Designing the Queen Street East Watermain and Forcemain Project

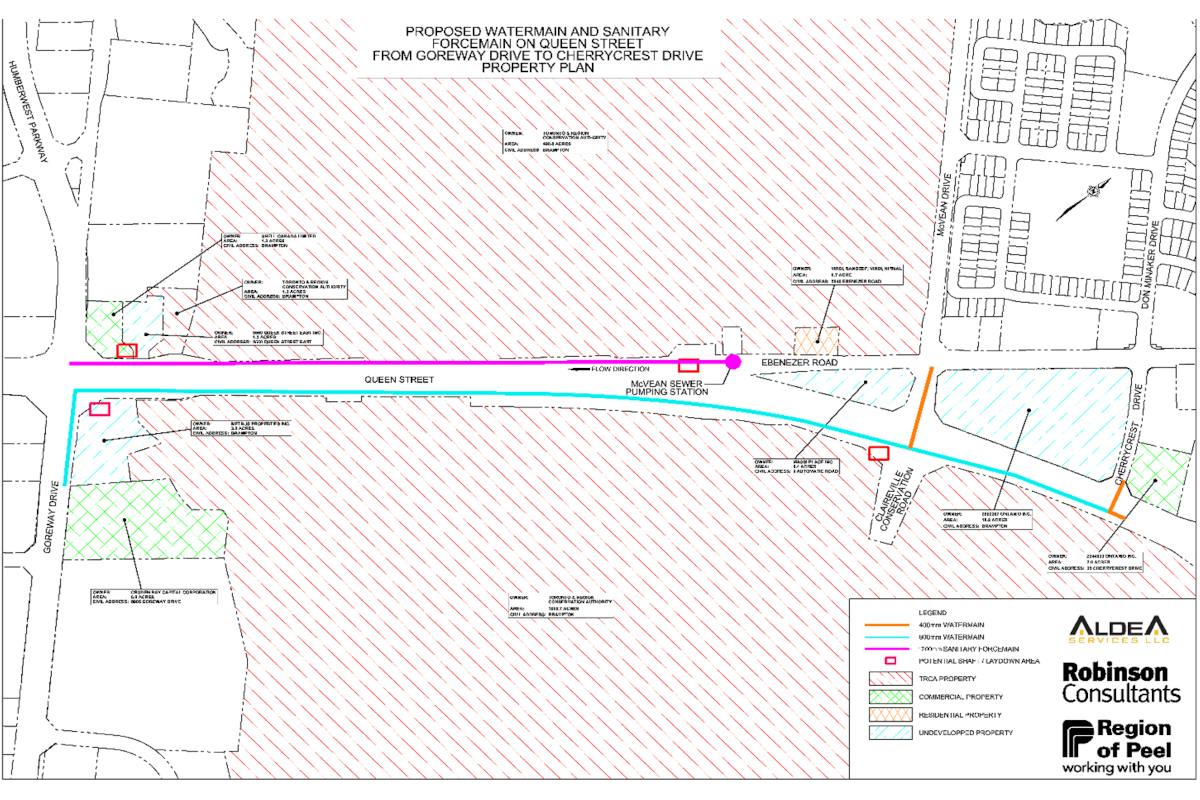

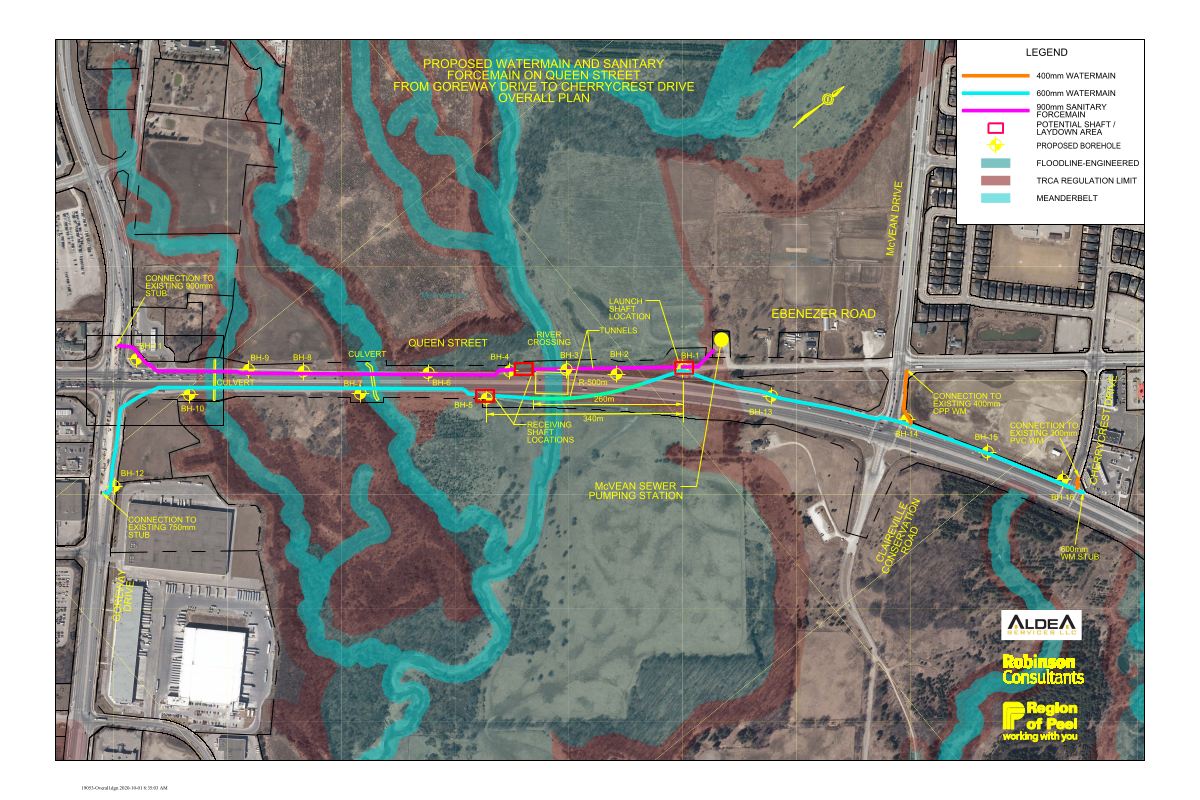

As cities grow, so does the demand for efficient, reliable infrastructure. In Brampton, Ontario, a significant project is underway to meet the needs of the community’s expanding population. The Queen Street East watermain and sanitary forcemain upgrade project spans from Goreway Drive to Cherrycrest Drive.

The project enhances both water and sewer systems to provide more reliable services for years to come. With a focus on innovative engineering and environmental care, this upgrade promises to tackle challenges head-on. It aims to minimize disruptions to both the community and the environment.

A Project with Purpose

The Regional Municipality of Peel recognized that as Brampton continues to grow, its infrastructure must evolve to support this expansion. The Queen Street East project involves replacing and upgrading nearly 1,908 m of watermain and 1,066 m of sanitary forcemain. This includes installing a 600-mm diameter concrete pressure pipe (CPP) watermain and a 1,200 mm diameter CPP forcemain. These upgrades are designed to boost the reliability and capacity of the system. As a result, it becomes ready to handle future demands.

What makes this project particularly complex is its location. It runs near, and beneath, the sensitive West Humber River, home to endangered species like the Redside Dace fish. The project area also lies within a busy traffic corridor, with existing utilities, commercial properties, and regulated conservation lands all nearby. Moreover, the work site sits within a floodplain, adjacent to bridge foundations and roadways that see heavy traffic. These constraints required an exceptional level of planning and coordination to execute successfully.

Innovative Solutions to Environmental Challenges

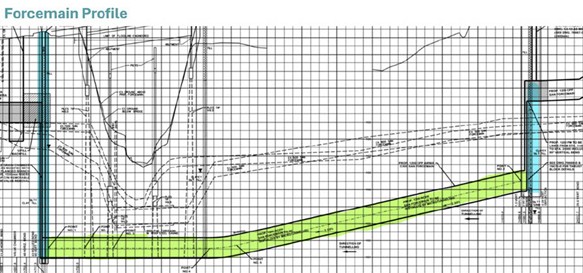

One of the major goals of this project was to minimize its environmental impact, particularly around the river crossings. Traditional open-cut trenching was not feasible because of the environmentally sensitive riverbed and the need to protect the surrounding ecosystems. Therefore, the project team turned to an innovative trenchless solution comprising three-dimensional curved microtunneling (horizontal and vertical curvature). This method allowed the pipelines to be installed beneath the river without disturbing its natural environment.

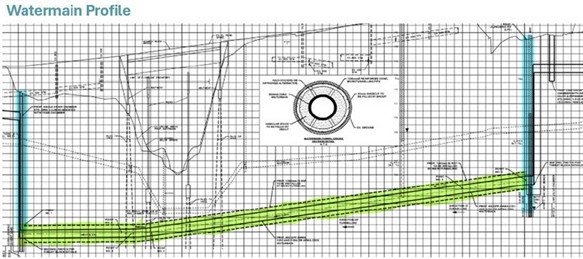

The watermain pipeline was installed using a trenchless drive method over a length of 353 m, employing a two-pass approach. A 1,200-mm diameter reinforced concrete microtunnel jacking pipe was used as the casing pipe. Inside this, a 600-mm diameter AWWA C301 concrete pressure pipe (prestressed concrete cylinder pipe) served as the carrier pipe.

The installation process began with the placement of the reinforced concrete casing pipe. Next, the watermain carrier pipe was inserted within it. After installation, the system was thoroughly inspected and underwent pressure testing. In contrast, the forcemain tunnel utilized a single-pass approach.

The AWWA C300 1,200-mm diameter microtunnel pipe also serves as the final product pipe. Importantly, this approach was chosen due to the lower pressure operational requirements of the forcemain compared to the watermain.

Subsurface Investigations: A Critical Step

Before breaking ground, the team conducted extensive subsurface investigations to assess soil conditions, groundwater levels, and the layout of existing utilities and adjacent bridge foundations. These studies were crucial for determining the precise locations of the tunnel shafts.

They ensured that the pipes would be installed safely and without impacts to existing infrastructure. The findings also led to design changes that avoided nearby utilities in poor condition (structurally compromised). Additionally, they maintained the stability of nearby bridge foundations within a 1.8-m clearance from the pipeline.

Geotechnical assessments and groundwater monitoring further guided the decision to use microtunneling techniques. However, the soil in the area consisted mostly of clayey silt with some cobbles. Thankfully, the precision of microtunneling helped address these challenges. Additionally, a comprehensive geotechnical instrumentation and monitoring program tracked potential surface settlement during construction. As a result, it ensured that nearby structures and utilities were not compromised.

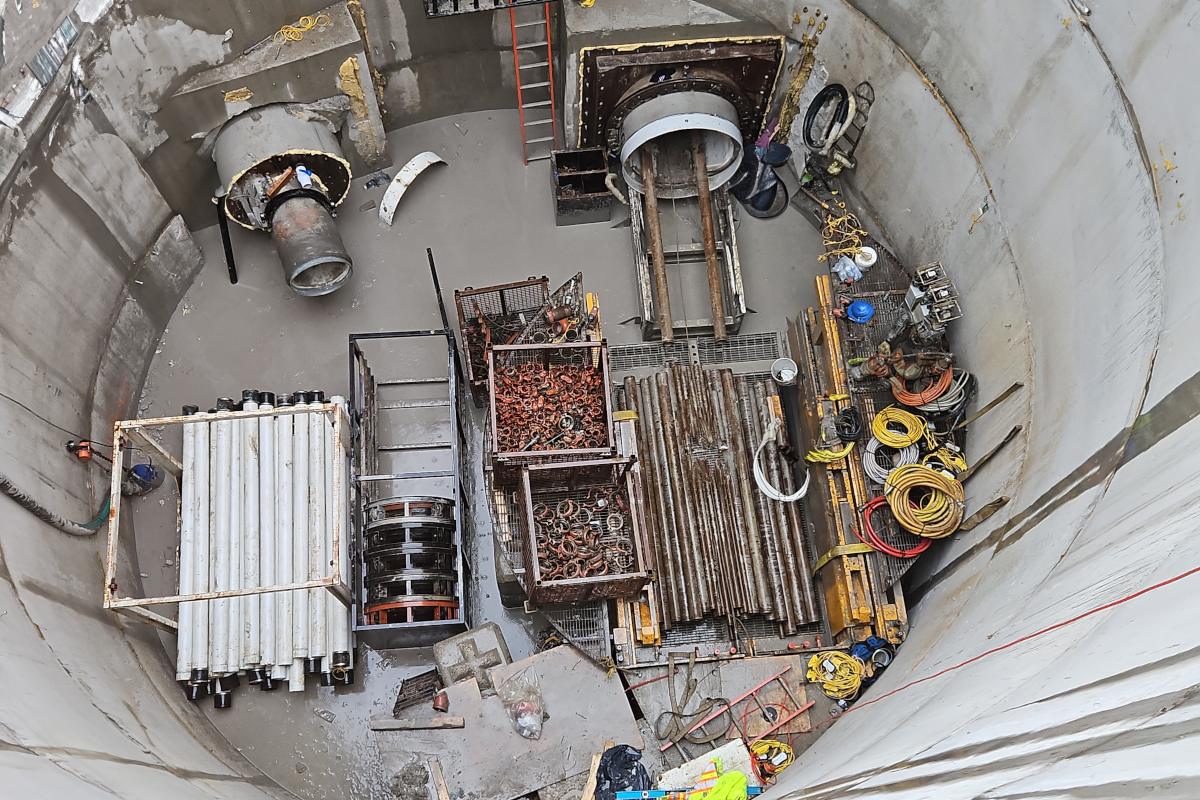

Shaft Construction: A Balancing Act

Another key component of this project was the construction of a common launch shaft and two reception shafts. These shafts, located at both ends of the tunnel drives, serve as the entry and exit points for the MTBM launch and retrieval. The challenge lay in positioning the shafts to avoid existing utilities, such as a nearby 900 mm PVC forcemain. Additionally, they had to avoid impacting the surrounding floodplain.

Various shaft designs were evaluated, ranging from circular to elliptical and rectangular. After careful consideration, the team chose a circular design for its optimal clearance from utilities and ease of construction. The reception shafts also required the incorporation of drain chambers. This involved offsetting the pipes within the shafts to fit the necessary infrastructure.

Queen Street East Key Milestones and Achievements

The project reached several important milestones, with tunneling operations progressing faster than expected. The watermain tunnel was installed over 18 working days, achieving a production rate of approximately 20 m per day.

Meanwhile, the forcemain tunnel was completed in 18 days at a slightly lower pace of approximately 15 m per day. These production rates were achieved through two shifts per day. This strategy allowed the team to meet tight deadlines without compromising safety or quality.

A temporary above-ground HDPE forcemain bypass was also installed to prevent any disruption to the existing sewer system during the construction of the forcemain tunnel.

This bypass connected the pumping station to the downstream open-cut section of the new forcemain. Consequently, it allowed work to continue without interruptions to the flow of wastewater.

Overcoming Unexpected Challenges

No project is without its challenges, and this one was no exception. Midway through construction, the team discovered discrepancies between the location of recorded utilities and their actual positions. Several utilities near the reception shafts were not where the design plans indicated, requiring some adjustments to the shaft locations.

The Queen Street East project also faced a significant delay when a gas main, not documented on as-built drawings, was found to conflict with the proposed open-cut forcemain route. This unexpected conflict resulted in the inability to commission the temporary bypass of the 900-mm PVC forcemain.

onsequently, it delayed construction by approximately four weeks. To address this issue, the contractor proposed a horizontal auger bore (HAB) crossing. This solution allowed the team to pass beneath both the gas main and the forcemain without disturbing the infrastructure above.

Despite these setbacks, the project team’s flexibility and problem-solving skills were key to overcoming these obstacles. Once the gas main conflict was resolved, tunneling resumed smoothly without further issues.

Looking Toward the Future

With Brampton’s population on the rise, the upgraded water and sewer infrastructure along Queen Street East will be crucial for meeting the demands of a growing community. By combining innovative engineering, environmental responsibility, and collaborative teamwork, the project showcases how complex challenges can be met with innovative and cost-effective solutions. As Brampton continues to develop, this infrastructure upgrade will play a critical role in providing reliable water and sewer services to residents. Importantly, it will do so while minimizing impacts on the surrounding environment and communities.

Project Info

- Project Owner: Regional Municipality of Peel

- Engineers: Robinson Consultants Inc. (lead design engineer), Aldea Engineering Services Ltd. (trenchless designer)

- Contractors: FCM Construction Ltd. (general) Erritt Construction Ltd. (tunnelling)

Ethan Zhang, Ph.D, P.Eng., PMP, is trenchless practice lead for Canada at Aldea Services. Joe Linseman, P.Eng., is manager of municipal services at Robinson Consultants.