Building a Better Siphon Using Design Drops in Upstream Siphon Manholes

Inverted sewer siphons carry wastewater underneath rivers, channels and roadways. The wastewater completely fills the pipe and flows under pressure and at higher velocities than the gravity sewer that feeds it. This higher pressure and velocity leads some to believe that siphons are self-cleaning.

They are not!

The Problem

Many large solids find their way into sewer systems and settle into the inverts of siphons. Our National Plant Services Inc. (NPS) crews have removed rocks, large chunks of concrete and vitrified clay pipe (VCP) pipe, 4×4 lumber, PVC sprinkler pipe, rebar, plastic bottles, rag balls and even sofa cushions from the inverts of siphons. This settled debris traps fecal waste as well, resulting in microbial growth and the production of H2S gas that migrates out of the siphon invert, and often causes concrete corrosion to the upstream and downstream siphon manholes.

Typical Maintenance Methods:

In-Service Flushing

Some cities and agencies perform in-service flushing of siphons on either a monthly, quarterly, semi-annual or annual basis. However, most siphons are never cleaned or flushed until a condition assessment is desired, or if there is an emergency failure or SSO. In-service flushing of small diameter siphons is relatively successful in helping move fine deposits and rags through the siphons.

However, large diameter and longer-length siphons collect much more debris than small diameter siphons, and they are difficult to flush while in-service due to the large quantity of water and debris inside of them.

In a recent bypassed siphon cleaning and inspection project completed by NPS, two single barrel siphons that were approximately 400 lf in length were found to have significant debris quantities: 34 cubic yards was removed from the 42-in. diameter siphon, and 36 cubic yards of material was removed from the 39-in. diameter siphon. NPS crews also removed a giant rag and debris ball from the 42-in. barrel that was taking up 75 percent of the siphon’s interior diameter.

However, in-service flushing is helpful in removing rags from inside of large diameter siphons. Photos to the left are images from a 24-in. diameter siphon that NPS crews flushed while in service. The sonar signal was still blocked at the end of the first day, even after multiple passes with the jetter/vacuum nozzle. However, by the second day of flushing, the sonar scans were visible and the siphon walls and debris levels could be assessed. In-service flushing is an important first step before sonar inspections are attempted, whether in small or large diameter siphons, otherwise it may be a wasted effort as rags can cover the sonar device and block any sonar signal.

Dewatering, Cleaning, and Inspection:

The most accurate tool to inspect a siphon is to perform a conventional CCTV inspection. Visual identification is important to assess concrete corrosion, cracking, and other defects. In order to perform this CCTV inspection, the siphon must be removed from service, dewatered, and cleaned. To remove a siphon from service, diversion of all wastewater flow is required to isolate each barrel.

Multi-barrel siphons can generally be cleaned and inspected by using flow-through plugs to divert water from the barrel to be cleaned into the other barrel/s. For single barrel siphons, or where a multi-barrel siphon has flows too high for plugging, a pumped bypass system would need to be set up to bypass wastewater above-ground, around the siphon, in order to clean heavy debris and then inspect. Bypassing of wastewater flow around siphons can be very costly, so mitigation measures to prevent heavy debris build-up from occurring is key.

Better Design Solution: Drop Siphon Manholes

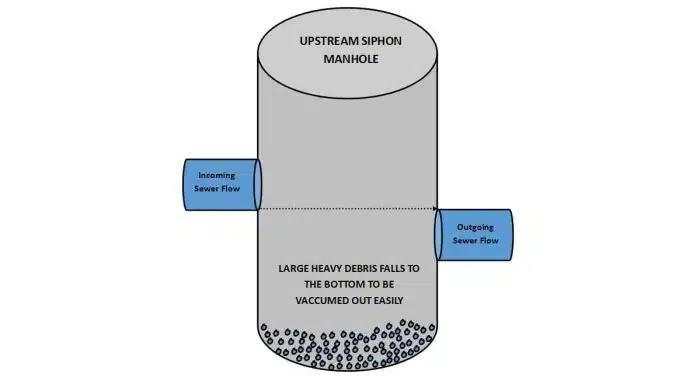

Storm drain systems often contain drops or grit chambers in their manholes, but this feature is seldom implemented in sanitary sewer systems. These drop manholes are designed so that the manhole invert is deeper than the invert of the incoming and outgoing pipes.

This simple manhole design change should be implemented to an upstream manhole leading to sanitary sewer siphons; especially in the case of large diameter siphons, and for siphons that are long in length.

As wastewater flows into the manhole, heavy debris falls to the bottom of the manhole, while the fecal material and rags flow through the manhole and into the siphon. This collection of large material before a siphon will ensure that lighter material will flow easily through the siphon; and that rags don’t bind with large, settled, material to create a blockage in the siphon. It will also reduce H2S gas formation as settled deposit levels will be reduced within the siphon invert.

These drop manholes would then be placed on a regular preventative maintenance schedule where municipal or contract crews can easily vacuum out the debris from the drop manhole. The frequency of cleaning will depend, and can be adjusted over time, based on the amount of debris that enters the manhole drop, and as-needed to reduce the potential for H2S gas formation in the manhole.

The manhole design depth will depend on the preventative maintenance frequency that an agency or city will set to vacuum the debris from the manholes, and should be considered during the design phase.

This simple manhole design change will go a long way to help reduce debris levels and prevent blockages inside our siphons, significantly reduce siphon maintenance and cleaning costs, help prevent SSOs and help reduce H2S gas levels inside siphons that result in microbial-induced corrosion to manholes and piping. We hope to see more drop siphon manholes in future sewer system designs.

Michelle Beason, P.E., is a regional manager at National Plant Services Inc., a Carylon Company.