Tech Forum – 3D GPR Arrays: A Robust Tool Reducing the Level of Uncertainty in the Subsurface

The horizontal directional drilling (HDD) industry is versed in the tools to help minimize the risk of conflicts in the subsurface and several tech platforms have evolved in ways unimaginable just a few years ago.

The overall goal in any subsurface mapping project whether the cursory compliant call to 811 or a full subsurface utility engineering (SUE) investigation seeks to decrease the level of uncertainty of what is below. HDD conflicts can range from a nuisance to a full-blown catastrophe depending on the conflict encountered. Either way, there is a cost.

A powerful resource that explores conflicts from all sources of underground excavation is published annually by the Common Ground Alliance. The CGA report, Damage Information and Reporting Tool appropriately referred to as the DIRT Report compiles reports of damages from participating stakeholders nationally. DIRT’s field form allows a user to select one root cause for each submitted damage. The findings in the report are very detailed however the report summary outlines the top five root causes for the year. These top five account for nearly 70 percent of damage events for the reporting year.

Noted in this top five was a failure to notify the One Call center/811 and this remains the largest individual root cause year over year. Most relevant perhaps to HDD is that the excavator dug prior to verifying marks by test-hole (pothole) combined with the failure to maintain clearance from an underground facility. This is the most prevalent and consistent cause of damage due to the excavator. Regarding activity to detect and designate/mark utilities, abandoned facilities and locator error combined make up the majority of locating issues likely contributing to the failure to maintain clearance.

What is interesting is how often abandoned facilities impact the certainty of locates. Of the total errors reported in the report (CGA DIRT Report 2020, Vol. 17) from locator activity, 26 percent of the total reported were attributed to abandoned facilities. As well, the report cited locator error at 38 percent. This is testimony that we need to involve as many tools as is necessary to reduce these numbers.

Locating will always involve a level of uncertainty as to what is actually detected from any detection tool whether EM, GPR or other.

In the SUE profession, managing uncertainty is defined by quality levels from QL-D to QL-A. It should be noted that even QL-A does not guarantee zero uncertainty. An abandoned line can often exactly mimic the one you are looking for and the active line could be close by but simply missed. Anyone involved in underground mapping as a deliverable knows that even with QL-A expect the unexpected.

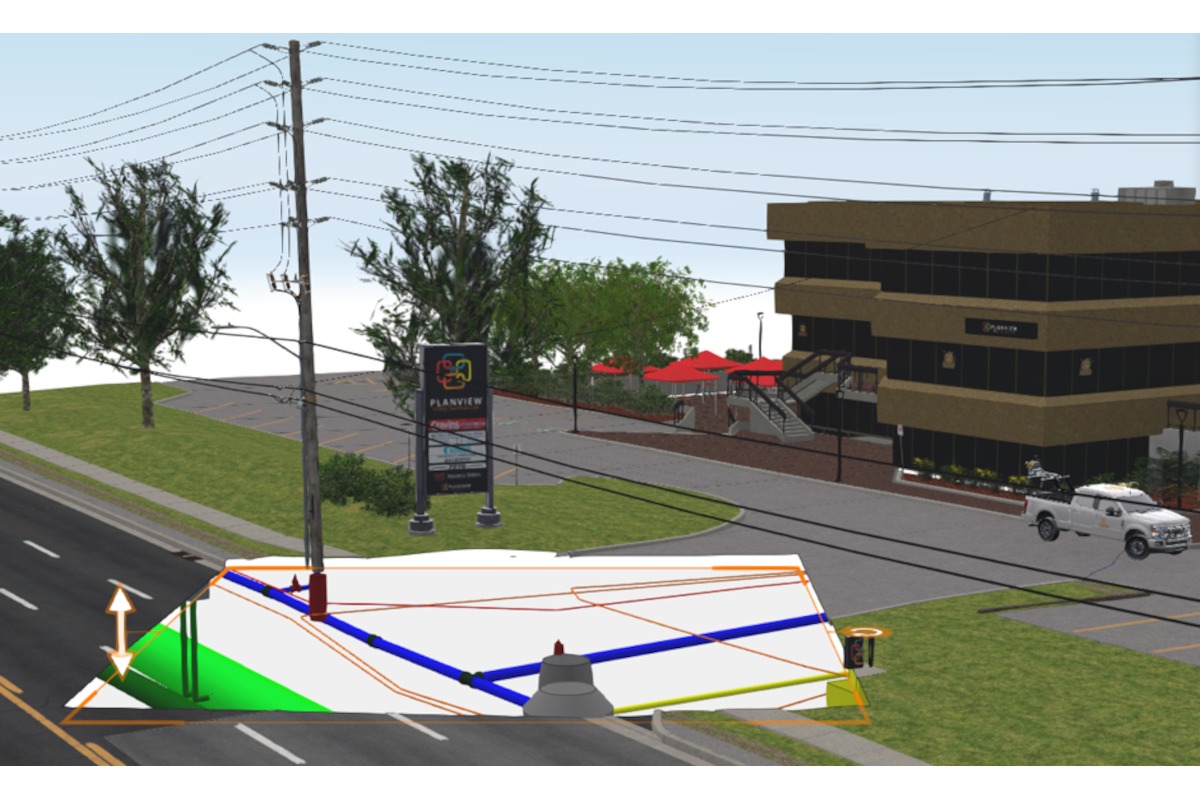

One of the most recent advancements in geophysical methods involves GPR array systems for large-scale or highly complex SUE or subsurface utility mapping investigations. The new generation arrays — as with any reasonably new entrant of technology not yet universally integrated into the damage prevention industry — are gaining traction and for good reason. Arrays are now capable of mapping a street corridor at posted speed limits and processing of the data is now streamlined and simplified so that it does not take a unique specialist to learn but rather engineers, geomatics/survey professionals and other technical personnel can perform this function. The images obtained by an array in favorable GPR conditions approach that of an MRI of the underground. Figure 2 is data from a project in Spokane, Washington.

The OspreyView image depicts all utilities detected with the array from the surface to the detection limit of the GPR array — in this case approximately 9 ft. The colors indicate the depth in the 3D image for easier visual interpretation with manholes and near-surface features in yellow gradually becoming blue for the deepest utilities. The representation is in 3D so a technician can in fact pick these utilities and export the line data directly into CAD. Or in some cases the data is exported as a GeoTIFF directly into CAD and used as a layer as with other corroborating data from the project e.g., EM data.

The revised standard this year for SUE investigations — ASCE 38-22 — incorporates the use of MCGPR or GPR arrays. ASCE 38-22, Standard Guideline for Investigating and Documenting Existing Utilities, provides guidance on treating 3D data for the final deliverable. Interesting and relevant to all stakeholders, including HDD professionals is the inclusion of vault dimensions, other conflicts such as thrust blocks, buried foundations and any other feature that would constitute a potential conflict at excavation or boring.

Circling back, the DIRT report also states that, “there may be damages related to mapping, tracer wire and abandoned facility hidden in the Locator Error category. Therefore, such errors should not always be interpreted to conclude that the locate technician is the responsible party. Inaccurate maps, broken tracer wire, abandoned facility, etc. could lead to an inaccurate locate even if the locator followed all proper procedures.”

There is nothing more compelling than a real-life illustration of not only the value of 3D imaging but also how the 3D Raptor image potentially helped resolve the very issue with tracer wire cited in the DIRT report.

Safe Site Utility Services LLC, a Glendale, Arizona-based company, provides advanced subsurface utility mapping services throughout the southwestern United States. According to Ryan Bradley, SUE division manager, the Raptor array system is a powerful tool, particularly in the challenging soils of Arizona. A recent project along a congested corridor proves the value of using a dense GPR array.

“The Raptor array often identifies unknown utilities along just about every corridor we map” states Bradley. In one of Safe Site’s most recent projects it not only mapped several unknowns but also believe a gas line mapped with EM followed the tracer wire/tape and not the actual facility.

Figure 3 is a portion of the CAD drawing for the corridor incorporating QL-D-QL-B information. Unknown utilities are marked in black detected with the array. The gas line as mapped with EM seems to take a different path than what was detected with the Raptor array.

Processing the Raptor data in Condor Processing software and displaying in OsperyView (Figure 4) clearly shows a utility path differing from what the EM locator mapped.

Within this same project, several other unknown utilities were identified with the Raptor array. Could these be abandoned lines that contribute to the 26 percent of mislocates cited in the DIRT report? One would have to conclude-yes. The report provided by Safesite hits both marks in the DIRT 2020 report — tracer alignments not following reality and detection of unknowns likely abandoned. The beautiful thing about this investigation is at the very least, the HDD contractor or excavator whatever the case may be, will not hit these marks and contribute to that statistic!

Matthew J. Wolf is the president, ImpulseRadar USA Inc.