TRACTO-TECHNIK Marks 50 Years

This equipment pulled drill rods and trench sheeting out of the ground. The main customer in those days was KRUPP Bautechnik in Essen.

The stable high pressure weather conditions on foundation day turned out to be a positive sign: in conjunction with the economical development all roads seemed to be leading upward in the years to follow. Still, it was not easy in the beginning.

Wolfgang Schmidt, the son of the company founder Paul Schmidt and the company director today, remembers: “My father was an optimistic person and looked at things from this angle. Whoever puts his head in the sand cannot discover anything new. In other words, he grabbed hold of every problem by the scruff of the neck when he believed that he could find a useful solution. Most of his results brought us forward very quickly. Our innovative strength grew through him and this is why, even nowadays, the driving factor and incentive are the main innovations.”

TRACTO-TECHNIK was still in its nursery years, but started to learn very quickly to stand on its own feet. The young company gained recognition and convinced with its own competence and innovation strength.

The company name was pre-programmed, as the first products carried the names TRACTODRILL and TRACTOMAT. TRACTOMAT won a coveted award in Brussels, “The Blue Band,” and is still applied today for the pulling of guard railing rods adjacent to roads.

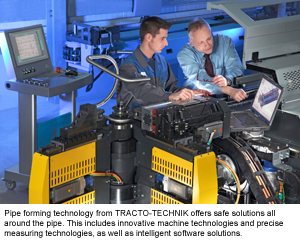

That was not all. A short time later, KRUPP presented a development consignment to TRACTO-TECHNIK for a hydraulically driven ramming device. The professional knowledge in the hydraulic field was obtained by Paul Schmidt and his colleagues at an evening school in Siegen. Afterward, they searched in vain for a machine for the handling of hydraulic tubes. This included cutting lengths, deburring, bending and the pre-assembly of cutter rings. In the end, Paul Schmidt looked at this casually. “If there is no such thing, then we will invent the machine,” he had said.

That was the birth of TUBOMAT and a new leg to stand on. The interest of the screwing manufacturers did not take long to arrive. Up until the beginning of the 1980s, the distributor was the company Kracht from Werdohl. Then TRACTO-TECHNIK took over the distribution on its own account.

The item company leaders are most happy about is the multiple thousand-fold proven TUBOMAT with small technical improvements to its original form, still being the yardstick with regards to hydraulic tubing and therefore still retaining its degree of esteem.

A small incident in 1970 led to a radical upheaval in the product politics. A fresh tarmac road in front of the Schmidt’s house had to be disrupted once again after only a few days, in order to install a water pipeline. This gave Paul Schmidt another clever idea.

The soil displacement hammer GRUNDOMAT was born – the start of many innovative developments for the trenchless pipe installation field.

A non-exemplary triumphal procession started. As world market leader the GRUNDOMAT soil displacement hammers are also “Global Players,” as they are applied on a daily basis all around the globe. For the trenchless installation technology the “mole” has become a strong symbol. It has become the marketing sign, which has won the trust and regards of TRACTO-TECHNIK’S customers.

Up to now more than 350 patents secure the researching and developments.

This has turned TRACTO-TECHNIK into a pacemaker and pioneer. TIMI (TRACTO IDEAS MAKE INNOVATIONS) makes sure that the innovation processes at TRACTO-TECHNIK have a true structure. The Avia Award from the economical examining engineers DELOITTE had lots of praise for this.

The broad-mindedness and enthusiasm for technology has provided numerous new developments. These have also brought a large amount of awards and tributes.

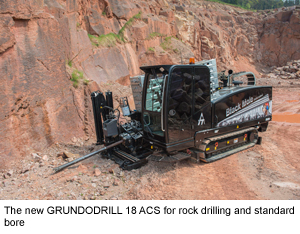

The steered bore technology has been especially fascinating. The tasks and requirements were diverse and lead the way to the level of technology available today via a non-exemplary development cycle. They were true pioneering achievements. Always new ideas on the board – arising from daily practical experiences – which were converted into this rather young technology under the motto: The better is the enemy of the good.

The company Beerman from Hörstel-Riesenbeck is currently working with 20 GRUNDODRILL bore rigs. Company owner Ewald Beerman has come to a positive conclusion: “Due to our collective experiences we have gained from each other over the years, we hold TRACTO-TECHNIK in high esteem, especially as they are always ready to listen to the challenges of the market, their innovative performances, as well as their reliability.”

The latest product is a bore rig for the installation of house connections, which is applied out of a so-called keyhole with a diameter of only 65 cm.

A further center of focus is the underground renewal of pipes with the GRUNDOBURST technology. Service and sewage pipes in need of sanitation are replaced in the same bore path by pipes of the same size, or even larger pipes with the relevant hydraulic power and providing a new effective service life for decades. The chief aspect is a patented QuickLock bursting rod, which is not screwed, but is simply latched into place

The production was constantly adapted to meet the requirements with the modern CNC manufacturing technology. The aim was always to increase the productivity, but mainly to have a solid quality for a highly reliable and long service life of the products.

TRACTO-TECHNIK has more than 500 employees on a world-wide basis. TRACTO-TECHNIK knows that only satisfied and competent employees are also able to keep the customers satisfied. There is a very strong bonding force between the employees and the company — 85 employees have been at TRACTO-TECHNIK since the beginning of their apprenticeships while some of them have spent all their working years here.

In the 1980s, the company started to accelerate and started to spread out all over the globe, first of all in England, then in France, the United States and Australia. The TT export department and the sister companies take care of and support more than 60 partners all over the world.

In Germany, the service in all regions is covered by the plants and the many subsidiaries.

TRACTO-TECHNIK has got clear eco-political targets, which are thoroughly and constantly encouraged, as well as an environmental friendly machine technology and also numerous ecological projects. In the meantime the nature protection board (NABU) has implemented the trenchless pipe installation method into its general directives.

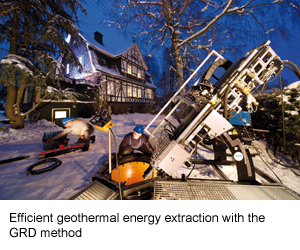

In 2007 the GRD bore technology arrived for an efficient exploitation of geothermal energy. Bores are carried out from a plastic manhole in all directions and inclinations. The compact bore rig is applicable even on the tightest premises and hardly causes any surface damage.

Continuity and stability have always been benchmarks in the company’s policy. Company directors Timotheus Hofmeister and Meinolf Rameil like to state more precisely: “Our aim is for endurable and profitable growth. To do so we need products in line with the market and a powerful distribution force with a clear strategic alignment. We can only achieve this as a team.”

The challenges of the future are seen by TRACTO-TECHNIK in a modern and safe supply and disposal in the energy and communication field, where technologies and methods of the trenchless pipe installation can contribute substantially.

This article was submitted by TRACTO-TECHNIK GmbH & Co. KG, Lennestadt, Germany.

|  |

|  |

|  |

|  |

|