SPR Spiral-Wound Pipe in Stendal, Germany

August 24, 2011

Following a series of successful applications, the SPR spiral-wound pipe liner has been used more and more since its market launch in Germany in 2008. The SPR method enables defective sewer lines to be rehabilitated with a spiral-wound pipe liner formed of endless steel-reinforced PVC profile strips inside the sewer.

Following a series of successful applications, the SPR spiral-wound pipe liner has been used more and more since its market launch in Germany in 2008. The SPR method enables defective sewer lines to be rehabilitated with a spiral-wound pipe liner formed of endless steel-reinforced PVC profile strips inside the sewer. The latest rehabilitation of the “canalized Uchte” in Stendal by specialists from the Brehna office of KMG Pipe Technologies GmbH shows that even exotic profiles with large nominal diameters can be rehabilitated by this method.

Historic Structure in Stendal

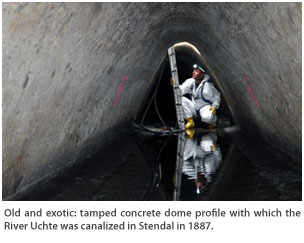

One of the oldest parts of Stendal’s subterranean infrastructure is the “canalized Uchte.” As early as 1887

One of the oldest parts of Stendal’s subterranean infrastructure is the “canalized Uchte.” As early as 1887 the River Uchte, which used to flow openly through Stendal town center, was “tamed” by canalizing the water course. For this purpose, a dome profile sewer with a crown height of 1.74 m and bottom width of 1.50 m was built in the present-day alignment of Bruchstraße. The sewer was constructed in tamped concrete on a brick foundation – a technology applied to many structures at that time. After 130 years of continuous use, however, these structures are fraught with the same problems: The integrity of the concrete is weakened, the walls are becoming porous and no longer watertight, their surface is disintegrating and they are becoming unstable.

Unusual Structural Design

Due to the traffic load, especially below a main street such as Bruchstraße in Stendal’s town center with a minimum coverage of only 15 cm in some places, it was threatened with imminent collapse. Action was needed. Having recognized this danger, the owners of the “canalized Uchte” instructed Magdeburg-based engineering office MUTING GmbH to prepare a rehabilitation concept. One option was quickly excluded: renewal of the old structure by the open-cut method. That would have been highly labor-intensive and costly due to the unstable subsurface conditions and constantly high groundwater table. Furthermore, reconstruction would have taken much longer – an impossible scenario in the center of Stendal’s business district, particularly since Bruchstraße is currently undergoing a full facelift as part of the town center redevelopment. In addition, Bruchstraße is an archaeologically sensitive site, as it is immediately adjacent to Marienkirche and crosses a century-old burial ground.

Due to the traffic load, especially below a main street such as Bruchstraße in Stendal’s town center with a minimum coverage of only 15 cm in some places, it was threatened with imminent collapse. Action was needed. Having recognized this danger, the owners of the “canalized Uchte” instructed Magdeburg-based engineering office MUTING GmbH to prepare a rehabilitation concept. One option was quickly excluded: renewal of the old structure by the open-cut method. That would have been highly labor-intensive and costly due to the unstable subsurface conditions and constantly high groundwater table. Furthermore, reconstruction would have taken much longer – an impossible scenario in the center of Stendal’s business district, particularly since Bruchstraße is currently undergoing a full facelift as part of the town center redevelopment. In addition, Bruchstraße is an archaeologically sensitive site, as it is immediately adjacent to Marienkirche and crosses a century-old burial ground. Trenchless Was the Solution

A key consideration in opting for the trenchless rehabilitation method was the reliable restoration of the necessary stability of the old structure. After a careful technical analysis the authorities decided against short pipe relining and in favor of the SPR spiral-wound pipe lining method. This option was offered by the Brehna branch of KMG Pipe Technologies GmbH, a subsidiary of SEKISUI SPR, Schieder-Schwalenberg. The deciding factor in Stendal was that the spiral-wound pipe lining could be installed using the existing manholes – without the excavations usually needed for laying short pipes. Thanks to trenchless installation, the road resurfacing work was performed parallel to the sewer rehabilitation.

The Process

The SPR method is a cutting-edge version of spiral-wound pipe lining technology. The basic principle of SPR spiral-wound pipe rehabilitation is that the decayed sewer section is repaired using an endless PVC-U or HDPE profile strip (spiral-wound pipe).

The endless profile strip, wound on a drum, is fed into the sewer through an open manhole and joined by a spiral-winding machine installed in the sewer to form a pipe by a tongue and groove technique. Liners of practically any length can thus be created: As soon as one of the above-ground profile drums is empty, a new coil is joined onto it by the heated tool butt welding method. Apart from this short interruption, the SPR method permits continuous working.

A major advantage of the spiral winding method is its extreme flexibility in irregular cross-sections and where open trench construction is to be avoided. The SPR spiral-wound pipe lining method can be used not only in standard-sized circular and egg-shaped profiles, but also special profiles of every conceivable type and dimension up to DN 5000. For a new situation, as was the case with the special dome profile of the “canalized Uchte,” the winding frame only needed to be adjusted to the dimensions and cross-section of the structure to be rehabilitated. This sewer data had been precisely determined in the structure beforehand using a 3D laser scan to ensure unhindered passage of the spiral-winding machine. The special feature of SPR technology is that the machine does not remain in the starting shaft, pushing the spiral-wound material into the sewer ahead of it. Instead, the unique winding frame crawls along the full length of the structure, forming the spiral-wound pipe from the profile strips trailing behind it.

A major advantage of the spiral winding method is its extreme flexibility in irregular cross-sections and where open trench construction is to be avoided. The SPR spiral-wound pipe lining method can be used not only in standard-sized circular and egg-shaped profiles, but also special profiles of every conceivable type and dimension up to DN 5000. For a new situation, as was the case with the special dome profile of the “canalized Uchte,” the winding frame only needed to be adjusted to the dimensions and cross-section of the structure to be rehabilitated. This sewer data had been precisely determined in the structure beforehand using a 3D laser scan to ensure unhindered passage of the spiral-winding machine. The special feature of SPR technology is that the machine does not remain in the starting shaft, pushing the spiral-wound material into the sewer ahead of it. Instead, the unique winding frame crawls along the full length of the structure, forming the spiral-wound pipe from the profile strips trailing behind it.Waterproofness and stability are, however, not the only structural benefits of the spiral-wound liner as a rehabilitation system. The spiral-winding process intentionally leaves a defined annular space between the SPR liner and the old pipe, into which a high-strength mortar is injected in a subsequent work stage. In addition, the annular space is walled off and cells filled at regular intervals. Ultimately, the SPR liner serves “only” as formwork for a new concrete inner shell of the old sewer and in the long-term it provides a reliable protective layer to shield the concrete structure from the effects of sewage and sewer atmosphere. Logically, the annular space is not minimized at the planning stage, but consciously defined according to static requirements. In the dimensioning of the SPR liner it is not a matter of “as little annular space as possible,” but “as much annular space as (statically) required.” Whether the resulting reduced cross-section is acceptable compared to the old pipe is a question of the hydraulic analysis necessary for each individual case in the course of planning. The extremely good friction coefficients of the new, smooth SPR liner have the positive effect that the reduction in diameter is already partially compensated for.

Intakes Open during Winding

Several feed conduits enter the “canalized Uchte” in the course of the section to be rehabilitated — these had to be reconnected after rehabilitation work. For this purpose, the liner was opened at the precisely measured and color-marked position of the conduits and a PVC pipe of the appropriate diameter inserted into the intake. Spiral winding technology thus enables the inflow from the feed conduit to be maintained. To prevent material from obstructing the junctions when the annular space was subsequently sealed, the entry points were closed off with deep plugs, which were removed after the sealant had hardened. In a final stage the intake pipes were milled off flush and cleanly connected by GRP hand laminate to the inside wall of the new sewer.

Several feed conduits enter the “canalized Uchte” in the course of the section to be rehabilitated — these had to be reconnected after rehabilitation work. For this purpose, the liner was opened at the precisely measured and color-marked position of the conduits and a PVC pipe of the appropriate diameter inserted into the intake. Spiral winding technology thus enables the inflow from the feed conduit to be maintained. To prevent material from obstructing the junctions when the annular space was subsequently sealed, the entry points were closed off with deep plugs, which were removed after the sealant had hardened. In a final stage the intake pipes were milled off flush and cleanly connected by GRP hand laminate to the inside wall of the new sewer. Second Generation Material

Particularly pleasing from the point of view of KMG Pipe Technologies is the fact that in view of the obvious advantages of the system, municipal network operators have overcome their historic reservations in respect of the material PVC. In recent years the nationwide bans – some of them instigated in the 1970s – have been lifted following an updated ecological evaluation of the material, giving further rise to confidence that the certified SPR spiral-wound pipe lining method will consolidate its position in the sewer rehabilitation market in the near future.

Particularly pleasing from the point of view of KMG Pipe Technologies is the fact that in view of the obvious advantages of the system, municipal network operators have overcome their historic reservations in respect of the material PVC. In recent years the nationwide bans – some of them instigated in the 1970s – have been lifted following an updated ecological evaluation of the material, giving further rise to confidence that the certified SPR spiral-wound pipe lining method will consolidate its position in the sewer rehabilitation market in the near future. Interest in the procedure is considerable. At an open viewing of the construction site in Stendal’s Bruchstraße from May 17-19, 2011, sewage experts from authorities and water boards including Kiel, Magdeburg and Erfurt were able to inform themselves of the possible uses of the SPR method in difficult situations. Among them were employees of the Berlin water utilities responsible for sewer rehabilitation. All of them took a critical look at the spiral-wound dome profile liner below ground. Meanwhile the construction site belongs to the KMG rehabilitation experts alone. They are confident that the contract will be completed on time by mid-July 2011.

This article was submitted by SEKISUI SPR Europe and KMG Pipe Technologies GmbH.