Alberta’s Ministry of Transportation Uses Trenchless Under Highway 2

July 19, 2016

Alberta’s Ministry of Transportation awarded the 2015 Award of Excellence for Construction Innovation to a pilot project that used CentriPipe to rehabilitate 40-year-old twin culverts located 25 km west of Athabasca on Highway 2.“As Alberta’s infrastructure ages, the risk of culvert failures under major roads throughout the province increases, which can result in sinkholes, road damage and flooding,” said the ministry. “These result in excessive costs to government agencies that have to fix/replace pipes at emergency rates; private land owners who are often affected by flooding damage; and road users in terms of travel disruptions and delays. The conventional solution is to treat such damaged culverts by installing liners or replacing the culvert, both of which are costly and disruptive to traffic.”

The Ministry of Transportation was interested in CentriPipe for several reasons. For one, it is cost effective. “In the ideal case,” says the ministry, “… the cost savings can be 60 per cent or more compared to conventional steel pipe lining option.”

RELATED: Combination of Trenchless Methods Applied to Michigan Interceptor Project

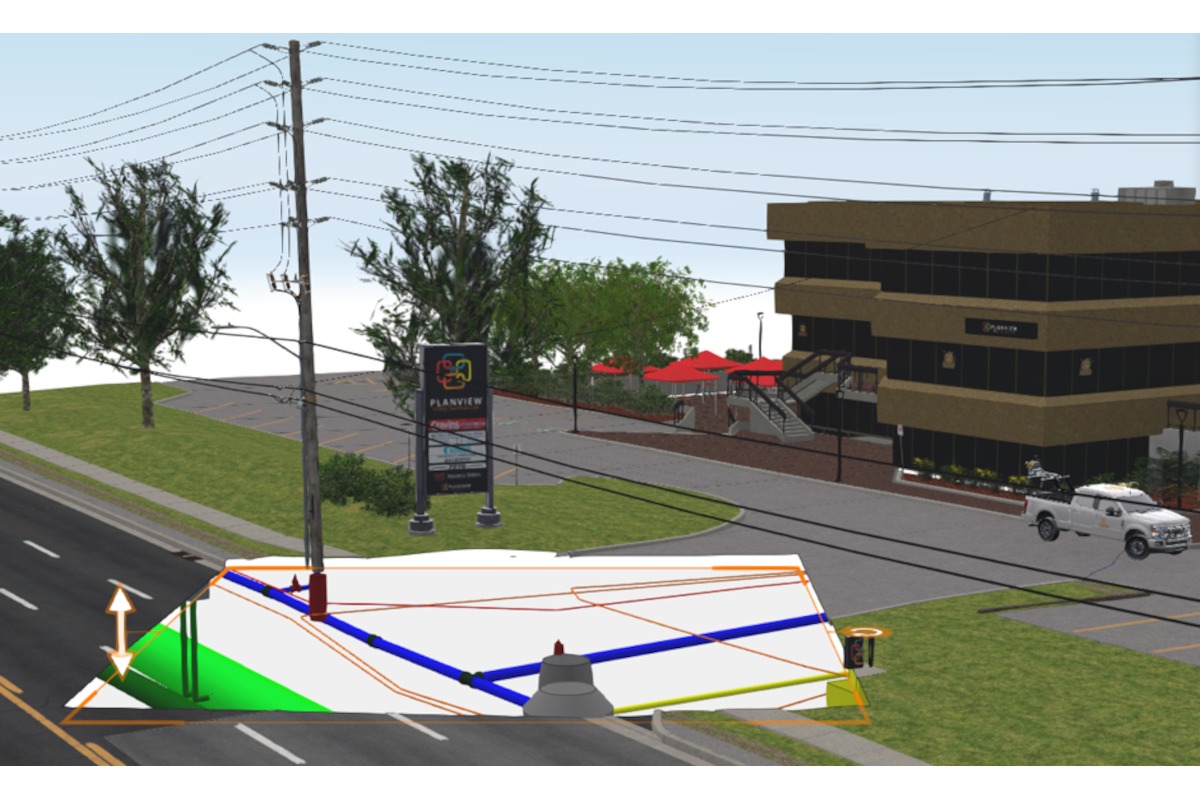

As the AP/M’s PL-8000 concrete is centrifugally cast evenly around the interior of the pipe, the application head is retracted by a computer-controlled motor at the properly calculated speed to ensure an even thickness predetermined by the engineer.

A Trenchless Solution

CentriPipe, a centrifugally cast concrete pipe process (CCCP) developed by AP/M Permaform, is a trenchless rehabilitation solution that requires relatively small staging areas — lane closures are rarely required. It is also a structurally sound repair.

The core of the system is a precisely controlled SpinCaster that is inserted into pipes and culverts and withdrawn at varying speeds while spraying thin, smooth layers of cementitious material. After two or more passes, the layers accrete into a new, strong pipe with a longer lifespan than corrugated metal pipe (CMP). This new pipe is thin-walled, about 1 in. in most applications, so pipe capacities are minimally affected—especially compared to sliplining.

Martech Inc. distributes the CentriPipe system in Canada, as well as Permacast, a related technology used to rehabilitate manholes. In Alberta, subcontractor OSCO Mudjacking & Shotcreting Ltd. (OSCO), handles the application.

Though the process is widely accepted by transportation departments and municipalities in the United States, the Athabasca project was the first use in Alberta, in fall 2013, and only the second use in all of Western Canada at that time. OSCO owner Don Moroz says that in some ways this was a routine use of CCCP.

“The culverts were in a state of deterioration. There was some sagging and corrosion, but not nearly the level of failure that can be successfully treated with CentriPipe,” he says. “Highway 2 is very busy, and if the culverts had failed the consequences would have been serious. So this was an excellent pilot project, and a good chance to show what CentriPipe can do.”

RELATED: More Than Manholes: AP/M Permaform Grows into Trenchless Solutions Provider

The CentriPipe spincaster is pulled through the pipe. The Athabasca project was the first use of this process in Alberta.

Onsite in Alberta

The Athabasca twin culverts were 48-in., cylindrical CMP culverts, running parallel beneath Highway 2, and about 33.5 m long. Work commenced during a dry period, so dewatering and bypass pumping were not needed. Prep work was mainly pressure washing with a wand. On some projects, where inverts are rotted out, a new concrete invert is poured to enable smooth movement of the CentriPipe sled-mounted spincaster, but that was not needed here.

Actual fieldwork went very smoothly and quickly — the OSCO crew was onsite for three days. After prepping the culverts, a concrete mixer, concrete pump and winch were set up in a modest staging area on one side of Highway 2, and the CentriPipe SpinCaster was inserted alternately into each culvert and withdrawn at controlled speeds to apply thin layers of cementitious material.

Each culvert received two passes, and a total thickness of 1-in. (above CMP corrugations) was applied. Detailed project design, including thickness and number of passes, was provided by AP/M Permaform and, after review, certified by a local engineering firm.

The material applied was PL-8,000, made by AP/M Permaform, a fiber-reinforced cementitious grout with short curing times, exceptional structural strength, and good adherence to most existing substrates, including CMP and HDPE. In this case, the PL-8,000 was also treated with Crystal-X an additive that improves waterproofing by forming millions of fine crystalline fibers inside capillary pores and micro-cracks while the material cures.

Waterproofing and substrate adherence are important features of the CentriPipe system; annular space between the new concrete pipe and the original substrate is completely filled, extending lifespan by inhibiting damaging water flow.

RELATED: NYSDOT Embraces Centrifugally Cast Concrete Pipe for Trenchless Storm Sewer Rehab

The Athabasca twin culverts were 48-in., cylindrical CMP culverts, running parallel beneath Highway 2, and about 33.5 m long.

Quality Control

For this pilot project, quality control was provided by an onsite technical expert from AP/M Permaform, and by Ministry of Transportation inspectors. Layer thickness was also verified with the use of simple depth gauges and by monitoring the volume of material applied.

The Athabasca project was completed in fall 2013, and inspected after three winters. The rehabilitation was judged to be structurally sound, and to have prevented further rusting of the original CMP culvert.

In its statement accompanying the 2015 Award of Excellence for Construction Innovation, Alberta Transportation stated, “CentriPipe has already been used in five other places in Alberta and is applicable to most large diameter culverts. This innovative process is extremely fast with minimal digging required, which saves money, reduces environmental impacts and creates less disruption to traffic.”

Angus W. Stocking, L.S. is a licensed land surveyor who has been writing about infrastructure since 2002.