Overview of Lateral and Main/Lateral Connection Lining and Sealing Technologies

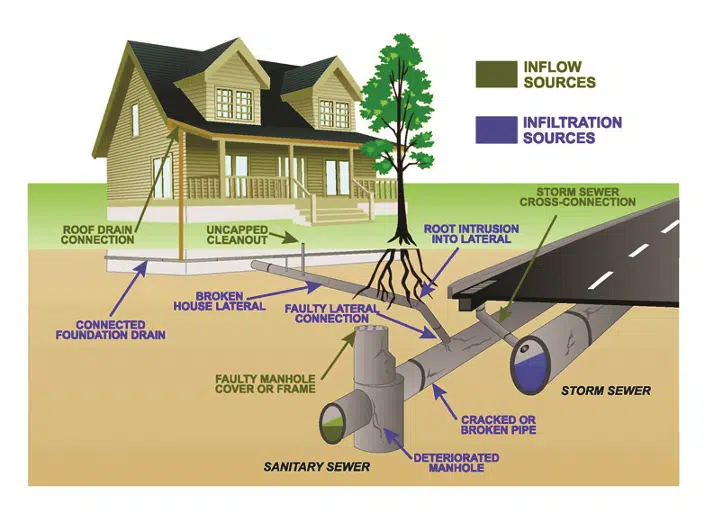

Several studies have confirmed that many of the lateral pipes in typical collection systems have reached their life expectancy and are either failing and/or contributing large amounts of I/I to the main sewer pipeline.

NASSCO is dedicated to informing the public and industry on advancements and utilization of trenchless technologies for the purpose of renewing and sealing laterals and lateral service connections. In many cases, plumbing codes do not specify the use of trenchless technologies, including lining, sealing, grouting or bursting as viable alternatives to excavation. Their use and advantage are still undiscovered by many, and yet these technologies have existed for years, confirming their viability as a proven resource for renewing infrastructure.

The NASSCO Lateral Committee has developed an overview technical document as an educational resource for advancing the acceptance of trenchless lateral rehabilitation. The Committee works with local system owners, state health departments and plumbing boards in an effort to educate owners on the advantages these technologies provide and enable acceptance into relative codes.

RELATED: NASSCO Marks Its 40th Anniversary

There are seven main approaches to consider when evaluating how to renew a lateral pipe:

• Sectional Pipe Lining – Repair by lining a portion of the lateral pipe.

• Lateral Pipe Lining – Repair by lining the entire lateral pipe.

• Main/Lateral Connection Lining – Repair by lining the lateral/mainline connection.

• Lateral and Main/Lateral Connection Lining – Repair by lining a portion of the lateral pipe or the entire lateral pipe and lining the lateral/main connection.

• Main/Lateral Connection Sealing – Repair by sealing the main/lateral connection by resin injection.

• Lateral and Main/Lateral Connection Grouting – Repair by sealing the main/lateral connection and the

entire lateral pipe (or a portion of the lateral Pipe) by chemical grout injection.

• Lateral Pipe Bursting – Replacement of either part of or the entire lateral pipe by pipe bursting.

The NASSCO overview document presents the advantages to assist with selection; however, system owners are encouraged to utilize the technical document as a guide in collaboration with their local consultants and contractors.

RELATED: The 4Ps of Sealing Laterals with Chemical Grout

CIPP for laterals closely follows the principles outlined in ASTM F 1216 and F 1743 and is capable of accommodating small diameters (4 in.) while maintaining a fully structural wall, navigating bends and enabling blind terminations, which allows installation from one point of direct access to the lateral (in most cases being an excavated installation pit or clean out). There are lining technologies that can be installed from the mainline, eliminating excavation altogether, and often will incorporate a seal for the lateral’s connection to the mainline. One hundred percent solids epoxy is a popular component enabling adhesion at the liner’s blind terminated opening, provided proper surface preparation of the host pipe has been employed. Typically, lateral lining with and without the lateral seal incorporates the use of a resin-impregnated tube installed by either water or air pressure and cured inside the host pipe by heat (water or steam), ambient temperature or UV light. Sectional CIPP systems can also accommodate laterals whether pulled-in-place or inverted into place when rehabilitation of a specific location is desired.

Lateral seals can stand apart from lateral lining when only the point of connection with the mainline sewer requires attention, whether due to ownership level or physical condition. Lateral seals are typically installed from the mainline and can travel up the lateral variable distances, depending on the technology type, but can range from 4 in. to several feet and, in some cases, continuing up the lateral to include lateral lining with the seal. The seal can incorporate either a brim style or complete wrap configuration at the point of connection with the mainline sewer, and the latest technologies enable watertight seals through gasket materials in addition to the resin systems.

Grouting presents an advantage by pumping reactive chemical grouts to reach behind broken sections of piping filling voids while effectively eliminating infiltration. Grout systems can accommodate both points of connection and locations within the lateral (or main). Grout packers are designed for either insertion from the mainline or from an existing cleanout.

These technologies are designed to be trenchless, but do not necessarily eliminate excavation altogether. In various cases, the repair system may warrant an access pit to gain access to a portion of the host pipeline. Other key elements when considering trenchless rehabilitation include CCTV inspection and host pipe cleaning, inclusive of such technologies designed to launch up the service lateral from the main line. Condition assessment and planning can make a substantial difference on projects where it is necessary to prioritize a large number of laterals. Technological improvements and new inventions continue to support and inspire this growing industry to meet the demand of aging infrastructure.

The NASSCO Lateral Committee is comprised of industry professionals including manufacturers, contractors, consultants and wastewater agencies throughout North America who provide a pool of knowledge capital and unite their experience and knowledge in an effort to reach out to the industry and promote educational resources and best practices for developing technical guidelines and specifications. The Lateral Committee meets quarterly to continuously refine and add technical content, research and present case studies to promote the further development of trenchless lateral rehabilitation.

The Lateral Committee encourages and welcomes participation. The “Overview” technical document can be found on NASSCO’s website, nassco.org, under the Industry News & Trends section.