Plan to Attend the 2017 Trenchless Technology Road Show

August 4, 2017

Educational, Networking Opportunities Abound at Three-Day Event

Clearly, British Columbia is interested in trenchless technologies. That was made evident in 2015 as the inaugural Trenchless Technology Road Show not only featured a sold-out exhibit hall but also boasted more than 250 attendees. The question then was not a matter of if, but when the organisers — the Centre for Advancement of Trenchless Technologies (CATT), Benjamin Media Inc. and the North American Society for Trenchless Technology’s British Columbia Chapter (NASTT-BC) – would bring the show Road Show west again.

Clearly, British Columbia is interested in trenchless technologies. That was made evident in 2015 as the inaugural Trenchless Technology Road Show not only featured a sold-out exhibit hall but also boasted more than 250 attendees. The question then was not a matter of if, but when the organisers — the Centre for Advancement of Trenchless Technologies (CATT), Benjamin Media Inc. and the North American Society for Trenchless Technology’s British Columbia Chapter (NASTT-BC) – would bring the show Road Show west again.RELATED: NASTT-BC Is an Integral Part of Canada’s Trenchless Growth

Book your hotel, pack your bags and be sure to register because the 2017 Trenchless Technology Road Show will stop at the Sheraton Vancouver Airport Hotel in Richmond, British Columbia, Sept. 25-27 to provide a platform to educate municipal, engineering and contractor personnel on the benefits of trenchless methods.

The Trenchless Technology Road Show consists of two full days of technical presentations and exhibits bringing you the latest advancements in trenchless technology. For those wanting to pack more trenchless education into the trip – and based on attendee feedback at previous Road Shows – organisers have planned five trenchless workshops.

The three full-day (“Trenchless Technologies 101,” “Watermain Renovation Using Structural, Semi-Structural and Non-Structural Lining Systems” and “Horizontal Directional Drilling: Design to Construction”) and the two half-day workshops (“Trenchless Carbon Savings & Credits” and “Planning Trenchless with Subsurface Utility Engineering”) take place Sept. 25. The courses are led by the industry’s leading experts and of note is the SUE half-day course features Jim Anspach, co-creator of the ASCE 38-02.

The main event will feature 11 sessions, with a total of 58 technical presentations, covering among other things, asset management, pipelines condition assessment, subsurface utility engineering, trenchless technologies and the renewal of underground pipelines and utility ducts.

EXHIBIT HALL

Due to popularity of the show and further highlighting the growth potential of the trenchless market in British Columbia, the exhibit hall quickly sold out with nearly 50 exhibitors. Contact Brittany Cline, at bcline@benjaminmedia.com to be placed on the exhibitor waiting list. In addition to exhibiting at the show there are outdoor demos available. Contact Cline if you are interested in hosting an outdoor demo. Demos are scheduled to take place following lunch before the technical sessions resume.

WAYS TO SAVE

Save $100 if you register by Sept. 20. Registration for each of the full-day pre-event workshops is $400 for CATT and NASTT members and $500 for non-members and $300 and $400 for half-day courses. Registration for the Road Show is $550 per day or $650 for both days for member and $650 per day or $750 for both days for non-members. An exhibit hall only pass is available for $50. Visit trenchlessroadshow.ca to register.

KEYNOTE SPEAKER

Following lunch on Sept. 27, Dr. Mark Knight, executive director of CATT, will offer a State of Canada’s Trenchless Industry report followed by the keynote speech by Mike Sullivan, executive director of the Canadian Common Ground Alliance (CCGA).

In addition to his work with the CCGA, Sullivan is president of Alberta One-Call Corp. and an advocate for spreading the safe digging message across Canada. His damage prevention experience stems from a 25-year career with Canada’s federal transmission pipeline regulator, the National Energy Board, Alliance Pipeline Ltd., HMA Land Services Ltd., Alberta One-Call and the CCGA.

RELATED: For the Common Good: Spreading the Safe Digging Message Across Canada

As executive director of the CCGA, and a member of the Common Ground Alliance’s Board of Directors, Sullivan represents the collective damage prevention voice for Canada.

Sullivan grew up in Montréal, Québec where he was educated in English and French, and has travelled extensively across Canada; learning the intricacies of each province’s individual damage prevention evolution and journey. In 2014, the Common Ground Alliance in the United States presented Sullivan with the Jim Barron Award, which is given to an individual has shown true dedication to efforts enhancing underground damage prevention. To date, Sullivan is the only Canadian recipient of this award.

For more information on registration, accommodations or sponsorships and demos, visit trenchlessroadshow.ca.

2017 Trenchless Road Show Preview

AKKERMAN

AKKERMAN

Akkerman guided boring contractors are tackling up to 42-inch steel casing installations in rock with the Rock Drill Adapter (RDA), the Guide Rod Swivel (GRS) 50 and the Rock Boring Unit (RBU). The RDA provides a means for an accurate pilot tube installation in rock formations up to 18,000 psi using TriHawk Drill Bits. To follow the pilot tubes, the GRS-50 family matches common steel casing diameters and functions to keep pilot tubes stationary while the assembly’s cutter head, equipped with durable carbide gage cutter bit tooling excavates difficult ground while able to withstand continuous thrust loads up to fifty tons. In the most challenging rock conditions, our RBUs are engineered for rock boring with aggressive disc cutters to excavate up to 18,000 psi UCS geology when following pilot tubes or up to 25,000 psi UCS geology for unguided rock boring with the full-face disc cutter insert. Learn more at akkerman.com.

APEX

APEX

Apex has been a leader in solids control development for more than 20 years. Our experience in particulate separation across several industries and applications has allowed us to identify efficiencies in centrifuge technology, and we pass those efficiencies on to our customers. We also have a full line of surface rentals, including remote on-site accommodation, power generation, matting, transportation, fluid storage, pumping solutions and waste water storage and treatment. With 10 full service branches from Ft. St. John, British Columbia to Estevan, Saskatchewan, and two more in the United States in North Dakota and Ohio, we are close enough to constantly maintain our equipment, keeping down time and transportation costs to a minimum. Apex is proud to be involved with CATT, and we invite you to experience the service from Apex on your next trenchless project.

ASI MARINE

ASI MARINE

ASI Marine provides industries and governments worldwide with leading-edge underwater services focused on the assessment, maintenance, rehabilitation, and construction of underwater infrastructure and environments. ASI Marine specializes in underwater remotely operated vehicle (ROV) inspections, commercial diving, marine geophysical surveys, and underwater mapping. To learn more, call 905-641-094, email info@asi-group.com, visit asi-group.com or stop by our table at the Trenchless Technology Road Show.

CT SPEC

CT SPEC

CTSpec Web Viewer is a Web-based application that allows users to access all your CTSpec — Cloud secured inspection data. As your inspection data is transferred seamlessly by your contractors onto the Cloud, the data becomes available through the Web Viewer user-friendly interface to all granted users. Search — Once users get access to Web Viewer, they are allowed to search for pipes, manholes or laterals using search criteria such as their asset number, road location, inspection specific or span dates, or by their structural or operational grades. View — Once found, the inspections are listed. Web Viewer allows users to pick specific inspection and view related videos, pictures and observations as well as consulting the inspection details. Share — If required, Web Viewer will allow you to share a specific inspection with someone else without the need for that person to log into Web Viewer. For more information, call 888-965-8987 or visit ctspec.com.

CUES CANADA INC.

CUES CANADA INC.

The SPiDER Scanner is the first wireless and color manhole inspection technology in a lightweight and compact form factor. The SPiDER is a scanner which can calculate its position in the manhole shaft by using its sensor data to measure its incremental motion instead of the payout cable. SPIDER weighs less than 30 lbs. and can be hand carried to easements or other previously difficult to access sites. This wireless portability is possible because the processing computer and battery supply are built into the scanner. SPIDER collects millions of three-dimensional (3D) measurements during each manhole inspection so the manhole can be measured to less than 5 mm accuracy. The point cloud can be used to evaluate the structural changes in a manhole before and after rehab. The SPiDER also provides live-video stream and recorded MPG video making it an ideal wireless tool for Infiltration and Inflow studies.

DIGITAL CONTROL INC.

DIGITAL CONTROL INC.

Since the first utility was installed using horizontal directional drilling, two things have plagued walk-over locating systems; active interference and passive interference. Digital Control Inc. (DCI) has developed solutions for both. Active interference has been virtually eliminated when using DCI’s DigiTrak Falcon system by allowing locators to select two optimal frequency bands based on each drill site’s individual active interference profile. DigiTrak Falcon F5’s passive interference solution offers dozens of frequencies between 0.3 – 0.8 kHz. (300 to 800 Hertz). DCI has known that lower frequencies perform better in passive interference environments but until now, have not performed well due to limited depth ranges. DCI’s approach is to use the proven higher frequencies for sending transmitter data and the sub kHz frequencies for depth and direction. These ultra-low frequencies, coupled with DigiTrak Falcon F5’s ability to filter out active interference, permits successful pilot shots in both passive and active interference environments.

DIRECT HORIZONTAL DRILLING

DIRECT HORIZONTAL DRILLING

Direct Horizontal Drilling is Canada’s premier horizontal directional drilling contractor with an extensive fleet of drilling rigs, an excellent team of knowledgeable and dependable people and the most successful history of river crossings in Canada. Direct Horizontal operates from coast to coast, headquartered out of Edmonton, Alberta and field locations throughout Western Canada. Direct Horizontal equipment and crews have extensive experience operating in extreme weather conditions. For more information visit us at the Trenchless Technology Road Show.

ELECTRO SCAN INC.

Electro Scan has become the new standard for testing of trenchless rehabilitation projects. Designed to certify cured-in-place pipe (CIPP), fiberglass reinforced pipe (FRP), high-density polyethylene pipe (HDPE), spiral wound pipe (SRP), and point repairs, including short liners, Electro Scanning Inspection locates and quantifies all leaks from accidental cuts, bad service reconnections, overcooked liners, poorly cured pipes, and faulty resins that leak – typically missed by CCTV. Non-conductive materials prevent electricity from passing through, or along, the wall of a pipe. Electrical current should never be able to “leak” from inside a pipe unless there is an opening in the pipe wall. A defect in the pipe that leaks water will also leak electrical current. The larger the defect, the greater the electric current flow as described in ASTM F2550. Add Electro Scan equipment to an existing CCTV truck or contact Electro Scan Inc. at 916-779-0660, email info@electroscan.com or visit us at Booth 107 at the Trenchless Technology Road Show.

LMK TECHNOLOGIES

LMK TECHNOLOGIES

LMK’s T-Liner is a one-piece homogenous main and lateral CIPP connection liner that is ASTM F2561 compliant. T-Liner has a uniform wall thickness and can be installed with either polyester or epoxy resin. Both the mainline and lateral sections are formed as a structural cylinder that renews 18-in. and 360-degrees of the mainline and extends up the lateral pipe as one continuous lining. T-Liner with Insignia compression gasket-sealing technology provides a verifiable non-leaking system. These compression gaskets are embedded between the host pipe and the T-Liner and are compatible with all pipe types including polyethylene. A permanent lateral identification indicia is placed on the mainline lining which includes the building address and other pertinent information regarding the raw materials and other pertinent manufacturing details. Call 815-640-9302 or visit lmktechnologies.com/t-liner for more information.

LOGAN CLAY PRODUCTS

LOGAN CLAY PRODUCTS

No-Dig pipe by Logan Clay Products is Vitrified Clay Jacking Pipe. No-Dig pipe features unmatched axial strength (to withstand jacking forces), precision machined joints, and is totally corrosion resistant. No-Dig is predominately used with the pilot tube method, along with microtunnelling, and sliplining throughout the United States and Canada. The continuing growth of the pilot tube method is built on utilizing No-Dig pipe to provide a highly accurate and economical trenchless installation. The pilot tube method and No-Dig pipe have been used extensively to install long lasting sewers in challenging conditions where open cut is not an economical solution and in areas where disruption to the community or the environment needs to be kept to a minimum. Using the pilot tube method and No-Dig pipe, installations at greater depths are practical, frequently reducing or eliminating the need for extra lift stations. For more information, contact Logan Clay Products at 800-848-2141, email info@no-dig-pipe.com or visit no-digpipe.com.

MILLIKEN INFRASTRUCTURE

MILLIKEN INFRASTRUCTURE

Milliken Infrastructure’s GeoSpray system is a high-performance fiber reinforced geopolymer mortar specifically formulated and engineered for rehabilitating pipes and culverts. The GeoSpray system’s fast application process enables the rapid creation of a new structural pipe inside an old pipe in need of repair. The application process requires no digging, which virtually eliminates construction related traffic delays. The result is improved performance and strength, and lower total installed costs than alternative methods, including SPR, CIPP and sliplining. For more info, visit infrastructure.milliken.com.

PIPELINE INSPECTION TECHNOLOGY ASSOCIATES

PIPELINE INSPECTION TECHNOLOGY ASSOCIATES

Pipeline Integrity Technology Associates (PITA) was established to position pipeline infrastructure technology strategically to owners and operators utilizing knowledge and technology for critical pipeline infrastructure assets. PITA became a specialty consultant focused on the large diameter water and wastewater pipeline market with robotic inspection, repair and monitoring technologies for condition based asset management. Working with contractors on site over these years has enabled PITA to become more of a practical consultant with the abilities to draw from vast experience with emerging and proven technologies to ensure the right technology is used for the right applications and a fair price. For more information, visit pipelineintegritytechnology.com, email gord@pipelineintegritytechnology.com or visit us at the Trenchless Technology Road Show in British Columbia.

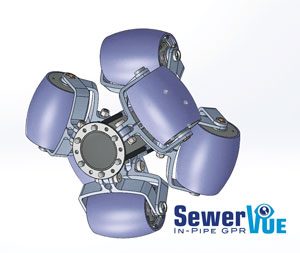

SEWERVUE TECHNOLOGY CORP.

Pipe penetrating radar is a condition assessment technique that that is currently being used around the world to map the remaining wall thickness and detect voids in non-ferrous sanitary sewer pipes. Recognizing the challenges municipalities are having with their asbestos cement pipes, SewerVUE Technology Corp. is adapting this technology to detect delamination and quantify deterioration in asbestos cement water mains. Send us an email at inquiry@sewervue.com to learn more about our new ACPS (Asbestos Cement Pipe Scanner) and how SewerVUE is revolutionizing condition assessment.

SOURCE ONE ENVIRONMENTAL

SOURCE ONE ENVIRONMENTAL

In 2016, a national railway in Canada partnered with Source One Environmental (S1E) and a railway-certified contractor to repair culvert pipe with PipePatch, a trenchless point repair system. The culverts were badly damaged and could have resulted in catastrophic disaster. The locale of the culverts far below the tracks made excavating all but impossible. The team at S1E went to Northern Ontario and trained not only the railway workers but also a contracting company to complete the repairs. The first day two 36-in. concrete culverts were repaired saving the railway many dollars and man hours on the job. In the same week, the contracting company repaired four more culverts ranging from 36- to 48-in. Since this time the railway company has instituted an annual maintenance program using the PipePatch Pillow system, and S1E has recently designed the Pillow Patch system for culvert pipe up to 72-in. diameter.

THE TUNNELING COMPANY

THE TUNNELING COMPANY

The Tunneling Company (formerly Kamloops Augering and Boring Ltd.) has provided comprehensive services to the underground trenchless industry since 1976. Based in Kamloops, British Columbia, we represent multiple generations of Canadian construction knowledge. Our expertise extends to the following areas: horizontal directional boring, augering, pneumatic pipe ramming, pipe bursting, horizontal trenchless consulting, and much more. As the newest member of The Crossing Group, The Tunneling Company has a reputation for making impossible projects possible. Our abilities have been proven time and time again in the most demanding environments on the planet – from the Canadian oil sands to the rugged terrain of Northern British Columbia to dense metropolitan areas throughout Canada and the Pacific Northwest. Reducing the impact development has on the environment and the community, while maintaining the highest standards of safety, guides us in all we do.

TRY TEK

TRY TEK

Since 1985, TRY TEK Machine Works, Inc. has been a leading manufacturer and worldwide supplier of quality equipment for the Trenchless Pipe Rehabilitation Industry. We manufacture cutters that are used for reinstating laterals in relined pipe as small as 80 mm and up to 457 mm pipe. We also manufacture CIPP liner inversion units for liner from 150 mm to 457 mm. Our air routers are not only used on our equipment, but are compatible with competing equipment. TRY TEK equipment is in use around the world in the sanitary sewer, storm, water and natural gas pipe rehabilitation industry. We are located in a 65,000-sq-ft facility in York County, Pennsylvania, USA, just an hour north of Baltimore, Maryland. Providing “Over 30 years of product excellence.”