HDD Locating & Golf – How to Hit a Hole-in-One

A hole in one is a rare feat. It takes the perfect combination of skill, equipment, planning, luck, and timing. Even with these factors firmly in place, many golfers will play their entire lives without achieving this distinction.

Horizontal directional drilling (HDD) contractors often do not have the luxury of a second or third stroke, many contractors see efficiency robbing signal interference as an accepted fact of HDD operations. They have grown accustomed to losing signal halfway through a bore, pulling back and starting over. It’s simply a fact of life for many contractors and they often believe certain projects are too challenging for a walkover system.

California HDD contractor Underground Boring Systems (UBS) defies these odds and prides itself on pursuing complex niche projects. Their operating philosophy is that with proper planning, the right tools and expert support, they can finish projects their competition can’t. This high-stakes approach to its HDD business recently paid off on a specialty project in Los Banos, California. This was the first of a few bores that involved installing power to a warehouse being converted to a manufacturing facility.

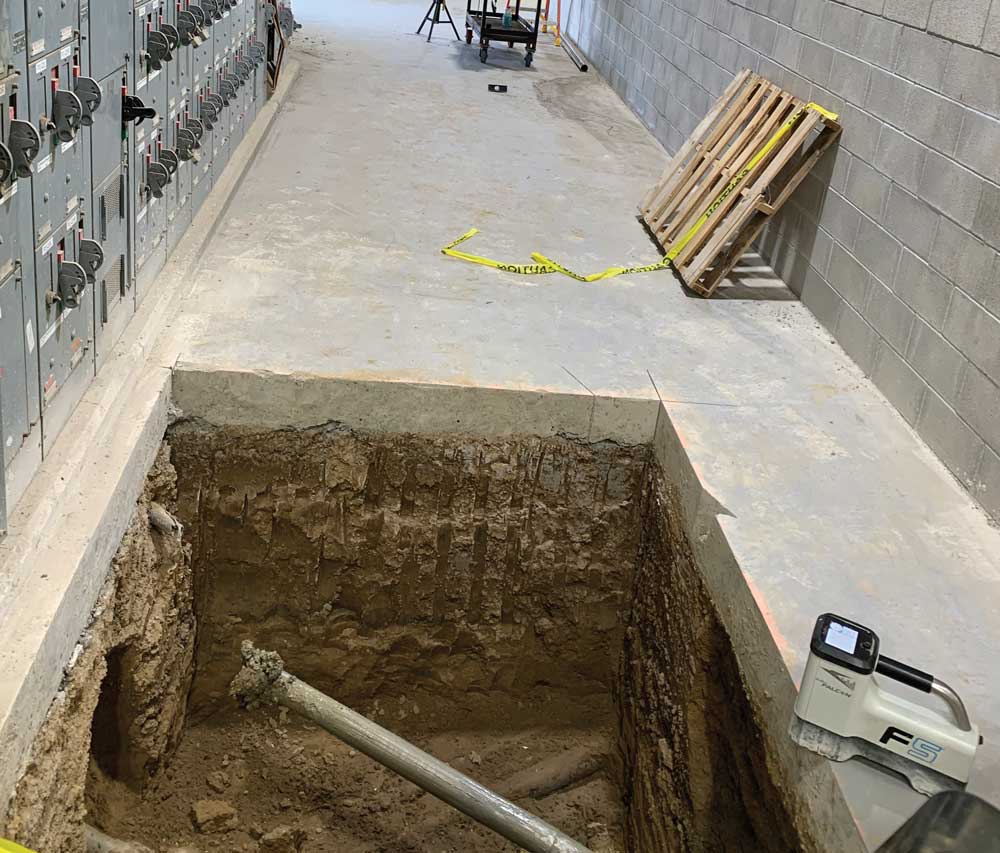

The setup for the 220-ft bore was challenging in every possible way — a small target in the middle of a packing plant, drilling under a steel reinforced concrete foundation, a 20-ft elevation change, metal conveyers obstructing the bore path and heavy active interference. UBS knew it had its work cut out for them and was nervous about the complexity of the job. Where many HDD contractors might have passed on the project, UBS chose to call upon the expertise of Digital Control Inc. (DCI), backed by its California territory manager, Jesus Alderete.

Alderete traveled to Los Banos to meet with UBS owner Sanj Mann and locator Darren Bell. UBS had purchased a Sub-k Rebar Transmitter for the project and given the large elevation difference, Alderete brought with him the TeraTrak R1, DCI’s continuous terrain mapping device.

The project began by using the Falcon F5 to scan the bore path for active interference. As the team approached the mid-point of the bore, they encountered very high levels of active interference and Alderete provided hands-on training to walk Bell through the Falcon frequency optimization process. Bell then chose Sub-K band 0.7 kHz for the passive interference and band 7 kHz to battle the active interference.

Having the right frequencies for the job was only half the battle, the crew also needed a plan; cue the TeraTrak R1. The R1 was used to map the bore with continuous elevation, grade change, obstacles, and way points. The R1 mobile app quickly generated a rod-by-rod plan and rig setback for the crew to get started. Above Ground Range (AGR) testing confirmed they had the right transmitter frequency and power to get this job done.

The crew began the bore at the bottom of a steep incline with a target depth of 21 ft at the top. They hit that target but still faced many obstacles ahead. After clearing the hill, the crew navigated the drill head through a 75-ft section of metal conveyers that made it difficult to get accurate locate points. By utilizing remote steering for left/right guidance, the crew successfully crossed these obstacles where walk over locating was not possible. Then the real challenges began.

A 10-ft drop from the exterior plant wall to ground-level made depth accuracy a huge concern. With the exit-pit only 100 ft away there was no room for error. Anyone who knows HDD locating knows that passive interference can give greater than expected depth readings, a recipe for disaster when precise depth is imperative. The drill operator used the Repeating- Roll-Sequence (RRS) to change bands from the higher-frequency band 7kHz to the lower rebar-frequency band 0.7kHz. Running the Sub-K rebar-band, the crew proceeded confidently and was able to verify their locates and depth readings were not affected by passive interference.

The last 100 ft of the shot were completed without interruption. Consistent locate points, signal strength, and depth readings gave the crew confidence in their data and allowed Bell to hit the small exit pit spot-on at his target 30-in. depth. His excitement relief was clear.

“It is always helpful to evaluate the site properly, understand the anticipated risk and use the right tool to mitigate the risks. Also, better to discuss with a locating expert in advance to find the best solution,” Bell said.

A hole in one in golf is a rare feat, a hole in one in HDD locating is a daily expectation. While some contractors struggle, the fact is technology continues to rapidly advance in the field of HDD locating. DigiTrak Falcon is the foundational technology that enables success on the toughest and most complex jobs. Uptime, capabilities, and range are better now than ever before. And as is often the case, having the proper tools means the difference between success and failure.

Anthony Burasco is media director at Digital Control Inc.