HDPE in for the Long Haul Via HDD

April 22, 2016

Located to the south of historic Annapolis, Md., the community of Mayo occupies a peninsula between the South River to the northeast and the Rhode River to the southwest, both of which are connected to northern Chesapeake Bay. Regarded as one of Maryland’s most treasured natural resources, Chesapeake Bay is a favorite destination of recreational boaters and boasts significant crab and oyster fisheries.Anne Arundel County owns and operates the Mayo Water Reclamation Facility (MWRF), which receives septic tank effluent pumped from homes and businesses on the peninsula, treats the waste to meet current effluent standards, and discharges the treated effluent to the bay. The Maryland Department of the Environment (MDE) is requiring the County to upgrade the level of treatment provided for wastewater collected from the Mayo peninsula to achieve enhanced nutrient removal (ENR) performance by the state-wide deadline of January 2017.

In addition, limitations in treatment capacity had led the County to issue a moratorium on new development on the peninsula until additional wastewater treatment capacity could be provided. In 2013, the County selected GHD to assist with analysis of alternatives, project planning, and design. After detailed evaluation, it was determined that the most cost-effective means of providing ENR level treatment for all of the wastewater generated on the Mayo peninsula and to expand capacity to accommodate build-out within the existing service area was to decommission the MWRF and pump the wastewater to a larger treatment facility in Annapolis that was also operated by the County and had already upgraded for ENR performance.

In addition, limitations in treatment capacity had led the County to issue a moratorium on new development on the peninsula until additional wastewater treatment capacity could be provided. In 2013, the County selected GHD to assist with analysis of alternatives, project planning, and design. After detailed evaluation, it was determined that the most cost-effective means of providing ENR level treatment for all of the wastewater generated on the Mayo peninsula and to expand capacity to accommodate build-out within the existing service area was to decommission the MWRF and pump the wastewater to a larger treatment facility in Annapolis that was also operated by the County and had already upgraded for ENR performance.The County selected alternative involved construction of a new 24-in diameter, HDPE pipeline to transmit wastewater from the peninsula five miles north to the Annapolis Water Reclamation Facility (AWRF) for ENR treatment. The treated effluent will be discharged through the existing Annapolis WRF outfall into the mouth of the Severn River, which flows to Chesapeake Bay. Once the pipeline is completed, the MWRF will be converted into a regional pumping station and unused existing facilities at the plant will be decommissioned.

With an overall length of about 28,000 ft, the new force main begins at the MWRF, crosses the South River, and extends northward through Quiet Waters Park and the City of Annapolis to the AWRF. For this project, the County requested that the pipe consist of HDPE, which is consistent with its existing pipe infrastructure.

The County elected to install the majority of the force main by horizontal directional drilling (HDD), with the goal of reducing both community impacts, and disturbance commonly associated with open-cut methods. A total of 12 separate HDD bores were designed for the project by GHD, with assistance from trenchless design sub-consultant Brierley Associates. In total, HDD will be used for about 27,000 ft of the force main. This amounts to more than 95 percent of the total force main length.

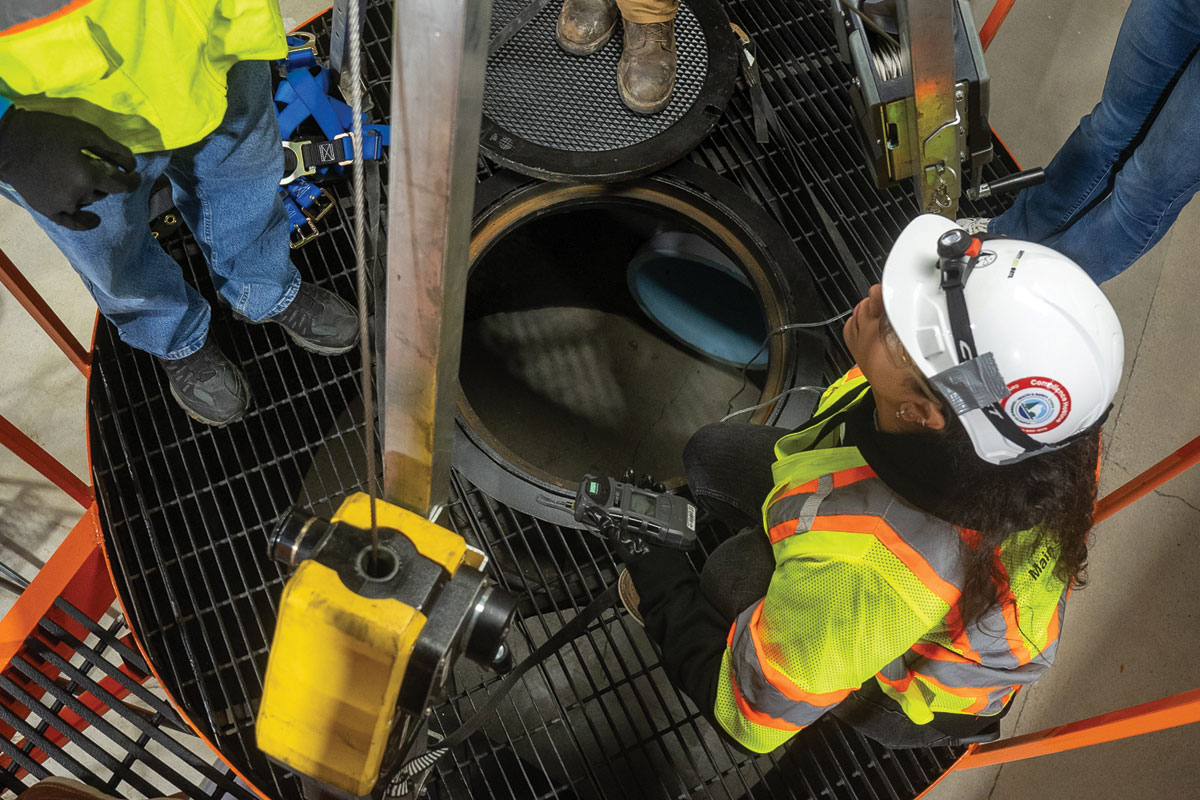

Construction of the pipeline began during September 2015, with a target completion date of December 2016. In order to meet this date, the County decided to split the pipeline construction package into four separate contracts, allowing multiple contractors to operate concurrently. The County also elected to pre-order large quantities of the product pipe to reduce lead time delays. A fifth construction contract was issued for the required modifications at the MWRF and AWRF.

To date, the most challenging contract segment has involved the longest of the HDD bore — the South River Crossing, which extended from Loch Haven Drive to an overlook within Quiet Waters Park. This bore had an overall length of about 4,200 ft, and a compound horizontal and vertical curve required to meet easement requirements.

The subsurface conditions beneath the river include more than 100 ft of alluvial deposits, consisting of very soft silts and clays. These soils are so soft there were problems obtaining samples during completion of the subsurface investigations. As a result of this consistency, geotechnical evaluations conducted during design identified the potential for long-term pipe instability and fluid containment risk. An HDD bore path geometry with a depth of more than 100 ft below the river bottom was developed reduce the risk of frac-out and to minimize the potential for long-term upward pipe movement due to buoyancy.

Any HDD bore path having a length of 4,200 ft and a depth of 100 ft exposes the product pipe to significant loading during pullback installation. These conditions are particularly challenging for HDPE, they push the limits of the pipe strength. To withstand the installation loads, the pipe selected for the South River crossing consisted of 24-in. DIPS DR-7.3 4710 HDPE. Despite this heavy gage pipe, analyses completed for the bore geometry suggested the pullback loads could still exceed the safe pull force of the pipe by 20 to 30 percent.

Another limiting factor associated with the bore length was the limited laydown space at the exit end of the bore. Only 3,100 ft of pipe laydown space was available in Quiet Waters Park to minimize disruption to park staff and patrons. Consequently, the contractor would need to complete the installation in two stages, stopping to fuse two pipe strings together during the pipe pullback

The contractor chosen for the South River crossing contract was Carson Corp. of Lafayette, N.J., which elected to use an American Augers DD-1100 drill capable of 1.1 million lbs of thrust and pullback capacity. A sound barrier surrounded the equipment during all drilling operations to meet residential noise restrictions.

The width of the river and the depth of the bore meant that a walkover line and grade tracking system would be impracticable. Instead, Carson used a ParaTrak wireline system provided by Inrock, equipped with a sensor designed to track downhole annular pressure during drilling. Downhole pressure monitoring combined with a project specific drill fluid design enabled Carson to complete the bore with minimal loss to the adjacent formation, despite the soft softs.

Carson ballasted the pipe with water during pullback to reduce the pull forces, using tremie tubes attached to a water pump. The intent of this process was to obtain neutral pipe buoyancy in the bore, thereby reducing friction between the pipe and the adjacent soils. Above-ground pipe rollers were also effective in reducing drag friction. As a result of these efforts, combined with careful hole preparation, the maximum recorded pullback forces were well below the allowable limits.

Regulatory agencies involved in the project included the Maryland Department of the Environment, the Maryland Department of Natural Resources, the Army Corps of Engineers, the Chesapeake Bay Critical Area Commission, the Soil Conservation District, and Anne Arundel County. The schedule and installation parameters for the pipe installation was driven by permitting agencies, which included limiting construction activities impacting the South River from Oct. 1 to Dec. 15 to minimize the impacts a potential frack-out in the river would have on endemic species. To accomplish this, the Carson worked up to 16-hour days on site and was able to complete the installation at 11:45 p.m. on Dec. 15 without major frac-out or damage to the pipe during the long pull.

Throughout the process, the project team worked closely with the local, state, and federal regulators, residential community activists, park service staff, and commercial watermen impacted by the project.

The total cost for the project is $31.5 million, paid for with a combination of state grants and local county funds.

“This is a long time coming,” Anne Arundel County director of public works Chris Phipps said. “But when all is said and done this is the last piece in the puzzle in our commitment to upgrade all of our sewage treatment plants to meet the enhanced nutrient removal standard and comply with the state mandate.”

Thor Young, P.E., is principal manager at GHD. Nick Strater, P.G., is a trenchless consultant at Brierley Associates