Artificial Intelligence & Condition Assessment

Given tight budget constraints and aging infrastructure, municipalities nationwide are striving to finding more efficient solutions to water and sewage management.

Each municipality has its share of sewer pipe challenges, which can wreak havoc for the city officials whose job it is to identify issues, such as root intrusion and structural deterioration, before they become major problems to its residents. However, reevaluating sewer pipeline inspection can be a costly and time-consuming undertaking.

That is why the Town of Newburgh, Indiana, took an innovative approach in restructuring its pipeline inspection process with the help of artificial intelligence (AI).

Mission: Data Control

For any municipality, the pipeline assessment process is time intensive, both during field inspections and in the office to conduct quality assurance/quality control (QA/QC) review. The quality of the data collected is paramount to locating problem areas and forming a plan to address them. The Town of Newburgh Sanitary Sewer Utility officials knew they needed an effective process for assessing the condition of the town’s pipes and their rate of deterioration, both of which includes collecting and storing data, coding video and removing subjectivity from their assessment of data.

Drowning in Data

A significant challenge for Newburgh sewer utility officials was establishing a cohesive system to sort all the data it collected—the department simply needed reliable data in a usable format.

“The Town of Newburgh had thousands of reports and excel sheets with tens of thousands of lines of data, which is far too complex and time-intensive for any individual to wade through,” said Brenton Hasenour, P.E. and project manager, Burgess & Niple (B&N), an engineering and architecture firm. “Even the most qualified and experienced staff would have a difficult time combing through the sheer volume of data.”

Another challenge for the town’s sewer department was the lack of coded video. In the early 2000s, utility owners and contractors throughout the industry adopted the standardization of pipeline observations by the National Association of Sewer Service Companies (NASSCO). The Pipeline Assessment Certification Program (PACP)meant that pipe segments could be compared within the collection system, regardless of location and who conducted the assessment.

Historically, Newburgh had not utilized PACP coding for the condition assessment work. This presented issues when evaluating and comparing pipe segments across the collection system. These issues largely centered around ensuring that a pipe’s condition was accurately captured and errors from human subjectivity and bias when performing the condition assessment. It is important to note that NASSCO coding doesn’t eliminate variances in observations. And that leads to the town’s next challenge.

Subjectivity

Bias, experience level and subjectivity combine to skew observations during sewer inspections. The 30-year veteran inspector and three-year inspector are likely to capture information differently, and that can significantly impact the length of time the camera is in the pipe and the ease of documentation. In addition to varying levels of experience, there will be missed and misidentified codes — it’s only human. Five people can look at the same data and assess a defect five different ways.

The Town of Newburgh is not alone in experiencing these challenges. In fact, sewer pipeline inspection really hasn’t evolved much since closed circuit television (CCTV) started to be used more than 60 years ago. The process is straightforward — a person-operated camera moves down the sewer and captures footage of the sewer’s current state. An individual codes defects based on what can be seen in the inspection video. The final step is the QA/review.

Collectively, these steps often result in the inefficient use of time and money, but there has been a gap in identifying how to make the process more efficient. That’s where AI enters the picture.

AI: Focus on Efficient, Objective and Accurate Inspections

At first glance, one might not think of AI and pipe inspection in the same sentence. In fact, like most municipalities, officials at the Town of Newburgh Sanitary Sewer Utility had never heard of its application in sewer line inspections. They provided approximately 40,000 ft of CCTV to Burgess & Niple (B&N) to complete a condition assessment of its sewer pipe to be processed through its AI system.

B&N’s AI system is designed to save time and money, provide a reliable dataset and have repeatable results. It uses machine learning algorithms paired with computer vision to detect and classify sewer defects. AI provides a subjective and unbiased condition assessment by:

- Coding the same pipe the same way every time, which is critical when comparing two inspections to determine rate of deterioration.

- Providing reliable condition assessment utilizing the most common NASSCO codes

- Allowing field staff to be more efficient by focusing only on cleaning the pipe and capturing quality inspection video

For example, as any municipal sewer line inspector knows, roots can clog sewer lines. Through its AI tool, B&N identifies the location of problems areas. Since problems are repeatable, a utility owner can send crews out on a regular maintenance interval to cut the roots out of the pipes. Additionally, many systems are nearing their useful life and have varying degrees of structural issues, and B&N ‘s system can locate the problem areas.

The AI system processes both perpendicular and longitudinal views, which provide a more detailed analysis while mitigating the chances that defects and other observations will be miscoded or missed altogether.

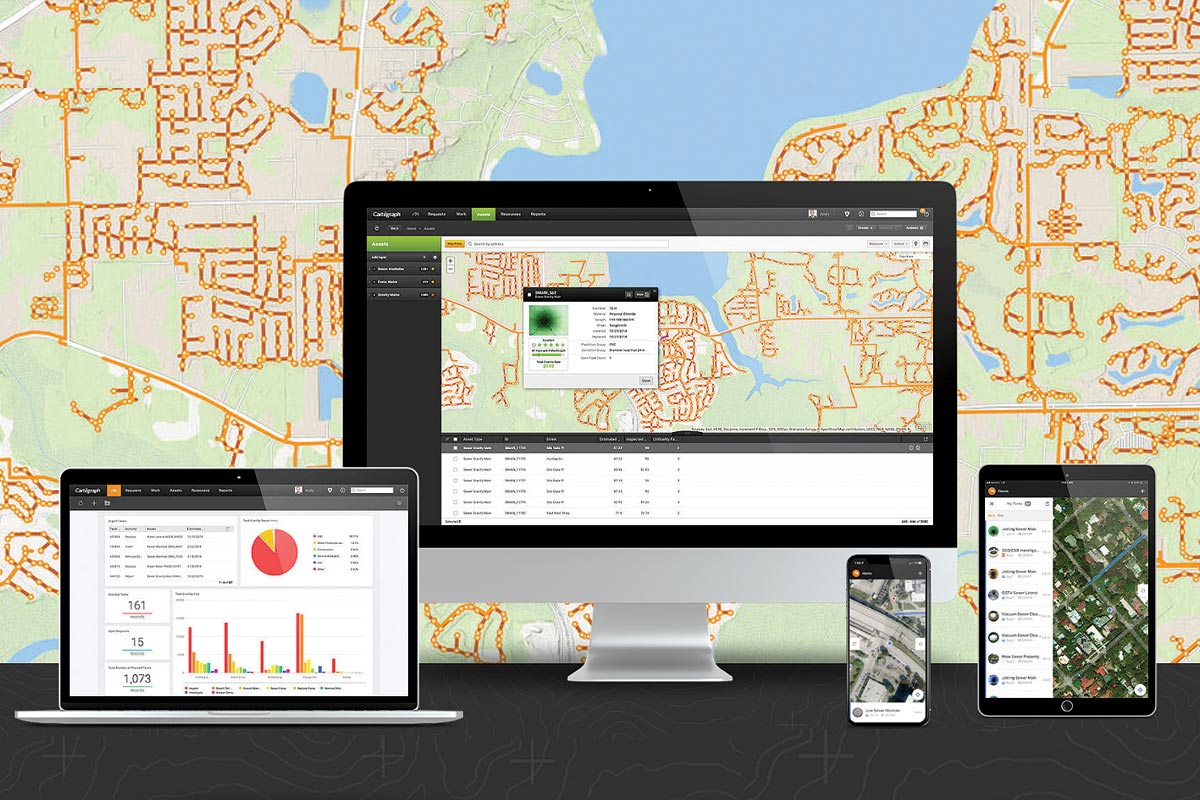

In addition to the traditional reports generated as part of sewer inspection work, town officials wanted to be able to visually see the condition of the system. The AI system has geographic information system (GIS) outputs that can be integrated with a city’s GIS to show:

- Size

- Material

- Date of inspection

- Condition of pipes

- Location of each defect/observation

Helping People Work Smarter

Contrary to popular belief, AI will not replace employee jobs — it helps employees work smarter by having an unbiased tool to reduce errors. B&N’s system provides thousands of photos for each data set and in turn increases AI accuracy.

As time goes on, the AI tool gets smarter because it utilizes a robust dataset of each computer vision model that is continuously supplemented with inspection data through a supervised learning environment that increases its accuracy over time. As the program gains a deeper understanding of what each defect looks like, it reduces the time required for reviewing sewer inspection data.

Another bonus is that it is designed to fit in with an industry typical workflow when inspecting pipes. Therefore, staff does not need additional training and can perform work how they have always done it, also bringing value to existing inspection data.

Results: Streamlined, Smarter Sewer Inspections

Looking ahead, the Town of Newburgh can have a higher degree of certainty that incident codes are identified correctly. Sewer inspection officials have already noted a difference.

“Newburgh Sanitary Sewer Utility gave us CCTV data from five to 10 years ago, said Hasenour. “Using data of the same pipe from the past year, we were able to make comparisons to determine their rate of deterioration. B&N’s AI system enables the town to spend money on the most problematic areas, which is far more efficient.”

The system can also be used as a reporting tool, demonstrating to the town council how money is being spent. For instance: some pipe’s condition showed improvement between the video taken five to 10 years ago and the recent video. When investigating these instances, it was found that these pipes had received point repairs which removed the defects and improved the condition of the pipe. This documentation was used to show officials the progress made by the utility’s past efforts.

“Having the ability to see these comparisons really gives us a sharper view on deterioration and location,” said Sewer Commissioner Steve Shoemaker. “Based on the initial reports provided through the AI system, we can more accurately predict costs to include in the city’s annual budget.”

The Town of Newburgh’s Sanitary Sewer Utility is considering long-term plans to incorporate B&N’s AI system into their institutional program.

“This AI system is taking our sewer pipe assessment program to the next level, and we look forward to a far more efficient and cost-effective sewer inspection process,” said Shoemaker. “By using the CCTV data that we’re already gathering and translating it into a more useful format, it’s making the utility’s efforts more valuable, providing a high level of service to our customers.”

Brenton Hasenour, P.E., is a project manager and Josh Ford, P.E., is a project engineer at Burgess & Niple.