I in Municipal Manholes

“There are so many products out there. We needed to find the right products for our situation,” he says.

The program is working as planned, Peters says. A flow meter study early on during the program showed a 50 percent reduction in the areas where manholes were addressed. “Our long-term plan is to eliminate as much I/I as possible,” he says. “We know we can’t stop it all but we are doing our best to make it as close as possible.”

As for what he has learned over the course of the last four years of undertaking the City’s manhole program, he says this: “You can’t say you know what you’re going to do until you open the lid and look. Every manhole and its condition are different.”

Sharon M. Bueno is managing editor of Trenchless Technology.