D.M. Robichaud — A Leader in the Canadian Sewer Rehab Market

February 16, 2015

Dave Robichaud’s entire 41-year-plus construction career has involved rehabilitating sewer systems in Canada. After 20 years of doing that work for someone else, he decided the time was right for him to call his own shots and take control of his career.By setting out on his own in 1991 to create D.M. Robichaud Associates, Robichaud forged a reputation in the sewer rehabilitation and pipe cleaning industry that is as solid and well respected as any company out there. The Greater Toronto-area business began as bare bones as you could get: with just four people (which includes himself), and a rental van, with and a lot of ambition mixed in.

Today, the 100 percent, full-service trenchless contractor generates an annual revenue of approximately $15 million and has more than 70 workers on its payroll, providing services that include pipe relining and cleaning (small and large diameter and trunk sewer), CCTV inspections, spot repairs, grout-in-place lining for culverts, lateral lining and robotic cutting. The company consistently has a four- to six-month backlog of work.

“We don’t own a backhoe or an excavator. All the work we do is trenchless,” Robichaud says. “We are booked solid right now.”

The company’s wheelhouse of work is in the Greater Toronto Area, which includes the City of Hamilton — recognized as the hub of trenchless work in Canada. But plans to expand its customer base are in the works, with Robichaud and company looking toward the areas of Ottawa and Windsor.

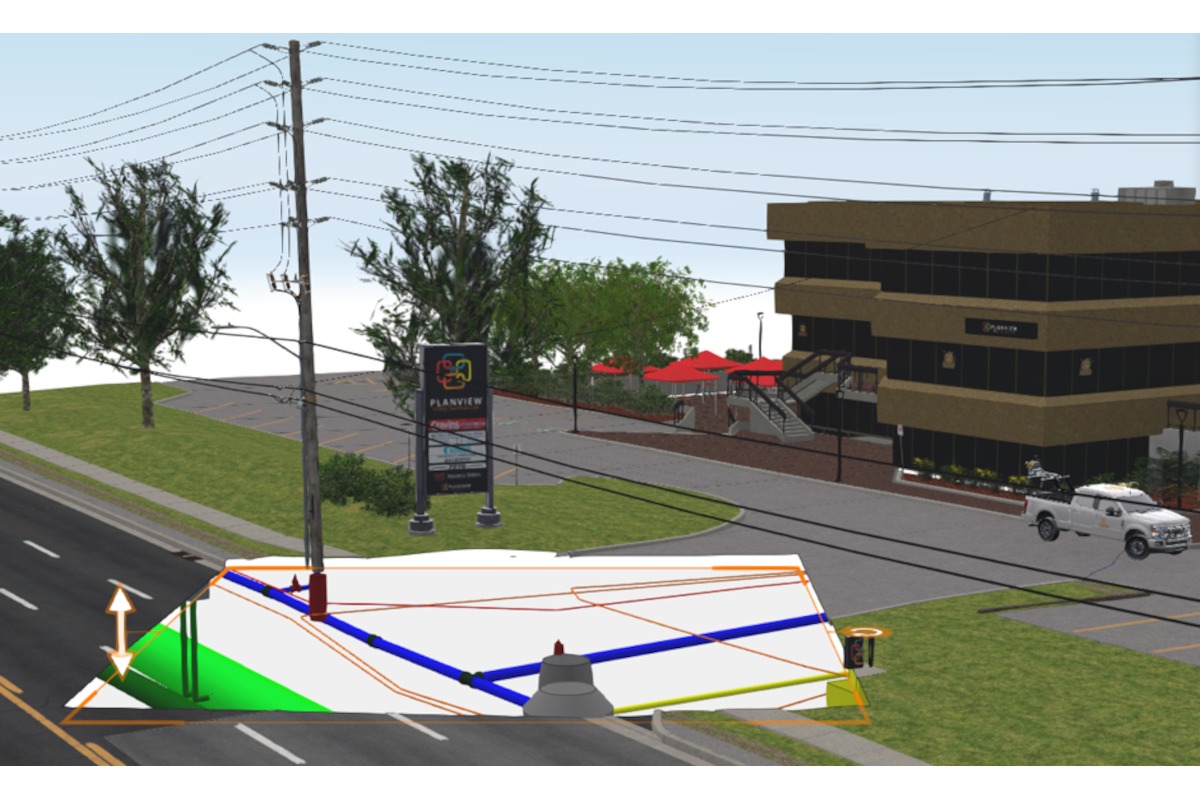

Crews work on an exposed 10-ft diameter sanitary sewer trunk sewer., installing sensors and cameras into the sewer for continuous monitoring during its construction.

A Little History

Dave Robichaud worked for a sewer rehabilitation company for 20 years, serving the trenchless rehabilitation market. But he didn’t care for the way the company was treating him and he decided to leave and work for himself. He knew the trenchless industry well and, in fact, was instrumental in bringing the cured-in-place pipe (CIPP) method to Canada’s underground infrastructure market in the early years via the Insituform method.

“It’s what I knew how to do,” he says. “I started out winching a CCTV camera through pipe and then moved up through companies I was working for, handling different positions. [When I left,] I could have gone into other areas of work but [trenchless] is what I knew and what I liked to do. I had a good reputation and it just made sense.”

Robichaud started out on his own in 1991 with himself, a secretary and two workers. Earl Brousseau joined him soon after and later became secretary-treasurer. Brousseau’s forte was in sales and was successful in finding work for the fledgling company.

“We started with a rental van, renting it by the month for manhole rehabilitation work,” Brousseau says. “That was pretty scary back then. At that stage we weren’t sure how long we would be in business. We started out as a hand-to-mouth operation and that got the ball rolling. Any money we made, we turned it back into investment into the company. We finally bought our own CCTV truck and flusher and started doing regular municipal work.

“From then on it has been careful, proven growth,” Brousseau says.

The company is headquartered in the City of Oshawa, Ontario, and its primary radius of work and customers is 150 miles around the Greater Toronto Area, which encompasses the largest population gathering in Canada. They cater to the municipalities and utility owners and have enjoyed a steady return clientele base.

“We do a blend of things — laterals, mainline and spot repairs, grouting, cleaning and CCTV work,” Robichaud says. “It’s one of the things that make us so successful: We can do everything. We can ride the various ups and downs of the market a little better because we are not focused on one particular item.”

Far removed from the days of that rental van to get around, today D.M. Robichaud has quite a fleet of equipment, including 40 vehicles. The fleet also includes seven Vactor combination units, six Aries and CUES CCTV trucks and IBAK cameras with lateral launch capabilities, three robotic cutters, two water supply trucks, two small flusher trucks and a grout truck. D.M. Robichaud crews include three CIPP lateral lining crews, a CIPP spot repair crew and a lateral launch prep crew. Today, D.M. Robichaud is a licensee for LMK Technologies, using its T-Liners and spot repair products.

The contractor handles all pipe diameters but most of its work is in the 24-in. and under range, which represents about 80 percent of the overall market, Robichaud says. The crews have been doing larger diameter work in recent years and currently are working on a 120-in. diameter cleaning project (should be completed in 2016).

A recently completed project involved cleaning 400 laterals from the main in Markham, Ontario, installing T-Liners in 200 of them. The project was considered to be a “landmark project” in that community and “a first of its kind.” The contractor found that most of the problems with the laterals were at the property line and stopping at the property line with the T-Liner would not fully solve the problems. D.M. Robichaud created a “transition T-Liner” that enabled crews to go through the property line about 3 ft in order to seal the lateral.

“We have come a long way since we first started,” Robichaud says.

A concentrated segment of D.M. Robichaud’s business is pipe cleaning, handling all sizes of pipe. “We clean pipes every day because everything depends on a clean pipe,” Robichaud notes matter-a-factly. “If not cleaning the pipe for rehab, we are cleaning it for inspection. It’s a big part of what we do and probably the most important part. The rehab work can’t proceed without the cleaning.”

Brousseau says a lot of the 48- to 60-in. trunk sewers out there are in dire need of a good cleaning, as they have not been touched in 20 to 40 years, mainly due to the prohibitive costs to municipalities. “The cost to bypass is significant,” he says. “Most of these sewers are in easements, high-traffic areas and utility corridors.”

Robichaud believes so strongly in the importance of pipe cleaning that he and the company have worked tirelessly over the years to get the message out to municipalities through trade articles, conferences and just face-to-face education.

“Many municipalities don’t understand the cleaning process, which makes it difficult for contractors to bid their work,” explains D.M. Robichaud vice president Randy Kowal. “There are all different kinds of cleaning and many municipalities have difficulty breaking down and identifying the scope of work they need properly.”

The company has developed in-house software for its crews to improve project efficiency and cost-effectiveness to better manage its sewer rehab projects — all by using their iPads and eliminating a time-consuming and taxing paper trail.

“We’ve created a digital system for the crews’ iPads, which all the crew trucks have, and create the work orders in the office,” says Kowal. “The iPad allows them access to all the information related to the job — all the videos, reports, project details. They complete the work order on the iPad and it comes right back to the office, allowing it to be processed as soon as the job is done.

“The crews need all that information at their fingertips and it allows us to empower them to make better decisions in the field because they have better information.”

Kowal says the impetus for the technology — which they have been using for about a year — really grew out of the growth of the company. “We’ve grown so much in the last five to 10 years that it’s become very difficult to manage all the information,” he explains.

“Municipalities are getting more sophisticated and are expecting more from contractors. In order to keep up with the expectations, we have to raise our game and catch up to where the clients are.”

The technology also allows for the customer to log in and check on the status of the project, keeping everyone in the loop — something that adds to the company’s bond with its clients.

D.M. Robichaud has a strong and loyal customer base, some going back to the early years of the company. The reason for that loyalty, Brousseau and Robichaud say, is because of the high quality of work they perform and trust they have strengthened over the years.

“We have a loyal customer base,” Robichaud says. “We have had the desire to provide to our client the best product we felt that could be provided by that particular service. If we thought there was a better product out there and we didn’t have it, we’d tell the client that and then we’d go get that product. That’s our philosophy: Give them the best that’s out there. Our success has a lot to do with the trust our customers put in us and in the processes and techniques we use. The customers see that.”

Canadian Trenchless Market

It’s clear that Robichaud and Brousseau enjoy what they do, each full of stories of the early days and how much growth the company and trenchless industry has experienced in the last 20 years. Working together for more than 20 years allows them to reflect on where the industry is at today vs. 40 years ago.

“Even back 20 years ago, Canada was probably the least exposed to the trenchless market,” Robichaud says. “Most of the technologies came over from Europe, which had a dire need due to the concentration of population and piping systems. It came over to the United States next and then slowly filtered up.”

Robichaud explains that he learned of the CIPP technology, as well as the crawler-type cameras and robotic cutters, through his travels. He brought the Insituform CIPP license back to his former company and that market segment exploded. “It was new to Canadians at the time, and we went after it aggressively because we saw the need and value of getting into those markets,” he says.

The issues facing the Canadian underground infrastructure market are no different to those in the United States and elsewhere: funding and education. Robichaud and Brousseau firmly believe that the politicians who control the money need to realize just how important the conditions of the water and sewer lines are to the growth and success of their communities. They believe a lack of education about trenchless technology methods holds them back but the company is committed to changing that.

Robichaud says many municipalities don’t understand the market or the concept of cleaning the larger sewers to remove the calcification and root infiltration. “There’s an expense associated with that to do it properly,” he says. “A lot of them don’t realize how expensive it is to do a job properly and safely.”

As they say: The infrastructure today is crumbling and our industry has got to lobby on its behalf. But like anywhere, out of sight, out of mind. “When it comes to getting funding from the government, we all lobby for that,” Brousseau says. “But sewers aren’t sexy. They’ll spend money on a downtown revitalization and the like but sewers aren’t sexy. That’s the challenge for our industry. Until [a sewer] backs up, they don’t want to look at it.”

Future Plans

D.M. Robichaud officials are more than excited about what the future holds for the company, as the trenchless industry continues to trek in a positive course. They note that trunk sewers will continue to be a larger segment of its work, as municipalities direct some of its infrastructure attention to these pipes.

“In the past, municipalities have ignored all the large pipes and concentrated on the smaller ones,” Kowal says. “That is now switching around. The trunk sewers are the backbone of a municipality. Every year, [trunk sewers] have become more and more of what we do. They are complex and you need special equipment.”

Another area the contractor sees as a growth area is I/I work — meaning the project involves the contractor locating the I/I, developing the plan to fix it and then doing the work. “This type of work is growing in size every year,” Kowal says.

D.M. Robichaud was awarded a contract for the City of Kingston, Ontario with CIVICA Infrastructure. “It’s the first of its kind there,” Kowal says. “It’s an all-encompassing project. They want you to find where the water is coming from, quantify how much water is coming out from each different source and then develop a plan to fix it and do the work. Afterward, a quality assurance-quality control program is to be run to verify and quantify the I/I reduction achieved. It’s a turnkey project.”

“What we see as the best place in the market for us in the future is large diameter work,” Brousseau says. “We are very aggressive about that. The big trunk and transmission lines today have mostly been neglected because of their inaccessibility and safety challenges and are considered high-risk. We are aggressively moving to be a leader in that marketplace.”

Even after 40-plus years, Robichaud still sees the trenchless industry in its infancy in some respects. “There is just so much room for growth,” he says. “There’s so much potential out there.”

Sharon M. Bueno is managing editor of Trenchless Technology.