Why Lateral Rehabilitation Matters

10 Reasons to Injection Grout Your Leaking Laterals

Laterals are often an overlooked source of infiltration and inflow (I&I). However, they are consistently identified as a leading cause of infiltration into collection systems. Industry reports from the U.S. Environmental Protection Agency (EPA) and the Water Environment Federation (WEF) have highlighted main-to-lateral connections. These are some of the most common paths for infiltration, with much of it coming from private service laterals (more on that later).

According to the EPA, up to 60 percent of sewer overflow comes from leaking service connections. In some systems with aging infrastructure, laterals and their connections can contribute as much as 70 percent of I&I. This amount of infiltration has wide-ranging impacts: it consumes collection system capacity, accelerates pipe deterioration, increases the frequency of sanitary sewer overflows (SSOs), and overloads treatment plants with millions of gallons of clean water. Ultimately, this drives up operational costs that are consumed by ratepayers like you and me.

Lateral Challenges – Who Is Responsible?

Besides the unique technical challenges involved with lateral rehabilitation in and of itself, there are also questions of ownership, responsibility, and funding that create headaches and confusion. In most cases, the city owns and maintains the sewer main, but the home or property owner is responsible for the entire length of the lateral, often from the building to its connection with the mainline. This creates complex maintenance responsibilities that can be overlooked by owners. This often leads to neglect and, in turn, a major source of unchecked I&I.

There are cities that may take ownership or claim a portion of the lateral that lies in the public right of way – such as under the street to the curb. Some cities even claim the entire lateral or have developed financial assistance to help property owners with the costly repairs.

Regardless of responsibility or ownership, evidence is clear: repairing mainlines alone – while beneficial – only scratches the surface of I&I. Case studies show that unless laterals are included, I&I reduction can fall short of its full potential. For bigger impact, municipalities and homeowners alike must take a holistic approach to rehabilitation—one that includes laterals as a critical part of the system. So, how do we get there?

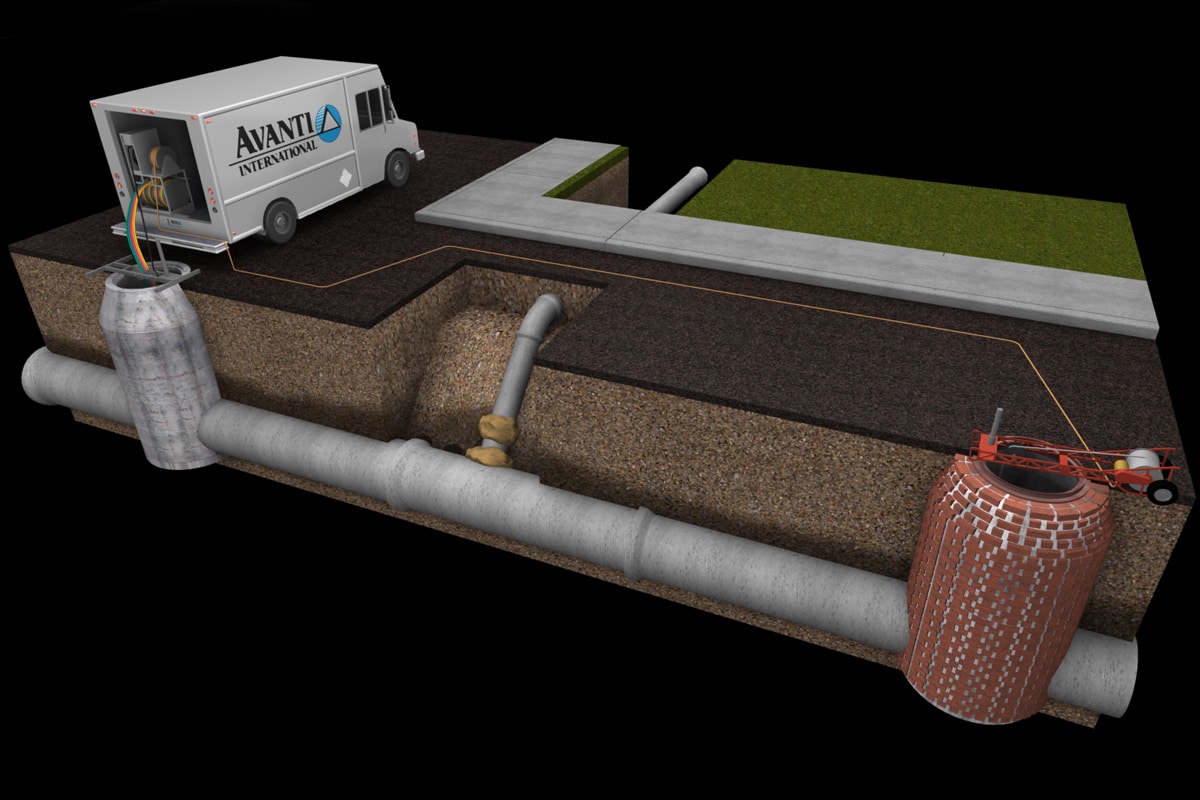

Trenchless Technology for Infiltration Control in Laterals: Injection Grouting

Injection grouting is an advanced trenchless technology. It is designed for infiltration control and stabilizing soils around underground infrastructure. For laterals that are in good structural shape but suffer from leaks at joints, cracks, or defects, injection grouting is an excellent solution for your infiltration woes.

Why should you injection grout for infiltration control? Here are 10 reasons:

1 – Directly Stops Infiltration/Exfiltration at the Source

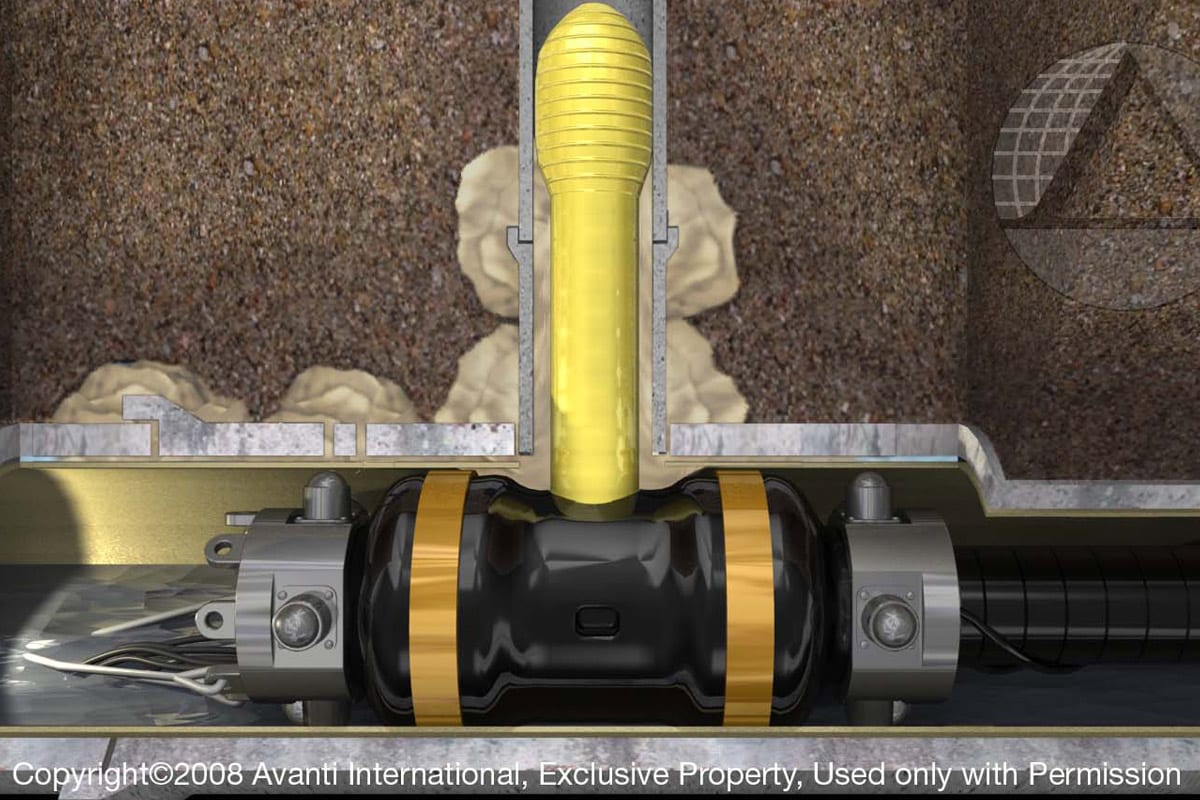

Grout is injected under pressure through leaking joints or defects. As it penetrates the soils outside the pipe, it creates a gel/soil matrix and waterproof barrier. Grouting creates a long-lasting seal within the soil that eliminates groundwater entry.

2 – Cost-Effective to the Budget

Grouting can have a lower upfront cost and smaller jobsite footprint than lining or other trenchless rehabilitation methods. The all in cost comparison between grouting and lining laterals for infiltration control often shows grouting to be 10 to 30 percent of the cost of lining. There are always project specific factors that could affect this.

3 – Preserves Pipe Capacity

The real work of the grout happens outside the lateral where it cures with the soil. There is no reduction in the pipe’s inside diameter which is extremely important when working with smaller diameter pipes. Every bit of capacity matters! The grout left in the pipe is called residual grout, is harmless to the system, and will eventually flake off and head for the treatment plant.

4 – Strengthens/Stabilizes Soils Around Lateral

As stated above, the real impact happens outside the structure. As grout penetrates the surrounding soil, it cures with soil fines, fills voids, and helps restore soil stability around the lateral. This helps re-establish support for the pipe and reduces the risk of future settlement or movement. Note: While injection grouting is not considered a structural repair, it does provide added strength and stability to the overall system.

5 – Targeted Application

Grout can be injected only where needed such as specific joints, defects or service connections. This makes it a great solution for spot repairs without disrupting the whole system or relining an entire lateral. Lateral grouting equipment can reach from just a few feet up the lateral to more than 30 feet!

6 – Compatible with Other Trenchless Methods

Grouting is a great solution on its own but can have limitations as it’s non-structural. Grouting works in conjunction with many trenchless methods such as linings or coatings. For example, you can grout first to stop active infiltration and stabilize the soil before installing a liner to help ensure long-term liner performance by preventing washout or annular space infiltration. Grouting can also be injected after lateral reinstatement to stop leaks at the connection and in the annular space between host pipe and liner.

7 – Proven Longevity

Grouting is a proven technology that has been successfully used for decades in mainlines, manholes, and laterals for infiltration control. It continues to evolve with modern grout formulations and delivery systems. The first mainline was grouted with acrylamide back in the 1960s. There’s even third-party testing by the Department of Energy that gives acrylamide grout a 362-year half-life in the soil.

8 – Environmentally Friendly

Grouting helps protect our communities by preventing groundwater with possible contaminants from entering the collection system. It also stops wastewater from exfiltrating into the surrounding soil. Many grouts even have third-party testing by entities such as the Water Quality Association (WQA) to be NSF/ANSI/CAN 61certified for drinking water system components. Once cured, injection grout is inert and non-toxic.

9 – Minimal Disruption

Injection grouting is 100 percent trenchless and allows for quick access points through manholes and an overall quieter installation. There’s little to no impact on property owners since no excavation is needed, and jobsite footprints can be easily maintained. Packer equipment is often designed as flow-through so bypass pumping is unnecessary.

10 – Time to Complete

Injection grouts cure or gel quickly – from seconds to minutes. With its minimal setup, near immediate results, and efficiency compared to other trenchless or dig-and-replace methods, crews can complete several laterals per day.

In the end, tackling I&I in laterals (and mainlines!) is essential for controlling treatment costs and reducing the risk of overflows. It also helps in building long-term system resilience to our aging infrastructure.

Among the available trenchless solutions, injection grouting stands out as a direct, economical, and least disruptive option for stopping infiltration in laterals — whether used on its own or in combination with structural trenchless methods.

Jessica Williams is marketing manager with Avanti International.

- Puris, Per Aarsleff Partner to Strengthen Lateral Rehab in Canada

- Vortex Companies Rebrands Grout Line to Maverick Grouts

- Vermeer Unveils VXT400, VXT500 Vacuum Excavators

- How to Reestablish Service Connections After In-Building CIPP Rehab

- How to Handle Dealing with a Railroad on Your Project

Next Up

2026 CUIIC Academy Spring Summit | March 3-5, 2026 | Mississauga, Ontario | Learn more