Sliplining: Quality Control Procedures and Risk Mitigation

Trenchless sliplining is a time-tested and effective technique for rehabilitating existing pipelines without the need for extensive excavation. This method allows for the reinforcement and repair of aging or damaged pipes, reducing the environmental impact and minimizing disruption to local communities.

Sliplining rehabilitates pipelines by inserting a new pipe within the existing (host) pipe alignment. This technique is widely used for the rehabilitation of sanitary sewers, water, and storm water mains due to its cost-effectiveness.

Despite its advantages, there are risks associated with slipline design and construction implementation. Sliplining projects should implement quality control procedures and effective risk mitigation strategies to reduce risk and increase the chance of success.

The Sliplining Procedure

The sliplining design and construction involves several key steps:

1. Assessment and Inspection

An assessment of the existing pipeline should be completed. Techniques such as CCTV inspection, sonar, and other non-destructive testing methods identify the extent of damage, structural integrity, and dimensions of the host pipe.

2.Pipe Selection

Based on the conditions found in the assessment, an appropriate liner pipe material is chosen. Common materials used for sliplining include High-Density Polyethylene (HDPE), Fiberglass Reinforced Polymer (FRP), or other suitable pipes. The selection depends on factors such as site constraints, load-bearing capabilities, and flow capacity.

3.Preparation of Host Pipe

Prior to inserting the new liner pipe, the host pipe must be prepared. This may involve cleaning out debris, ensuring the interior surface is smooth, and performing repairs if certain sections of the pipe are damaged.

4.Insertion of Liner

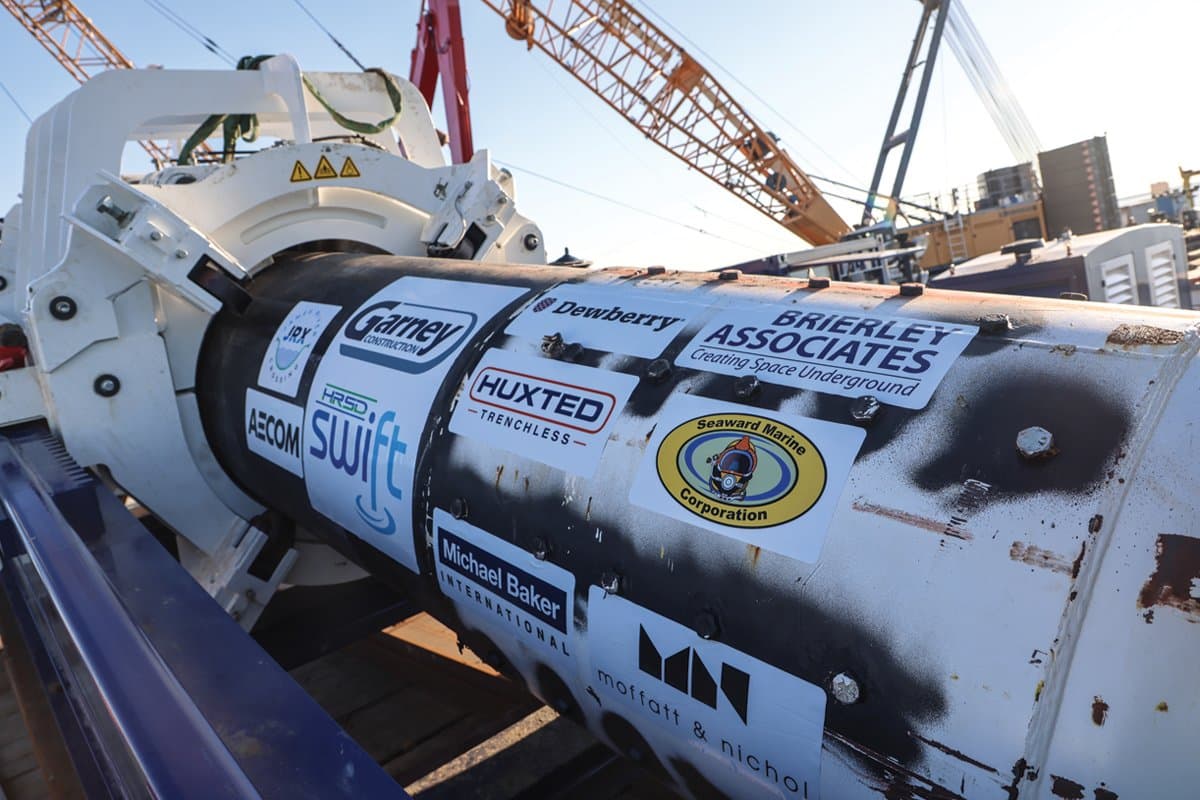

The new liner is inserted into the host pipe. This is typically performed using winches, excavators with slings, or a combination of both. Using segmented pipe allows for installation in “live flow” conditions in sewer and storm pipe.

5.Sealing and Grouting

Once the liner is in place, the annular space between the host and liner pipe should be grouted for structural integrity and to create a watertight seal. This step helps prevent movement of the liner and provides additional stability.