NOLA Welcomes WEFTEC 2018 – Trenchless Product Preview

RAPIDVIEW IBAK

RAPIDVIEW IBAK

RapidView IBAK North America is proud to showcase our newest evolution of compact inspection system design. Years of market research and engineering has resulted in a sleek, easy-to-use system that won’t strain your back, or your pocketbook. Available in many different configurations, the MainLite systems can be used in portable applications, or mounted in vehicle, providing you power and flexibility in one compact, affordable package. See us at WEFTEC or visit us at rapidview.com. Booth # 7539

RAUSCH USA

RAUSCH USA

The brand-new LATRAS lateral tracking system is a modular upgrade to the Rausch M-Series product line for the automatic measuring and graphic documentation of the entire pipe laterals. The system’s control electronics capture the direction of motion of the LATRAS sensor head behind the digital lateral camera, KS 60 DB. These coordinates are registered constantly in parallel with the inspection and allow the documentation of the laterals at the same time without any significant additional work for the operator. With this new and important information about the pipe system the quality of the inspection is considerably improved. Booth #1606

RAVEN LINING

RAVEN LINING

VersaFlex Inc. and Raven Lining Systems announced earlier this year that the two companies have merged. The joining of these powerful brands in the specialty coatings industry allows the new company to expand and build upon combined expertise in polyurea, polyurethane, epoxy and cementitious technologies to better serve its global customers. A key shared value of VersaFlex and Raven is the commitment to working closely with best-in-class coating applicators dedicated to the highest quality standards. The company’s plan is to combine VersaFlex’s POLYUREA University with Raven’s Certified Applicator Program to develop an industry leading training and technical support program. Both VersaFlex and Raven are ISO 9001:2008 certified for operations. VersaFlex brings the additional quality strength of being ISO 9001:2008 certified for design. Booth #3017

ROOTX

ROOTX

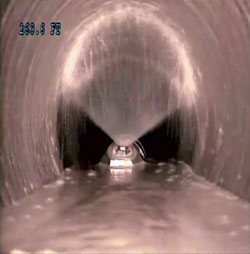

RootX was engineered to limit the exposure issues and environmental impacts that other root control formulas were producing and to remove pipeline roots without affecting the treatment systems at the wastewater treatment plant downstream. RootX was also engineered for fast, simple and cost-effective applications that don’t require extensive training or expensive add-on equipment. Save time and money by using your own crew and equipment to clear pipe blockages and eliminate the need to hire and schedule special contractors. RootX is registered with the EPA and has a low environmental impact, making it the go-to solution for municipal systems nationwide. RootX is easier to apply than ever before with the new FDU 300 applicator, engineered to make applying RootX to mainlines faster, easier, and more effective than ever. Within a month after applying RootX, roots are dead and decaying, keeping your lines moving for up to 36 months. Booth #2113

SAUEREISEN

SAUEREISEN

Sauereisen continues to innovate with materials and application methods for the municipal wastewater industry. Our materials prevent corrosion to potentially vulnerable concrete and steel infrastructure. In addition, Sauereisen products prohibit water inflow & infiltration, a prevalent problem in wastewater collection systems. Since entering the wastewater market over thirty years ago, our credibility has grown steadily. Sauereisen is positioned to lead with economical, user-friendly coatings and linings technology. These incorporate organic polymers specifically formulated for the municipal wastewater environment. Sauereisen’s epoxy-based SewerGard 210 family of products is designed to exhibit low permeability. This enhances corrosion resistance and extends the longevity of underground infrastructure such as manholes and lift stations. SewerGard is available in several variations to accommodate desired thickness and methods of application. Booth #5839