Grout Selection & the Design and Performance of Slip-Liners

The use of slip-liners is now routine to rehabilitate corrugated steel culverts under road and rail embankments that have reached the end of their service lives. Many kinds of slip-liners can be employed, though high density polyethylene (HDPE) pipes are the most common. After inserting the liner, the annulus between the new and old pipes is grouted to complete the repair.

Since the structural response of these liners has received limited investigation, grout selection has been a challenge for consultants designing these projects.

Two common choices exist – Portland cement grout having density about twice that of water and compressive strengths like weak concrete, or an aerated grout having about two-thirds of the volume composed of air bubbles and compressive strength less than 10 percent that of concrete. In addition to its lower cost, an attraction of aerated grout is the greatly reduced buoyancy — contractors must ensure buoyancy does not lift the liner during grouting.

Furthermore, without an understanding of the role of the grout in the load resistance of the rehabilitated structure, it is difficult to make optimal choices between these two very different kinds of grout.

A research program examining grouted slip-liners has recently been completed at Queen’s University, funded by a Strategic Research Grant from the Natural Sciences and Engineering Research Council of Canada. MASc students Caleb Regier, Bryan Simpson and Jake Tetreault, working under the joint supervision of Drs Ian Moore and Neil Hoult, have conducted a series of unique experiments with the goal of answering various questions:

- What is the load capacity of the corroded steel culvert before rehabilitation, and does the corroded steel pipe continue to contribute to the load capacity of the rehabilitated system?

- What interactions occur between the liner, the grout, the old corrugated steel pipe and the surrounding soil?

- What failure mechanisms control the vehicle load capacity of the rehabilitated culvert?

- How does grout choice influence the structural performance, including the failure mechanisms?

- What is the role of the liner in the system during and after rehabilitation, and how does the grout choice influence that role?

- Under what circumstances might high-strength grout be used, and when might low-strength (i.e. aerated) grout be used?

Regier developed a system of impressing electrical current and producing realistic corrosion damage to the corrugated steel pipes, Figure 1. He then measured the strength of a series of corrugated steel culverts having different levels of corrosion-related wall loss, showing that wall loss initially produces little change in vehicle load capacity, but if wall loss leads to significant perforations, it may render the corrugated plate susceptible to local buckling in the vicinity of those perforations.

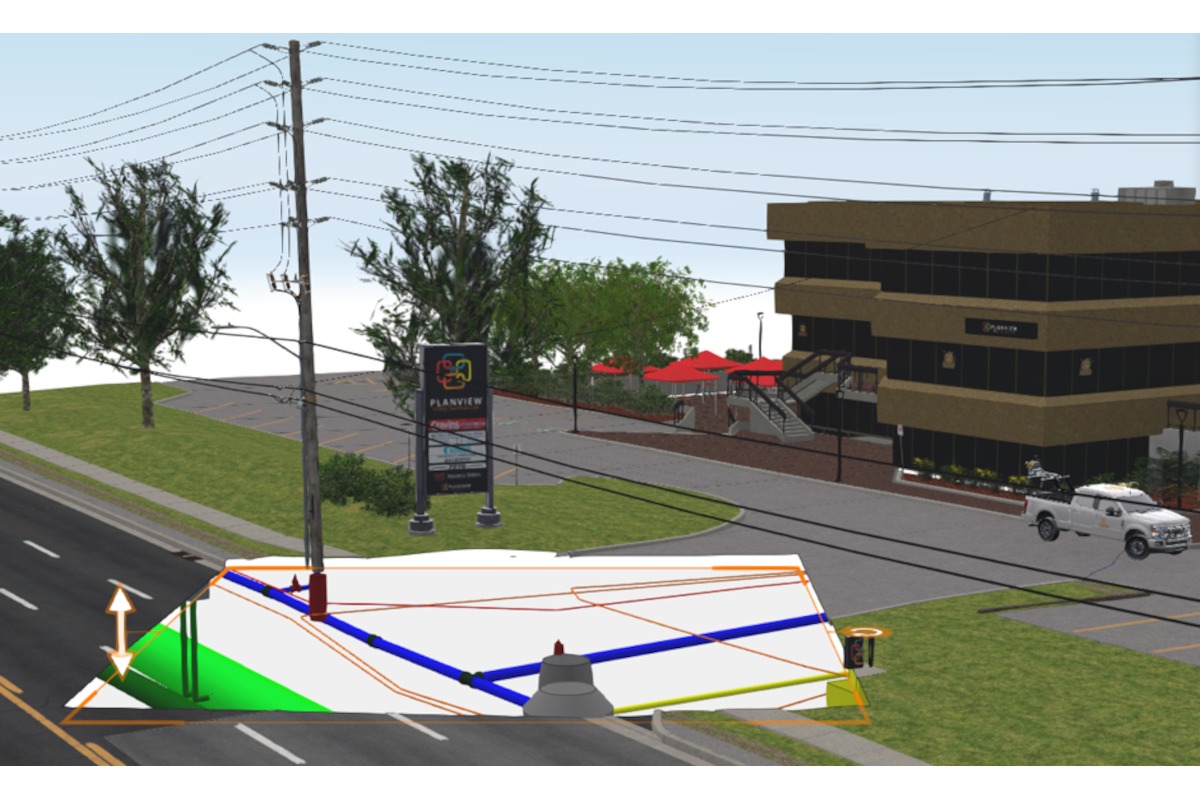

Simpson developed methods of using optical fibers to monitor strains in the corrugated steel pipe, the liner, and the grout, Figure 2. Using Rayleigh backscatter reflectometry, hundreds of very accurate strain readings can be obtained around the circumference of the slip-lined culvert, providing details of the experimental values of hoop forces and bending moments in the liner, the grout and steel pipe. These strains also permit the interactions between the liner and the grout and the grout and the corrugated steel pipe to be explained.

RELATED: Last Word – Value of Industry-University Collaborative Research

Tetreault conducted two comparison experiments – one with aerated, low-strength grout and the second with conventional high-strength grout (otherwise the two test systems were almost identical). This permitted the different vehicle load capacities of the two systems to be measured and compared, and their failure mechanisms to be observed. The low strength grout was seen to behave somewhat like soil, with many shear fractures developing. In contrast, the high-strength grout experienced tensile fractures at the crown, invert and through the cold-joint above the springline (formed because two-stage grouting was used to control buoyancy). Both structures had more than adequate load capacity after rehabilitation, with the corroded steel pipe continuing to contribute to capacity.

While an effective bond formed between the high-strength grout and the corroded steel, bond between intact galvanized steel and grout was weak. Most of the stiffness of the rehabilitated structure came from that high-strength grout (the liner acted as a permanent form). Significant loss of stiffness occurred under vehicle load once bending moments developed in the grout sufficient to induce cracking. Structural design should likely focus on ensuring the high-strength grout does not crack under those moments, and high-strength grout may be a particularly effective choice where loss of stiffness of the corroded culvert has become a concern.

For the low-strength grout, cracking developed at lower loads, and the liner contributed to the overall stiffness and strength of the system. The reduced buoyancy for aerated grout makes construction more efficient, and it is likely a good choice if flexible culvert response remains an effective option after rehabilitation. The liner should then be designed to resist the flexural strains that develop at the strength limit.

The research results have been published in a series of peer reviewed papers (details are available on request).

RELATED: CETT Spearheads Trenchless Research, Education in Western Canada

Note: The author would like to thank NSERC for funding this project, Contech Engineered Systems for providing the corrugated steel pipes, Uponor for supplying the HDPE liners, LaFargeHolcim for supplying the Portland cement, and Euclid Canada for supplying the aeration agent and equipment. Also appreciated is the contribution of Dr. Allan Scott of the University of Canterbury to Mr. Regier’s project.