Potable Water Tank Relining in Telluride, Colorado

August 24, 2017

Located about 500 ft up , an old dirt cross back mining road above the picturesque town of Telluride, Colorado, at roughly 9,250 ft above sea levels, sit two 260,000-gallon potable water tanks. The tanks were built between 1920 and 1930 and it was thought that the tanks were made of concrete, but after the west tank rehabilitation project started it was found that at least the upper 4 ft of the tank was constructed with stacked stone.

Located about 500 ft up , an old dirt cross back mining road above the picturesque town of Telluride, Colorado, at roughly 9,250 ft above sea levels, sit two 260,000-gallon potable water tanks. The tanks were built between 1920 and 1930 and it was thought that the tanks were made of concrete, but after the west tank rehabilitation project started it was found that at least the upper 4 ft of the tank was constructed with stacked stone.At some point in the west tank’s life it had been coated with gunite products to the average thickness of 3 in. This was most likely done to provide structural stability and water tightness. Unfortunately, the west tank continued to leak excessively and in the 1970s a hypalon liner was installed.

RELATED: Raven Lining Systems Earns USDA Certified Biobased Product Certification, Label

The hypalon liner worked well for 40-plus years, with only small repairs needed but the cost of such repairs grew to the point that it was no longer cost-effective to maintain the liner. Also, it was found that more than 2.1 million gallons of water was still being lost annually. A rough tank replacement cost estimate was done and it was found that it would be more than $4 million to build new tanks on the same location. This was not just due to the cost of the tanks but also to the fact that the road leading up to them would have to be totally redone to make it usable by heavy equipment. The town would also be without half of its water supply during demolition and reconstruction. It was decided in 2015 after an inspection of the tank that the old liner needed to be removed, the tank repaired and a new coating system installed.

Relining Solution

In October 2016, a contract was issued to John LaDuke and Global Linings out of Gunnison, Colorado, to rehabilitate the western tank using products manufactured by Raven Lining Systems, Broken Arrow, Oklahoma.

Once the old liner had been removed, large portions of the gunite fell off the walls and hollow stops were found. All the loose gunite was removed, exposing the stacked stone beneath and most of the mortar between the stones was lost. A thorough cleaning was done with water and then cement repairs of the structure commenced.

Large holes at the end of the roof support beams had to be filled along two old pipe inlet and out lets along with all other surface defects using a polymer modified cement.

Once all the damaged areas had been repaired and the tank was cleaned a water born penetrating epoxy primer was applied in two coats to seal and strengthen the repairs and the structures surface.

After the water-born, epoxy-primer cured but within the recoat window, a coat of a 100 percent solids epoxy primer was applied. This was done to further seal the structure and also provide enhanced adhesion of the first coat of a hybrid polyurethane coating to the substrate.

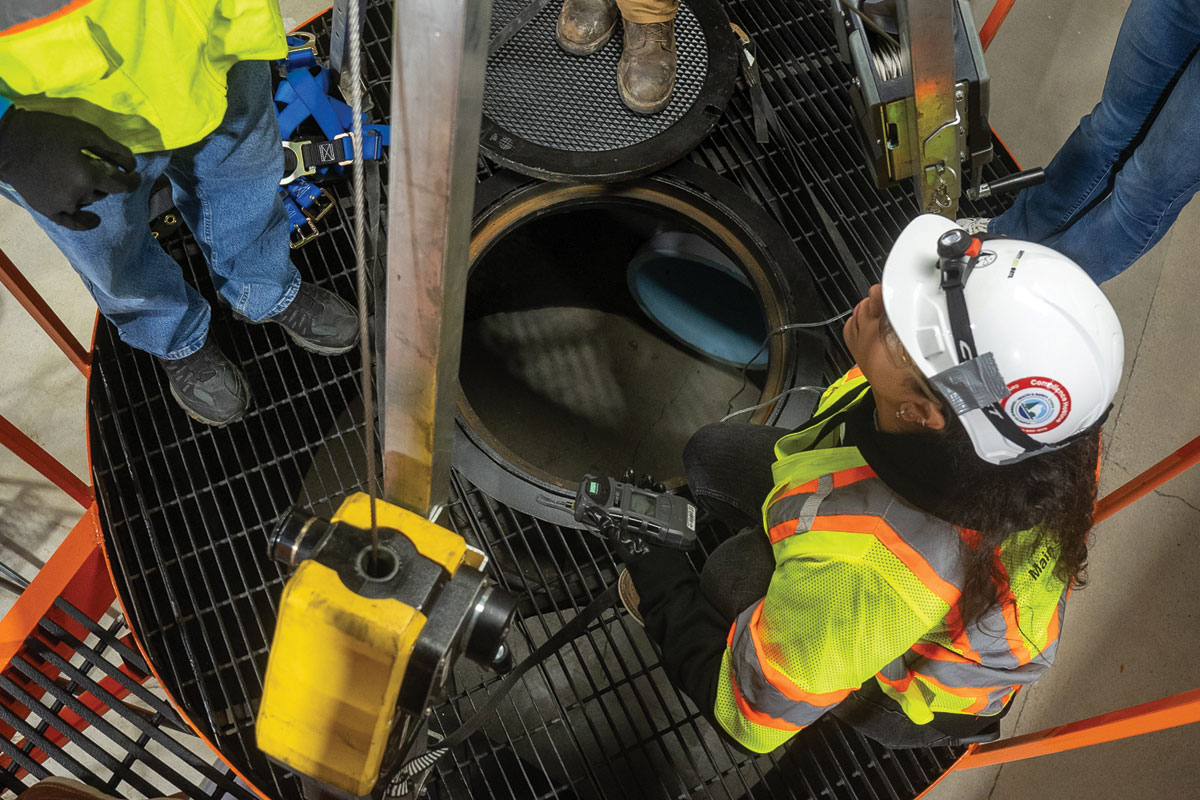

Both the first and second hybrid polyurethane products rapid cure rates required them to be spray-applied using plural component equipment and air purge impingement spray guns. The application of the first hybrid polyurethane coating on the walls provide an adhered water tight liner and acts as an adhesive for geotextile fabric that was inlayed into the liner while it was still in the wet/tacky state within the curing process. The outside of the tank’s was also cleaned and prepared then coated with the same product to seal it from leaking dirty water and debris into the tank as well as acting as a barrier coating for corrosion prevention.

With the walls lined and fabric inlayed, the entire interior of the tank was coated with more than 125mils of a NSF61 potable water approved flexible polyurethane lining. The application is a semi adhered water tight flexible liner. The second lining product was also applied over the roofs support beams and legs to provide a further barrier coat and protect them from corrosion.

Town of Telluride engineer Drew Lloyd stated once the project was complete that the town was extremely happy with the application of the lining products and workmanship under difficult access conditions by the contractor along with the performance of the lining system to date.

Matt Wierzchowski is regional technical sales manager – Rocky Mountain Region and Ryan Bauman is senior technical service specialist with Raven Lining Systems.