QA, QC Protocols Integral to Successful Trenchless Relining Projects

September 7, 2016

The overall success of a construction project — no matter how big or small — often depends on the levels of quality assurance and quality control that all parties involved in the project adhere. This is even truer when working in the trenchless world, as much of the work is done underground and out of sight.

Not unlike other sectors of the construction industry, the key to a quality project are qualified and trained designers, contractors and inspectors. These trained individuals are the front line in making sure QA/QC measures are met, and this is an area where NASTT, NASSCO and TTC, among others, shine.

It is important to note that while many people use quality assurance (QA) and quality control (QC) interchangeably, they are not the same. The American Society for Quality (ASQ) defines QA as, the planned and systematic activities implemented in a quality system so that quality requirements for a product or service will be fulfilled and QC are the observation techniques and activities used to fulfill requirements for quality.

RELATED: Storm, Sanitary Systems Still at Top of Relining Heap but Pressure Pipe, Laterals Poised for Growth

Looking at this in terms of a trenchless relining project, QA comes on the front end of the project in the condition assessment and design phase. The owner agency is assured that the project it is putting out to tender is the one that will address the desired outcome. Quality control deals with the contractors and materials used and ensuring the installation and finished product are as prescribed.

“You can have a job without any quality control standards and it can be a good job. That happens, but when you look at the overall picture, projects that have a good quality system have a much greater chance of being a successful project,” says Lynn Osborn, technical director, NASSCO. “Pipelines fail for a lot of reasons, but two reasons are that low quality materials are installed or the installation is poor. Both can be included in a quality program making certain the right materials are selected and the correct installation procedures are used. That goes a long way toward determining the success, as far as quality is concerned, of the project.”

Osborn sees QA/QC as a three-legged stool. To have a quality product that will meet the owner’s requirements requires good engineering design, qualified installers and trained inspectors. When the first relining projects took place, contractors would bid on a job and, if they won the bid, they would go ahead and tackle the project. Once complete, the extent of sampling or review might be a grainy CCTV video that the owner would review and nothing more. If the project failed, the owner likely wouldn’t revisit trenchless in fear of being burned again.

RELATED: U.K. Fresh Water Pipe Relining Project Proves to be a Challenge

Mike Willmets, NASTT executive director, recalls one of the early potable water relining projects he worked on as the project manager for the Region of Ottawa-Carleton, Ontario. This was in the early days of potable water pipe relining and the contractor took what they knew about gravity pipe lining and applied it to pressure pipe. Unfortunately, there was always the risk of the exterior liner resins clogging the service connections.

“Some of the first contracts we did had problems, not problems that could not be fixed, but problems that cost additional funds,” Willmets says. “As you move forward, you realize there might be a better way to complete these projects in more timely and economic fashion.”

The fix for the clogged service connections was as simple as adding a temporary plug to the connections to avoid the resin migration. In the end, the plugging perfected the process ensuring the savings that are typical of a trenchless solution — cheaper, faster and greener.

“There are generally few cast in stone regulations for this practices and that is where organizations like NASTT comes in and where the value of networking can play a major role. When I worked for the municipal government, I’d engage other city employees at engineering events and other functions where we would chew the industry fat,” Willmets says. “This brought a net benefit to everybody because sometimes they would have issues we never thought of and the dialogue helped us all in the long run. I always shared our specs with others because they were public documents and we worked very hard on developing early specs. Sharing knowledge with others helped them get a start in alternative solutions with innovative products and I believe helped grow the trenchless industry.”

It is through this trial- and-error effort across the industry and via associations like NASSCO, NASTT, ASTM and ASCE that standards started and continue to evolve.

“When we talk about lining, QA and QC applies to everyone,” says Dr. Tom Iseley, director of the Trenchless Technology Center (TTC) at Louisiana Tech University. “There is a tendency to think that QA and QC only come in to play during the construction phase and through inspections. It must be built in to every aspect of the project.”

This starts at the condition assessment phase and using a variety of tools to determine the problem and the proper repair(s) for the conditions. With a quality assessment complete, the owner and design engineer work in tandem to determine the best specification for repair taking into consideration pipe type, pipe condition and desired outcome. The owner can put the best possible project out and the right contractors will submit the best bids.

For example, Iseley cites a city having an inflow and infiltration (I/I) problem and the city has an excellent QA/QC process for relining pipes. However, when the city and its design engineer put the project together it only addresses the pipe and not the service connections and manholes. The project scope needs to address all three in order for the city to receive the I/I benefits it originally hoped.

RELATED: Picking the Brain of: Ken Foster

“So many times we see where QA and QC is placed solely on the backs of contractors and there are poor and inadequate contract documents produced,” Iseley says. “They [the owners] expect the contractor to do magic and have a perfect project. Contractors can only do so much.”

As the trenchless industry matures, asset owners are becoming more cognizant of the importance of a full quality assurance and quality control program when working on a project.

Putting the best possible project out with the correct specifications is paramount in a day and age of increased scrutiny from regulators, environmental agencies and the public alike. Willmets notes that the increased scrutiny means a project has to be “pretty much bullet proof,” before it gets off the ground.

“For every dime you spend, you better make sure that you are doing it exactly as you should in the most efficient way that you should,” Willmets says.

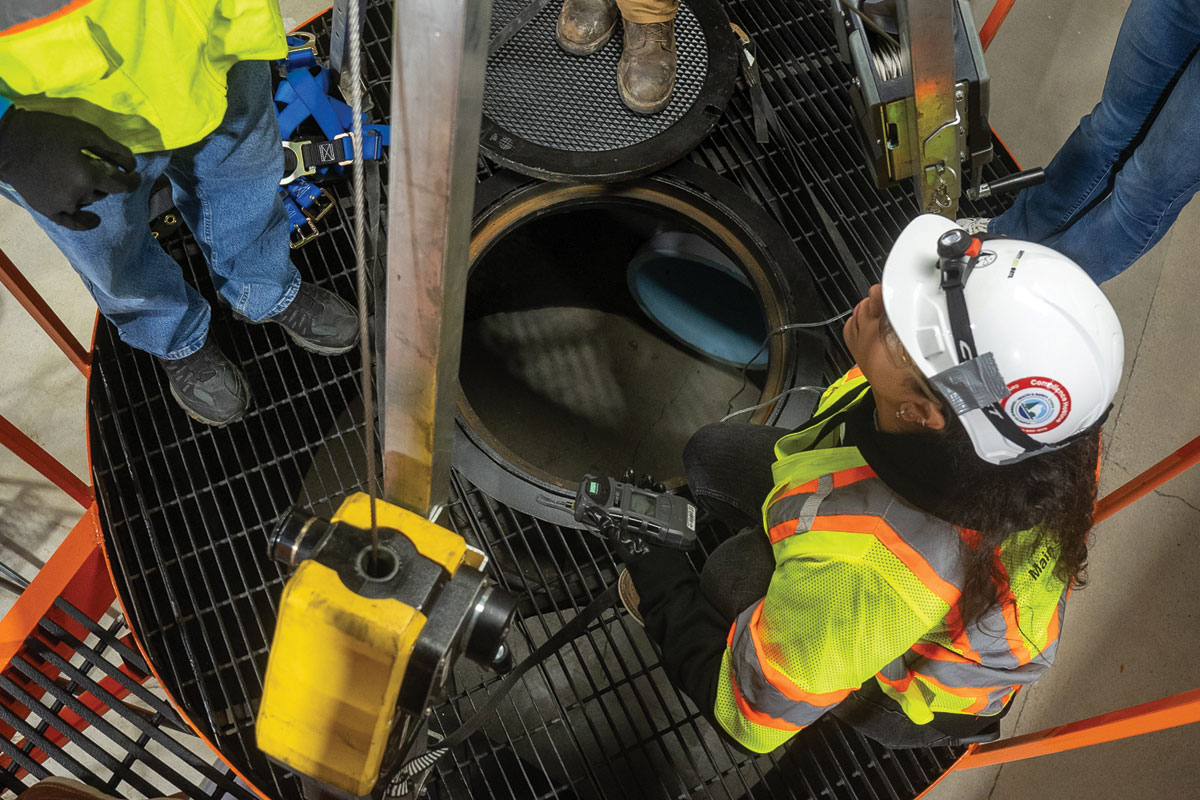

On the quality control side, an owner must perform due diligence to make sure the approved contractor is qualified to meet the project specifications. In recent years, owners have increasingly required contractor pre-qualification before bidding. Once the project is under way and through completion, a qualified inspector should monitor the project for the owner. Quality control measures must be clearly defined in the project specifications and include material sampling, CCTV inspections and data logging.

“As the industry matures, we will see standards developed and the ones that are out there will be revised.” Iseley says. “We need to see more focus on training, not just for the overall construction process, but training that goes into designing and planning projects as well.”

Not unlike other sectors of the construction industry, the key to a quality project are qualified and trained designers, contractors and inspectors. These trained individuals are the front line in making sure QA/QC measures are met, and this is an area where NASTT, NASSCO and TTC, among others, shine. Willmets points to the NASTT website, where course offerings are listed as well as technical papers from 1991 to present, many of which cover QA/QC. And NASSCO is known for its Pipeline Assessment & Certification Program (PACP,) Manhole Assessment & Certification Program (MACP) and Lateral Assessment & Certification Program (LACP), as well as its Inspector Training and Certification Program (ITCP).

Mike Kezdi is associate editor of Trenchless Technology.