Designing a Drilling Fluid Program

The One-Size-Fits-All Approach Does Not Exist

From the glacial tills and shales of Western Canada to the Queenston and Georgian Bay formations of southern Ontario, the geology of Canada is expansive and varied. Each requiring a different fluid system to ensure the boring project is a success and there is no one-size-fits-all solution.

Inhibitors, encapsulators and modifiers all playing an important role in the design of a drilling fluid system. The end goal of each system is the same, increase efficiency and keep costs down.

Shales & Clays

Bit balling, mud rings and formation swelling are all problems associated with reactive formations such as shale and clay. When water meets these formations, they begin to hydrate and subsequently swell. As the formation and drilled cuttings swell, they become sticky and viscous. This sticky clay then accretes to the bit and bore wall forming mud rings and clay accumulations. This results in a loss of cutting efficiency, reduction of the annular space and potentially a loss of fluid returns. If not addressed, the annular space can completely seal and a stuck pipe or worse a frac-out event can occur.

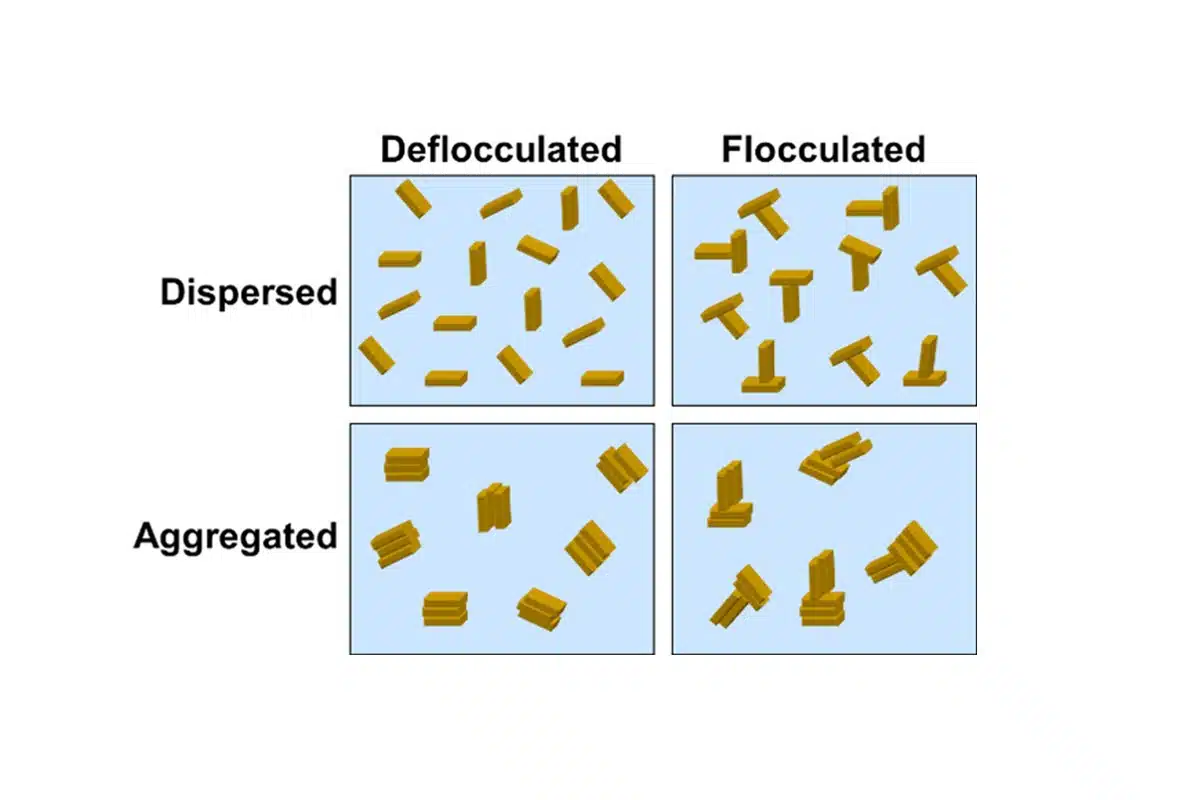

To remedy these problems, inhibitors, thinners and encapsulators are used. Inhibitors stop the problem before it begins, binding to the reactive regions of the clay particles, impeding clay hydration. This results in a form of flocculation occurring at the bit and the clay cuttings can be removed as they are cut.

Additionally, encapsulators can be utilized to “cage” the clay particles and reduce the degree of hydration and cutting agglomeration. The mechanism of encapsulation is similar to that of a spider hunting its prey. It ensnares the clay particles before packaging them up, sequestering them from the rest of the system. Thinners, usually dispersants, break apart the hydrated particles preventing them from generating viscosity and sticking to steel surfaces. They do not inhibit or encapsulate but buy operators time to develop an inhibitive system.

Cobbles can become lodged in casing and equipment.

Sands, Gravels & Silts

On the other end of the spectrum is the unconsolidated sands, gravels and silts. Unlike cohesive clays, these formations are composed of packed individual particles, supported by adjacent particles. As the bore traverses these formations, their support structure, is weakened or removed. This can result in sloughing, hole collapse and fluid loss. The more porous the material the more likely these events are to occur. As fluid is able to enter in between the particles, an increase in pore pressure occurs. This increase destabilizes the formation. When circulation is stopped, pore pressure is lost and the formation collapses.

To make up for the loss of structure and support, fluid loss control and bore stabilizing additives are implemented. These products are usually natural polymers and act both as a bore stabilizer and clay encapsulator where clay is present. These polymers coat the bore wall and cutting face, forming a microscopic mesh structure similar to a chain link fence. This mesh binds together the loose particles causing them to become more cohesive. Bentonite and drill solids then fill the gaps in the mesh forming a barrier (filter cake). This low permeability filter cake reduces fluid migration into the formation and provides a support structure for the formation.

Application Guide and Summary section of an EDFP for crews.

Glacial Till

Glacial till makes up a large portion of surface formations in Canada. Being an amalgam of the two previously mentioned types of geology, glacial till has its own set of challenges. Not only is clay swelling and bore stability a concern, so are the various deposits left by glacial retreat. As the glaciers receded, they left large cobbles and boulders in their wake. Cobbles can become lodged in centralizers, casing, ports and the annular space itself, leading to a multitude of issues.

The solution comes in the form of proper tooling and hole cleaning. The yield point and gel strengths of the fluid are paramount in this regard. Keeping the cuttings in suspension, stops them from settling out and packing off while in the hole.

This is where rheological modifiers such as Star-Plex, an MMS (mixed metal silicate) technology, comes into play. MMS enhances the yield point, low-end rheology and gel strengths of a bentonite system. By increasing the degree of swelling of the bentonite, drastic increases in viscosity can occur without adding a large amount of bentonite. Another benefit of MMS systems is their “gel-locking” ability. MMS enriched fluids exhibit fast gelling times, which can benefit fluid loss control. As the fluid enters into porous formations and moves further away from the high-pressure zones of the bore, it begins to gel and forms a support matrix between the loose particles. This removes any avenue of escape for the fluid in the bore, forcing it to move toward the desired exit.

Pulling line through a glacial till formation.

Oil Sands

Oils sands can be found in northern British Columbia and Alberta. This bitumen rich formation provides some interesting challenges not seen in other parts of Canada. Bitumen resembles tar in appearance and texture.

Although bitumen is a desired resource, it is quite the opposite for the HDD and tunnelling industries as bitumen is more of a contaminant. Bitumen is very tacky, creating tar balls, and accreting to tooling and equipment. To deal with these formations, a specialty emulsifier/encapsulator is used, Tar-Star. By breaking apart the bitumen and packaging up the individual particles in inert envelopes, bitumen can be safely and efficiently removed from the bore without sticking to tooling and solids control equipment (shaker screens).

Bentonite based fluid system.

Engineering a Fluid Program

All of this comes together in the form an Engineered Drilling Fluid Program (EDFP). EDFPs are an integral part of the planning and bidding process. These programs give accurate estimates of the expected fluid volumes, geological conditions and products required. This allows pipeline owners and drilling contractors to prepare accordingly. The geology of the area will determine the composition of the system and method of attack. During the geotechnical analysis, possible problem zones can be identified and contingency plans can be developed. Along with the volume and product estimates, a guide is developed to assist crews with mix ratios, recommended advancement rates and troubleshooting. This all results in a comprehensive plan tailored to the specific requirements of each project.

EDFPs are not just solely for HDD, they are used extensively in tunneling, and even direct pipe applications. Each application will have different requirements and challenges. For instance, tunnelling involves a two-part fluid system (slurry and lubrication). The slurry is pumped to the cutting face of the machine and is designed to inhibit and stabilize the formation while facilitating the removal of cuttings. The lubrication side is designed to mitigate fluid loss, stabilize the formation and lubricate the skin of the machine, thereby reducing the required jacking forces.

Just like how the geologies of Canada are vast and varied, so must be the drilling fluid systems used to conquer them. The goal of every EDFP should be to keep down-time and costs to minimum while providing a simple yet effective fluids system.

The value of a good fluid system comes not only from a cost perspective but also from the time and stress saved by employing the right system for the right job. The trenchless industry depends on successful crossings to support its true purpose. Minimal environmental impact and maximum pipeline life.