Rock Tooling Options for HDD

Arguably, bit selection to obtain optimum drilling efficiency and economy for the given ground conditions is the most critical issue for HDD in rock. Pilot holes can be drilled using rotary, roller cone or percussive techniques depending on the mechanical properties of the material to be drilled.

Rock “hardness” measured by compressive strength in psi or MPa, is a major consideration. This is defined as the maximum compressive stress that, under a gradually applied load, a given solid material will sustain without fracture.

Rotary Drilling – PDC Bits

Rocks of low to medium hardness (up to 25,000 psi compressive strength) are usually suitable for rotary drilling; these will include sand, shale, mudstone, sandstone and limestone.

A modern example of rotary cutting tools are PDC bits. They use a synthetic diamond cutter to shear the surface of the rock. PDC bits have several advantages which include:

- They offer a higher rate of penetration, longer life and increased steerability compared to conventional methods

- No moving parts

- Less stress on the drill rig

- Lower torque required

- Less vibration on the drill rods

- Producing clean holes with a consistent size

- Repairable

- Diameters from 1-7/8 to 18 in. typically

Drilling with Roller Cones – Tricones

Tricones have a range of designs and specifications making them suitable for a wide variety of rock formations. Mill Tooth tricones are designed for drilling rock up to approximately 6,000 psi compressive strength, whereas TCI tricones have designs available that are suitable from 5,000 psi to over 50,000 psi. Rock types include soft sandstone and limestone through to Basalt.

RELATED: Let’s Talk HDD Tooling

The roller cones on a tricone bit rotate together with the drill rod and cut the rock without percussion under pressure provided by the drill rod from the surface. Inserts situated on the surface of the roller cones penetrate the rock under pressure and crush it.

Tricones have a number of advantages and include:

- Versatility – Option for nearly every type of rock

- Low in initial investment

- Excellent impact resistance which makes them suitable when the rock is fractured.

- Diameters from 2-15/16 to 26 in. typically

Percussive Drilling

Down the hole (DTH) Hammers are excellent when ground conditions are very hard, especially above 30,000 psi compressive strength. Rock types include hard limestone, granite and basalt.

DTH drilling uses a pneumatic hammer directly behind a carbide impregnated drill bit. The bit is held against the rock surface under load and the impact from the hammer shatters the rock.

RELATED: HDD Tech Talk: Managing Your Drill Pipe Investment

DTH Hammers and bits have several advantages and include:

- Faster penetration rates in very hard rock

- Directional hammer bits are usually supplied as either Convex or Slant face bits depending on the ground conditions

- Lower wear rates in abrasive ground conditions, especially above 30,000 psi

- Suitable for solid rock

- Diameters from 4 to 7-1/2 in. typically

Hole Opening / Reaming

As well as the above pilot hole techniques, rotary drilling can be used for hole opening where larger bore diameters are required.

PDC Reamers

PDC reamers work on the same principle as PDC bits with a synthetic diamond insert shearing the rock.

- Reaming up to 12 in. extra diameter in 1 pass (e.g. 6- pilot to 18 in.)

- Less stress on the drill rig – lower torque required and less vibration on the rods

- No moving parts for increased reliability

- Clean holes with a consistent size

- Repairable and replaceable cutters

- Diameters from 4” to 7-1/2” typically

Hole Openers

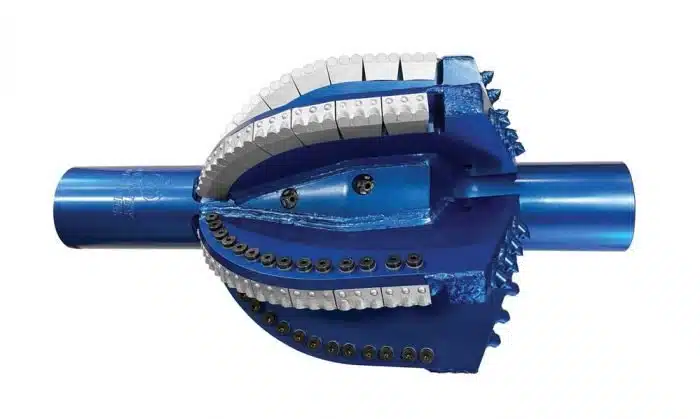

Hole Openers use similar cones to tricones arranged around a central body to open the pilot hole up to the required finished size.

- Cost-effective solution

- Enable larger holes to be drilled with smaller rigs by drilling in stages.

- Usually up to 4-in. diameter hole opening, depending on ground conditions

- 8- to 60-in. diameters

- Mill Tooth or TCI

- Standard 5 cone – other options available

- Diameters from 8 to 48 in. typically

Infinity has several resources available online to help their customers choose the best bit infinitytoolmfg.com/resources.

Keith Jackson is the international sales director/global marketing for Infinity Tool Mfg.