New South Carolina Water Main Provides for Future Needs

York County currently maintains approximately 128 miles of water main in its Eastern Water System ranging in sizes from 2 to 24 in. in diameter. Located just north of the Catawba River in the northeast corner of York County, the population has grown nearly 6 percent during the past three years to some 240,000 residents.

The water system is supplied through two sources: a connection to Charlotte Mecklenburg (N.C.) Utility Department (CMUD) to the north, and the Rock Hill (S.C.) Water Treatment Plant (WTP) to the south. Prior to the completion of this project, finished water was conveyed to York County from Rock Hill through the Fort Mill water distribution system via a 24-in. pipe on a utility bridge spanning the Catawba River. During periods of peak demand, this supply was inefficient, and York County also had to rely heavily upon the connection to the Charlotte utility.

The goal of this approximately $12 million, six-mile project is to construct a direct feed from the Rock Hill WTP to the Eastern Water System across the Catawba River with the capacity to meet the current and future demands of the system while remaining independent of the connections to CMUD and Fort Mill. The new water main will also provide redundancy to the water systems north of the Catawba River. As a result, York County will have the capacity to serve the projected demands of the Eastern Water System to the year 2030. The project was awarded to McKim & Creed Inc. (Raleigh, N.C.), an engineering, planning and geomatics firm.

“The purpose of the Catawba River Water Main project is to provide an alternative means of supply to the Eastern Water System,” explained Jacob VandenBosch, P.E., of McKim & Creed, who was the project engineer for the design and construction of the project. “The York County Eastern Water System is in an area that has seen significant growth over the past decade. The municipalities in this region include the Town of Fort Mill and the City of Tega Cay. The Eastern Water System serves mainly the commercial and residential developments located outside of the incorporated city limits and is a part of an interconnected web of distribution systems, owned and operated by York County, Tega Cay and Fort Mill. During periods of peak demand, the supply was inadequate to meet the demands of Fort Mill, Tega Cay, and York County and did not provide the needed pressure gradient to operate the system and fill the elevated tanks. As a result, York County relied upon the connection to CMUD to meet demands which led to increased costs associated with CMUD’s higher unit price of water.

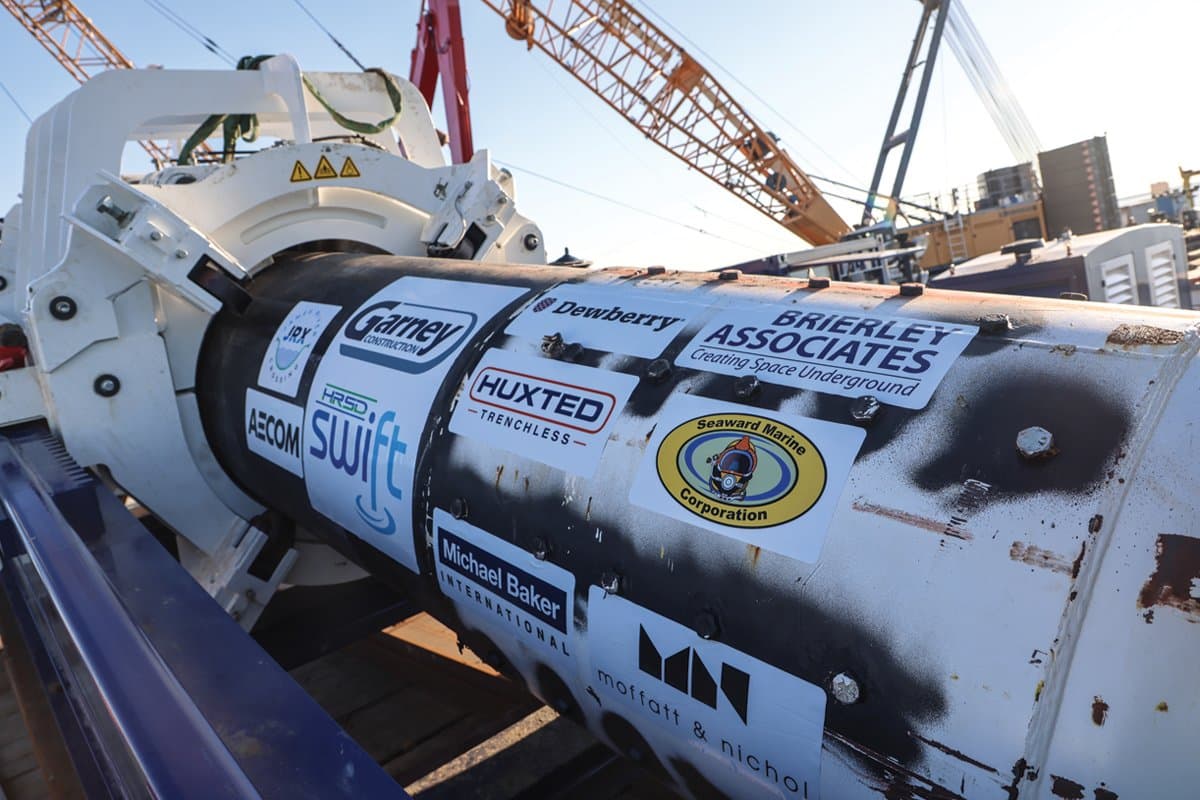

“Our greatest challenge to the design and construction of the new water main,” he explained, “was the installation of the pipe under the Catawba River, which occurred approximately 500 ft downstream from the Lake Wylie Dam. The installation was done using horizontal directional drill (HDD) technology to bring nearly 1,000 ft of large diameter, high-density polyethylene (HDPE) pipe 30 ft under the river.”

“York County is getting ahead of the problem with a logical solution,” stated Tony Radoszewski, president of the Plastics Pipe Institute Inc. (PPI), the major trade association representing all segments of the plastic pipe industry. “They are not waiting to be reactive and play catch-up later. They are forward-thinking leaders who are using the latest techniques and materials to provide for the future needs of the citizens and businesses. Projected current demand is 5.98 million gals a day. And they are aiming for 8.16 million gals a day in 2027 — more than a 35 percent increase. The goal was to install a cost-effective, trenchless and long-term solution that can deliver water for 100 years. The PE 4710 pipe is the right choice to deliver those requirements.”

Factors for choosing the Catawba River crossing location included access, environmental buffer regulations, HDD operation constraints, topography profile and easement requirements.

The technical feasibility of HDD installation at a given location can be determined by three parameters: drilled length, pipe diameter and subsurface conditions. With the anticipated length of the drill being approximately 1,000 ft, the length and diameter were found to be well within current HDD technology. With respect to subsurface conditions, large grain content in the soils, such as gravel and boulders, and excessive rock strength and hardness can hamper successful HDD installations. Additionally, poor rock quality and voids in the bedrock may impact the feasibility of a drilling operation. A geotechnical investigation was performed through the use of soil bores and rock cores at the anticipated entry and exit location of the drill to determine the parameters of the existing soil and rock conditions.

The site was explored by drilling four test borings — two on each side of the river — and analyzing the material from the borings. The borings extended to depths ranging from 21.5 ft to 30 ft below the existing grade using hollow-stem, continuous flight auger drilling techniques. Rock coring techniques were performed for two of the borings to an approximate depth of 90 ft to determine the character and continuity of the rock encountered.

The general subsurface stratigraphy at the bore sites was comprised of residual soils consisting of sand and silt to as deep as 25 ft. Blow counts of the residual soils ranged from 4 to 29 blows a foot. Partially weathered rock was encountered 15 to 25 ft under the residual soils. Rock was sampled from depth ranging from 26 to 90 ft.

“In general, the cored rock consisted of igneous metamorphic rock with a Rock Quality Designation (RQD) value ranging from 90 percent to 100 percent,” said VandenBosch. “RQD values of 90 percent and higher are characterized as ‘excellent’ rock quality and favorable for tunneling conditions. Unconfined Compressive Strength tests were performed and values ranged from 11,000 to 22,000 psi.”

HDPE pipe with a DR 11 pressure rating and PE 4710 resin was chosen for HDD installation. The 50-ft sections of pipe were fused together using McElroy units.

“PE 4710 pipe allows for higher pressures and greater hydraulic capacities (increase in the pipe ID) due to its greater resistance to slow crack growth and other requirements,” stated Camille Rubeiz, P.E., director of engineering for PPI’s Municipal Division. “These high performance pipes are designed for water and wastewater applications meeting AWWA C901, AWWA C906 or ASTM F714 standards and others.

“Per the AWWA Executive Committee hearings, the safety factors for PE 4710 exceed 10 for predicted lifetime relative to 100-year service life and is 3.6 for yield stress (3,625 psi) relative to hydrostatic design stress (1,000 psi). In addition, a properly designed HDPE system that includes criteria such as working pressure, recurring and occasional water hammer and 100-year fatigue life, results in a PE 4710 pipe with larger pipe ID, higher DR and longer fatigue life than other plastics, as calculated in industry software programs such as PPI PACE.

“Additionally,” he continued, “HDPE pipe has an exceptional bending radius — 25 times outside diameter for the DR 11 pipe used in this project — which allows the pipe to adapt to challenging site conditions. Also for the long-term, HDPE pipe has a Hazen Williams C factor of 150 which does not change over time. This factor, however, is usually diminished over time in other pipe systems due to corrosion and tuberculation, which does not occur in HDPE pipes.”

In order to achieve an approximate 30 inch inside diameter for a DR 11 HDPE pipe, a 36 in. outside diameter casing pipe was required.

There would be a 913-ft run of HDPE pipe 30 ft below the river bed, entry and exit angles of 12 degrees, and a single, 24 degree sag bend at a radius of 1,500 ft. The design provided a minimum depth of cover of 30 ft from top of bank to top of bank using an assumed depth of the river bed. Steel pipe was also considered for its high tensile strength and operating pressure capability, but was ruled out due to high cost of corrosion protection and longer installation requirements due to the higher bending radius. The PE 4710 pipe provided flexibility for the HDD operation plus corrosion resistance and the 200 psi rating to meet the water pressure requirements.

The HDD installation beneath the Catawba River was completed in April 2013. “It took seven weeks from the start of the pilot hole to the pullback of the pipe.” stated VandenBosch. “The HDD contractor worked a schedule of 10 hours per day seven days a week for the first three weeks and then shifted to a 24-hour schedule. The contractor operated a horizontal drilling rig with a pull-back capacity of 500,000 lbs, a torque capacity of 48,000 ft-lbs, and a footprint of 100 x 50 ft. The pilot hole was successful and stayed within the required design tolerances. The pilot hole was performed with a 12-in. drill bit and exited three feet short and two feet to the left of the designed exit point. Reaming passes were made with 24-, 28-, 32-, 40- and 48- in. reamers. The pull back of the pipe was made in approximately eight hours with no issues.

“We are very proud of this project,” he related. “It received a 2014 North Carolina ACEC Engineering Excellence Award, and knowing that we’ve contributed to the positive growth of this area is particularly rewarding.”

Steve Cooper has been reporting on the water and pipe industries for several decades.

Comments are closed here.