Combined Benefits: Combo Sewer Cleaner Recycling Systems Save Time, Money and Water and Increase Productivity

October 13, 2016

Conservation, Green, Eco-friendly, Sustainable and Recyclable are not only buzzwords splashed across print and digital media platforms; the words also express what many people across North American find truly important today. These are words that do not come to mind when discussing construction equipment — specifically sewer cleaning combo trucks.If the manufacturers of these mighty machines have anything to say about it that is going to change. In the last year Vactor, Vacall and Super Products all launched combo trucks that feature onboard recycling system options. These units not only promise to reduce costs but also increase productivity.

RELATED: Super Products Adds Regional Sales Managers, Business Development Manager

“I don’t know why you wouldn’t want to use the recycler. Depending on what truck you buy, the normal capacity of say a 1,500-gal water tank and you jet at 80 gpm, you won’t be out there jetting very long before you need to refill,” says Bill Petrole, vice president of Vacall products for Gradall Industries. “Recycling recoups the water you are jetting including any water that is in the sewer line and you can stay out all-day long without having to stop.”

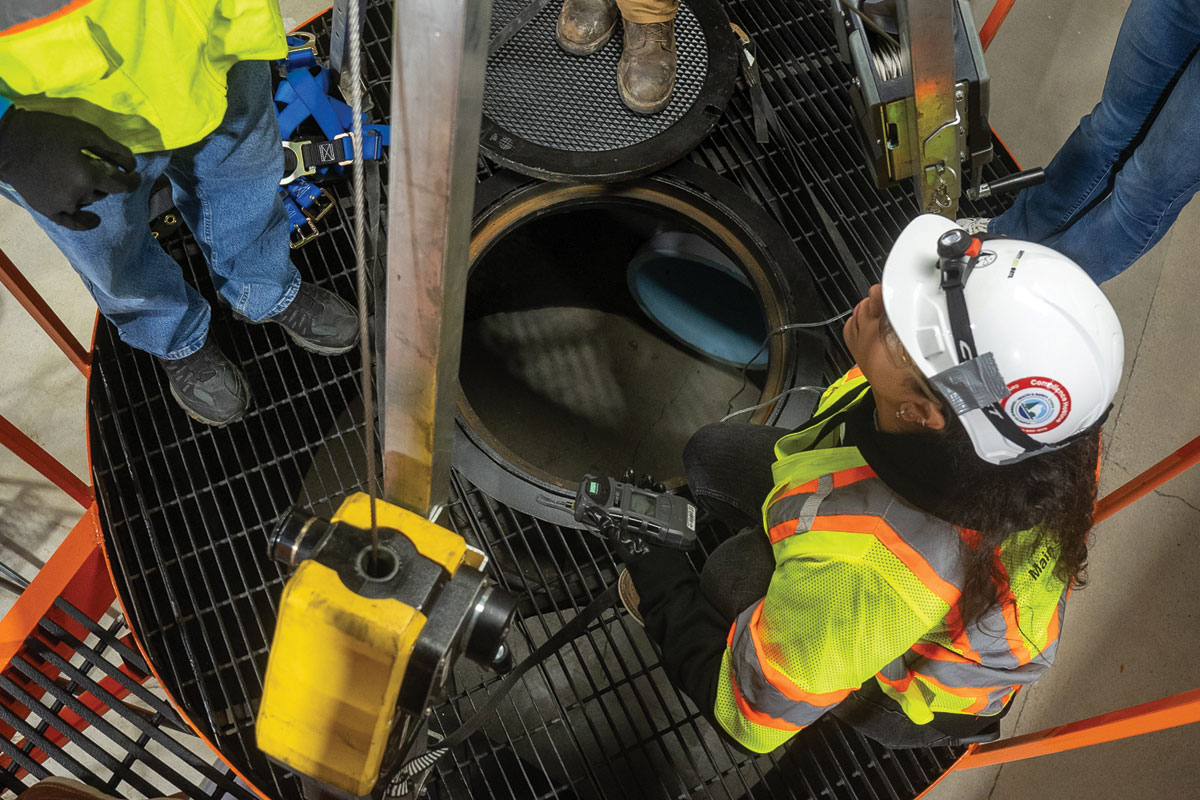

Super Products, Vactor and Vacall all showcased wastwater recycling option for their respective combination sewer cleaners at WWETT 2016.

Vacall debuted its water recycling option — available on its AllJetVac trucks — at the 2016 Water & Wastewater Equipment, Treatment & Transport Show (WWETT) in February. Also unveiling a wastewater recycling system at WWETT was Super Products with its Camel 1200 truck. Vactor unveiled its option — available for the 2100 Plus series combination sewer cleaners — at WEFTEC 2015 in Chicago.

“Contractors, municipalities and utility companies can all see great benefits using the Vactor water recycling system,” says David Brockman, associate product manager, Vactor Mfg. “These customers are all facing many of the same problems: reducing the impact on the environment and extending productivity with fewer resources. Vactor’s water recycling system provides a substantial step in the right direction.”

RELATED: Vactor Celebrates 101 Years in Business

Recycling system benefits, according to Brockman, include:

• Promoting sustainability and reducing or eliminating the use of clean water.

• Water is becoming more valuable.

• Reduced overflows.

• Hiring and finding personnel is becoming increasingly more difficult.

• Improved safety.

Both Vactor and Vacall estimate that running without the recycler, crews have to stop every 20 minutes to refill a 1,500-gal tank and the refilling process can take anywhere from 30 minutes to two hours depending on the location of a fresh water source.

Water Conservation

Combo sewer cleaners are not a new piece of equipment in the industry so why is the recycling option gaining steam now?

“Water recycling is being offered by more manufacturers than ever before,” Brockman says. “This is driven by the need to conserve resources while cleaning more lines to prevent overflows. Technology improvements have made water recycling more efficient and more affordable.”

According to Petrole, Vacall’s projections show the AllJetVac with the Recycler system can save an average of 5.7 million gals of water per year. The calculation is based on typical municipal usage characteristic for the AllJetVac combination sewer cleaners of using 80 gpm of water, six hours per day, 40-weeks a year.

Petrole estimates that the combination cleaner user, — not running a recycling system — spends about $70 a day for 5,000 gals of water per day. What many people do not consider, or have not until recently, is that it costs about $5 to treat 100 gal of water. Someone has to pay for that, Petrole says.

“It’s green that works. We figure a municipality can save 5 million gals a year. That is water that doesn’t have to be treated or water that doesn’t have to get dirty,” Petrole says. “Every municipality that has environmental concerns should purchase someone’s recycler just for the betterment of the Earth. No one can argue with that.”

Both the Vacall and Vactor options feature a five-stage cleaning process and the water is filtered to 100-microns reducing the likelihood of clogs and damage to the getting equipment. The units are also self-cleaning systems that require little to no maintenance with one exception being grease. Petrole refers to grease as a sewer cleaner’s worst enemy. If working in areas with heavy grease and oil deposits — like adjacent to a restaurant row — the trucks may need to stop to clean the debris bodies or filters.

Increased Productivity

But, since debuting the model in Indianapolis and taking the demo truck on the road, more customers and potential customers for the machine are more interested in the increased productivity.

“Without the need to stop work to replenish the fresh water supply, sewer contractors will experience longer onsite performance. Contractors get paid by the foot of sewer line cleaned,” Brockman says. “With the Vactor water recycling system, productivity is increased by as much as 100 percent, so operators can clean up to twice the number of lines. There is no need to break down equipment on the job in order to drive to an available hydrant to refill the water tank, a process that can happen multiple times in a given work day.”

RELATED: February 2016 Pipe Cleaning Products Showcase

Both Vactor and Vacall estimate that running without the recycler, crews have to stop every 20 minutes to refill a 1,500 gal tank and the refilling process can take anywhere from 30 minutes to two hours depending on the location of a fresh water source.

“At Vactor, we have found that many communities are restricting where trucks can be refilled, which further reduces the cleaning productivity,” Brockman says. “Because refilling is required multiple times a day and this process is all wasted time, fuel, risk, and wear and tear on the vehicle.”

There is one unavoidable caveat Petrole says. It is the debris tank capacity.

“The debris tank can only hold so much. You will fill the debris body with solids,” he says. “In our experience, we can run all day long and only dump once. And if you have a wet line or flowing line, you can vacuum water out of the dirty line, through the debris body and then you recycle the water to the jetter. So you don’t have to stop and get clean water, you can start with dirty water.”

When looking at return on investment, which is especially important to cash strapped municipalities, both Brockman and Petrole estimate their respective recycling options will pay for themselves in six months.

Mike Kezdi is associate editor of Trenchless Technology.