Microtunneling Optimal Solution for Toronto Sewer Project

November 13, 2015

The replacement of a sanitary sewer along Royal York Road was identified by the City of Toronto as requiring replacement due to poor structural condition of the existing sewer. Project

Project

The scope of this project —part of Toronto’s 2014 Capital Works Program — was the replacement of 165 m of 525 mm sanitary sewer with new 525 mm and 600 mm sanitary sewer along the west embankment of Royal York Road in Toronto, Ontario. The existing sanitary sewer ran under the west embankment, crossing an existing railway bridge behind the west abutment.

The bridge crossing over Royal York Road was constructed by the railway company to provide a grade separation between the rail traffic and vehicular traffic in 1956. Due to the grade separation, the existing sewer was diverted through the west embankment.

RELATED: Toronto’s Massive Push for Underground Infrastructure Tests the Durability of Small Boring Units

Existing Site Condition

The land surrounding the area is a mix of residential and commercial use. The geotechnical borehole data collected identified high groundwater, and Palaeozoic bedrock (shale) was found to be 8 m below ground along the proposed alignment.

The project area is a wooded embankment with residential properties backing onto the construction zone. During design, it was identified that the potential location of the shaft would impede onto a residential property. Therefore, an easement was obtained for these works. Extensive site clearing through the wooded area was required to allow access for all the machinery required to construct the shafts.

As well, a fiber optic cable was found during design to be in-line with the proposed tunneling shaft. It was determined that the fiber would be pulled back during construction and re-instated afterwards.

Proposed Installation

The proposed sewer was installed perpendicular to the railway bridge, with the launching and receiving shafts on either side of the bridge. The proposed invert elevations of the sewer were below the water table. Therefore, a hydrogeological study was performed. The study recommended that a “Permit to Take Water” from the Ministry of Environment, Ontario, was required. The study also recommended microtunnelling as the most feasible option for the sewer installation to reduce possible track settlement due to dewatering and due to the prevalent soil conditions.

Sewer by-pass was required to divert flow because the alignment of the proposed sewer was in conflict with the existing sewer. Sewer by-pass pipes were re-routed through the existing railway underpass and were encased in a metal pipe for protection and prevention of any spillage.

RELATED: Advancing Microtunneling

Open-Cut Installation

Borehole logs from the geotechnical investigation conducted indicated the presence of high water table above the proposed pipe profile. Open-cut installation would require extensive dewatering that would result in adverse track settlements. The railway company would not allow open cut in their travelled pathway. Therefore, open-cut installation was not recommended as an option.

Pipe Ramming

The project location was in close proximity to the residential properties. Also, the existing sewer is located behind the bridge abutment and near the pile/caisson foundation of a Bell Mobility transmission tower. Pipe ramming may impact the existing bridge abutment and foundation of the transmission tower and hence was also not recommended as an alternative.

Horizontal Directional Drilling (HDD)

The grades for the proposed sanitary sewer were governed and restricted by the existing pipe inverts in the upstream and downstream maintenance holes. The proposed sewer grade was to be as low as 0.1 percent or less. The current technology available in the market would not be able to achieve such grades with precision. Also, special exemption approval was needed from the railway authority for use of HDD at the railway crossing. Therefore, construction by HDD was also not recommended as a feasible alternative.

Tunnelling by Jack-and-Bore Method

The proposed sanitary sewer construction was anticipated to be below the groundwater table. Tunnelling by jack-and-bore method would require extensive dewatering. This would increase the risk of settlement near/under the railway tracks along with structural issues for the private dwellings. Therefore, construction by jack-and-bore was also not recommended as a feasible alternative.

Microtunnelling

Microtunnelling using earth pressure equalization methods was employed as recommended in the hydrogeological study report. With this recommendation, extensive dewatering was not required due to static groundwater levels being maintained.

The total length for microtunnelling was 42m using a mixed face cutterhead on the TBM, recommended due to the rapid ravelling or flowing soil type found in this area. Class 140-D, 600-mm ID reinforced concrete microtunnelling pipe was used for the trenchless crossing.

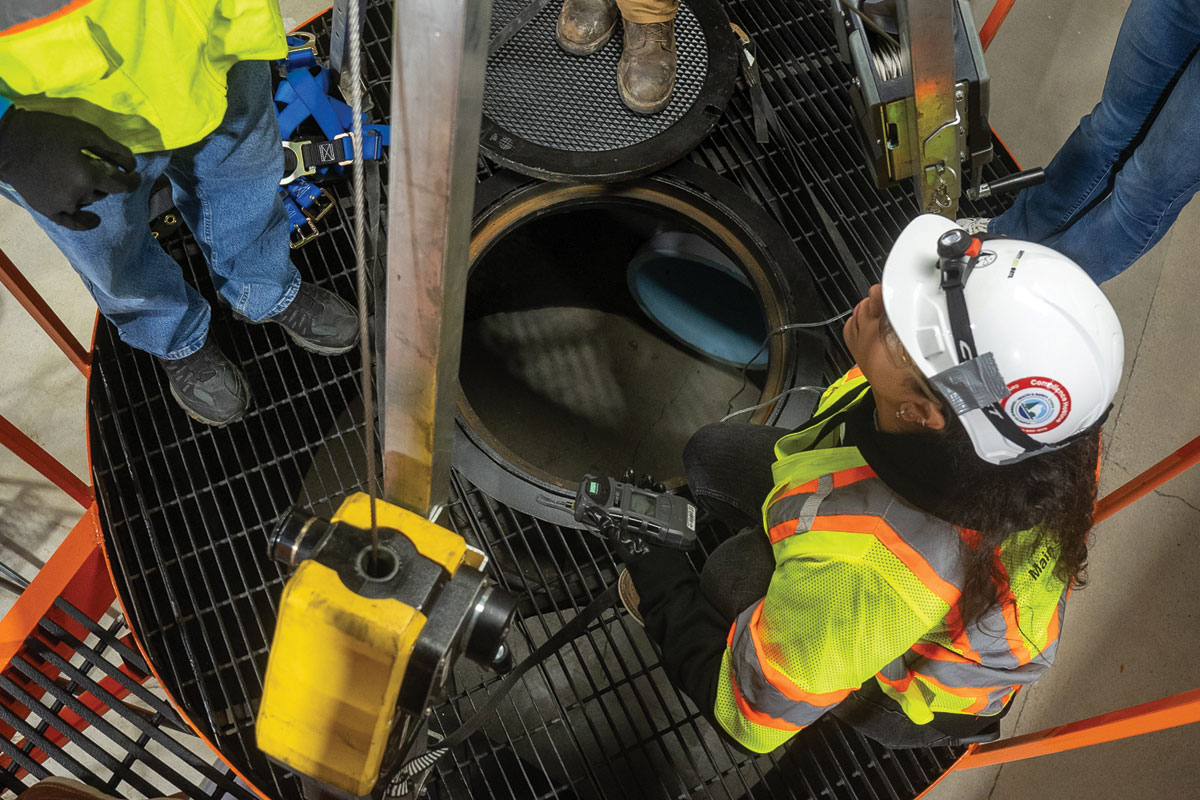

The launch shaft was located at the south end of the project, installing the pipe from the downstream end. A rectangular shaft was constructed of dimensions 4 m by 5 m to a depth of 5 m. The shaft bottom was sealed by a 0.5 m thick concrete slab creating a water tight shaft. Some dewatering was used during the shaft construction.

Due to the proximity, the railway authority required track settlement monitoring. Subsurface monitoring points were installed 1m above the crown of the tunnel bore. Readings were recorded on a continuous basis, and settlements of the voids above the tunnel bore were measured to determine the impact and potential movement of the tracks above.

Ward and Burke used the Herrenknecht Microtunnelling system for this installation. The system consisted of an AVN600 TBM, control container including guidance system, the jacking frame and slurry pumps, settlement tank including water circuit, and Bentonite pumps and high-pressure water pumps.

RELATED: TBMs Dig-in as Saskatoon Continues to be Canada’s Fastest Growing City

The AVN600 TBM provided a closed full face excavation which helped maintain stability in the tunnelling work. Continuous monitoring was carried out to ensure the appropriate jacking force and slurry pressure was applied to maintain the correct stresses. The control container, located next the launch shaft, housed the power pack and electrical equipment to operate the system.

Ward and Burke completed the microtunnelling installation without any untoward issues. The track settlement was found to be insignificant and within the acceptable limits.

Conclusion

Microtunnelling proved to be the optimal solution for the installation of this sewer due to the existing poor soil condition, high groundwater table, and space constraints. The risks associated with conventional open cut, pipe ramming, HDD, jack and bore, including possible track settlement, and adverse impact to the public and private property due to the extensive dewatering required, were too great to consider as a viable solution.

Mai-Linh Ho, E.I.T., and Anton Croos, P.Eng., are with R.V. Anderson Associates Ltd. and focus primarily in the municipal and transportation engineering fields. Bashir Ahmed, P.Eng., is with the City of Toronto – Engineering & Construction Services, and focuses primarily in the municipal engineering field.