Hybrid Resin of IBG 2K Hybrid-Grouting System Successfully Tested

In theentire first week of April, IBG tested the system in various trials. The hybridresin was grouted in diverse concrete and stoneware pipes of ID 300 and 400 (12and 16 in.). The results of the test series was checked thoroughly by anauthorized expert of SBKS GmbH & Co. KG in Germany. Preliminary results ofviscosity, elastic modulus (E modulus), tensile strength etc. are verysatisfactory. Achieved figures of adhesive tensile strength have to behighlighted as superb. The official approval will follow within the next month.

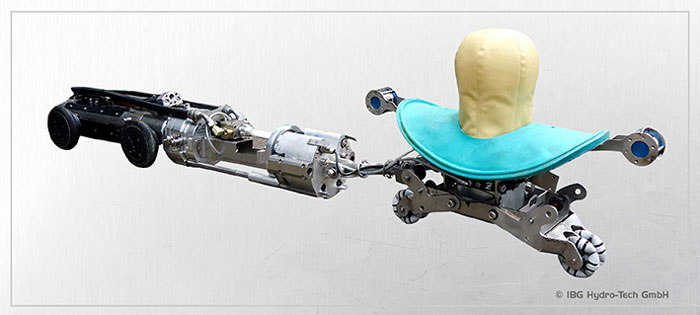

The2K-Hybrid-Grouting-System is a new development that convince the user by itsdiverse advantages. It is a very fast method to rehabilitate lateral pipejoints or to connect laterals with the main sewer after cured-in-placepipelining (CIPP). Complete documentation makes every operation step traceableand ensures reliable work on the jobsite. At the control unit the user can seea schematic of the mixing equipment of the hybrid resin with pumps, storagebasins, valves and different measured values.

Comparedwith current systems on market an increased daily output at comparable inputcan be reached. That means short-time frame procedure at 40 minutes at onehand, generally no refinishing of laterals (no additional sanding of groutingresidues) on the other hand.

The specially developed hybrid resin has superbchemical and physical properties. The adhesive tensile values on the linersurface are up to 400 percent higher than previous types. The system consistsof two 200 liter material tanks. An electronically controlled pump is used tofill and remove the grout components. A 100-m hose is connected with the tanksand supplies the resin to the operating system in the sewer. Just secondsbefore the resin is injected into the lateral the two components are mixed toform the hybrid resin. To ensure a constant temperature of the components atevery time of the year, the tanks and the hose drum are built into anair-conditioned box.

This article was supplied by IBG HydroTech, Büdingen,Germany.