Improving Cleaning Efficiency at City of Eagan

The City of Eagan is located just south of Minneapolis and Saint Paul along the southern bank of the Minnesota River. In the last 50 years, Eagan transitioned from a small farming community to more than 67,000 residents working for various industries today.

Just a few years ago, the wastewater department at the City of Eagan performed sewer maintenance like most utilities across the country. Sewer lines were cleaned based on an assigned time interval. In the City of Eagan’s case, crews cleaned each sewer line in the City’s 280-mile system over a three-year cycle – or approximately 90 miles per year.

RELATED: Cutting Capital Costs with Pipeline Condition Assessment Tools

While the City’s time-based program effectively prevented sanitary sewer overflows, officials suspected that significant resources were deployed to clean pipes that did not need maintenance using this time -based strategy. While this is an all too familiar problem in the wastewater industry, it is especially relevant to a younger community like Eagan with infrastructure that is only 40 to 50 years old.

“When I was one of the operators sitting in the truck, I had a problem with cleaning everything because it can feel like we’re cleaning for no reason,” describes Brent Massmann, utilities operations supervisors for the City of Eagan. “Nothing is coming out and it feels like we’re just going through the motion.” Until recently using a time-based method was the only practical option available, because acquiring information regarding a pipe’s blockage condition remained cost prohibitive and time intensive.

Using Sound to Determine Cleaning Need

In 2018, the City of Eagan first heard about acoustic inspection technology and considered the benefits of implementing a screening tool. “I’m always keen on emerging technologies,” says Massmann. “The biggest thing on my mind was gaining efficiencies.” He believed that if his team could quickly understand the condition of their system, they could reduce unnecessary cleaning and free up those resources for other needed activities. Using pipe blockage condition data, rather than time, to trigger cleaning could substantially improve the team’s efficiency in an already successful program.

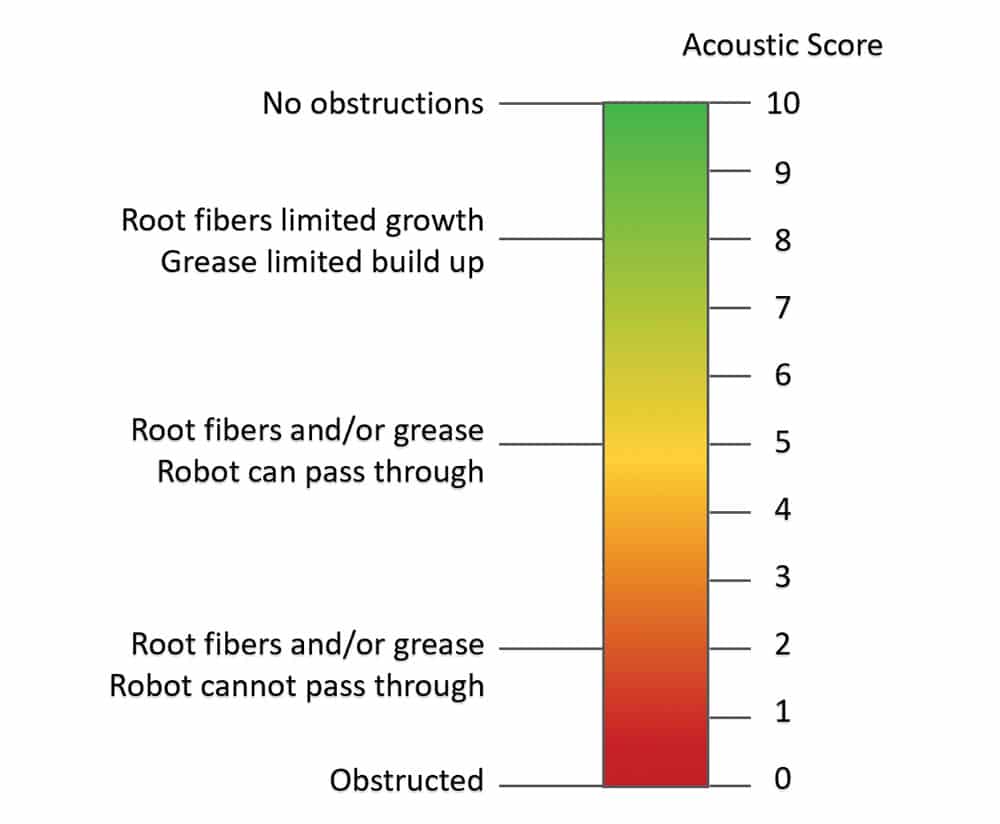

The Sewer Line Rapid Assessment Tool, or SL-RAT, is designed to provide the condition assessment data necessary to guide decision making. The SL-RAT, manufactured by InfoSense Inc., uses transmissive acoustics to rapidly screen small diameter sewer lines for blockages. The SL-RAT is comprised of two portable components that sit on top of adjacent manholes. The transmitter unit creates a series of audible tones, while the receiver unit listens for those known sounds. A blockage assessment is provided in three minutes or less, allowing operators to gather inspection data very rapidly. The scores range from zero to ten and have correlating condition assessments: BLOCK (score of 0), POOR (score of 1-3), FAIR (score of 4-6), and GOOD (score of 7-10).

Proving the Value

In early 2018, the City of Eagan created a pilot program to put acoustic inspection technology to the test. Contractors familiar with the SL-RAT helped screen 6,000 lf, which was follow up with CCTV inspections. Eagan’s team compared the acoustic assessment scores with CCTV visuals and established expectations for the range of scores. This process verified that acoustic inspections could provide the data necessary to transition to a condition-based maintenance protocol.

RELATED: Santa Barbara Incorporates Acoustics to Prioritize Sewer Maintenance

“The biggest motivator for me once I knew the technology was viable, was to be able to be more efficient with the time that we have and use it where we need to,” says Massmann. Within months, Eagan developed and implemented their own acoustic inspection program, which was initiated during the summer 2018.

Moving from Time Based to Condition Based Cleaning

The focus of Eagan’s acoustic inspection program is to reduce unnecessary cleaning by using screening data to understand the condition of their system. Every summer since 2018, the City of Eagan has hired seasonal staff to acoustically inspect one-third of their 280-mile system. On average, a crew inspects 15,000 ft/day, allowing them to complete the annual inspection goal within three-months. “We are prescreening for next year’s maintenance and deciding what needs to be cleaned one year in advance,” describes Massmann. “If they get a zero, or BLOCK result, we go and look at it right away.”

Eagan’s approach is to clean any segments with acoustic assessments of BLOCK, POOR or FAIR (scores 0-6), which turns out to be only one-third of their system. The other two-thirds of their system are determined to be in GOOD condition (scores 7-10) and will be additionally inspected with CCTV as needed.

In addition, Eagan’s robust data management process and GIS team help to streamline the process. The field crew uses the ESRI Collector App to note acoustic scores in the field. Based on the score, appropriate follow up actions are triggered. The inspection data is also uploaded to InfoSense’s cloud-based Sewer Line Data OrGanizer (SL-DOG) for archiving. In short, efficiency is ingrained at every step along the way.

RELATED: How Oklahoma’s Primary Municipal Insurer Is Helping Utilities Prevent SSOs

The Benefits of Changing

By using acoustic technology, Eagan has reduced cleaning by two-thirds, or 60 miles, annually. Although they are cleaning significantly less, their system performance remains just as strong – with very few problems occurring. By identifying areas with need using inspection data, Eagan is ensuring that valuable labor and resources are being used effectively. “After being in the supervisor role, I see the difference now of seeing a half a million-dollar truck going out every day with two operators to clean a line that maybe doesn’t even need to be cleaned – we can use that labor somewhere else,” says Massmann.

The investment in collecting their system’s condition data is worthwhile for the city of Eagan. Reducing unnecessary cleaning has helped to reallocate more than $150,000 and 3,000-plus crew hours annually, even after accounting for acoustic inspections. The reduction in cleaning also saves the city almost a million gallons of water annually.

Massmann has been happy with the results. “The SL-RAT is compact, it’s extremely reliable, it’s robust and it does exactly what it’s supposed to do. We wanted to be more efficient, and the technology is viable for what we’re trying to do.”

Diane Ryu is the product and marketing manager at InfoSense.