The Safety Advantages of Using Hydro Excavation on HDD Jobsites

Compared to traditional digging techniques, hydro excavation offers a range of safety advantages. This makes it the ideal choice for supporting HDD operations.

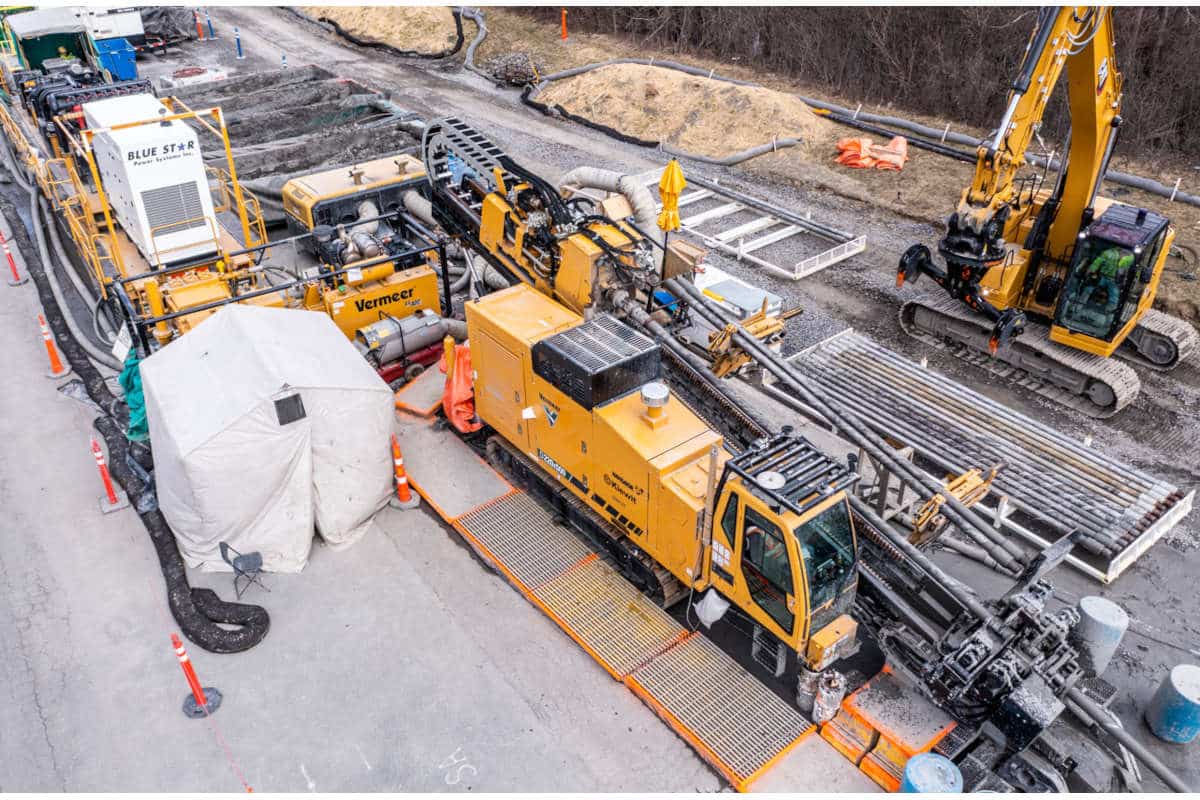

Horizontal directional drilling (HDD) is a widely used trenchless technology. It installs underground pipelines, conduits, and cables with minimal surface disruption. While the method itself offers several environmental and operational benefits, safety remains a top concern. This is especially true when working around live utilities.

This is where hydro excavation emerges as a critical complementary method. It significantly enhances the safety and efficiency of HDD jobsites.

Hydro excavation uses high-pressure water to break up soil and a powerful vacuum to remove the slurry. As a result, it leaves behind a clean, precisely dug hole or trench.

These advantages include safer work around live utilities, minimized restoration efforts, and reduced manual labor. Additionally, it lowers contractor liability associated with damaging unmarked or misidentified underground infrastructure.

1 – Safety Around Live Utilities

One of the most pressing dangers on HDD jobsites is the risk of striking live utilities. These utilities include gas lines, electrical cables, fiber optics, or water mains. These incidents can lead to service outages, environmental hazards, injuries and, in severe cases, fatalities. Traditional excavation methods, such as backhoes or even hand digging, carry a high risk of accidentally damaging these utilities. This risk is especially high when maps are outdated or when utility markings are inaccurate.

Hydro excavation significantly reduces these risks. The use of pressurized water and suction allows for precise and non-destructive exposure of underground infrastructure. Unlike mechanical tools that can inadvertently slice through cables or puncture pipes, hydro excavation gently uncovers utilities without direct contact. This makes it an essential tool for potholing or daylighting. Here, utilities must be positively identified before directional drilling begins.

This precision not only protects workers onsite but also ensures the continuity of utility services in the surrounding area. This consideration is especially important in urban environments or around critical infrastructure like hospitals, schools, or data centers.

2 – Minimal Restoration Required

HDD is already praised for reducing surface disruption compared to open-cut trenching. Hydro excavation supports this goal by further minimizing the environmental and structural impact of the job. Because it is highly targeted and accurate, hydro excavation creates smaller, cleaner holes. This translates into less damage to landscaping, sidewalks and roadways.

Minimal restoration requirements mean safer job sites in multiple ways. For example, less backfilling reduces the likelihood of surface instability or subsidence post-installation. It also minimizes the need for heavy machinery that could introduce new hazards, like equipment collisions or ground collapse. Moreover, when jobsites are neater and less intrusive, there’s reduced risk to the general public and nearby pedestrian traffic. Thus, it enhances overall site safety and community satisfaction.

3 – Reduced Labor and Risk from Hand Digging

Hand digging has traditionally been used to carefully expose utilities or verify clearances during HDD operations. However, it is labor-intensive, time-consuming, and physically taxing. From a safety perspective, hand digging poses risks such as repetitive strain injuries, fatigue, and inadvertent contact with energized lines. This is especially true when performed in difficult or compacted soils.

Hydro excavation significantly reduces the need for manual digging. With the ability to safely excavate through hard-packed soil, frozen ground, or clay, it dramatically decreases the amount of physical labor required. Workers are less exposed to common trenching hazards like cave-ins or tool-related injuries. Overall ergonomic strain is minimized.

By shifting the burden from manual labor to machine-assisted digging, hydro excavation improves safety outcomes. It helps keep projects on schedule, even in challenging ground conditions.

4 – Reducing Contractor Liability from Hitting Unmarked Utilities

Despite strict regulations and best practices such as calling 811 for utility locates before digging, underground utilities are not always accurately marked. Errors in mapping, outdated records, or the absence of precise GPS data can result in mislocated or completely unmarked utilities. When these are struck — intentionally or accidentally — the financial and legal consequences can be severe.

Contractors may face hefty fines, liability for repairs, lost revenue claims, and even lawsuits. Beyond financial exposure, there are reputational risks and potential damage to long-standing client relationships.

Hydro excavation helps contractors mitigate these liabilities. Because it allows for safe exposure of underground infrastructure before HDD installation, it adds a layer of verification. This goes beyond standard utility locate practices. By exposing utilities in real-time and in their actual positions, hydro excavation serves as a proactive risk management strategy.

Many municipalities and utility owners now require hydro excavation for verification before HDD operations near critical assets. This further emphasizes its value as a safety and compliance tool.

5 – Enhanced Compliance and Risk Management

Regulatory frameworks such as OSHA’s excavation safety standards and utility protection laws (e.g., the Common Ground Alliance’s best practices) strongly advocate for non-mechanical digging near known utilities. Hydro excavation is aligned with these regulatory preferences. It helps contractors stay in compliance and reduces the likelihood of fines or shutdowns.

Furthermore, hydro excavation enhances documentation and transparency. The process can be logged, photographed, and reported, offering proof that a contractor took every reasonable step to avoid utility strikes. This documentation can be invaluable in the event of a dispute or investigation, further shielding the contractor from liability.

In conclusion, hydro excavation is more than just an efficient method of soil removal — it is a cornerstone of safe, modern HDD practices. By enabling precise, non-destructive digging, it protects workers, infrastructure, and communities from the dangers associated with live utilities and inaccurate mapping. It also reduces the need for manual labor, minimizes site restoration, and dramatically lowers contractor exposure to costly damages and legal risks.

As HDD continues to grow in popularity for urban development, fiber optic installations, and utility upgrades, the integration of hydro excavation is not just a best practice. It’s a critical safety standard that smart contractors can’t afford to overlook.

Tony Bokhoven is director of sales and business development at Ring-O-Matic.

Latest Posts

- Puris, Per Aarsleff Partner to Strengthen Lateral Rehab in Canada

- Vortex Companies Rebrands Grout Line to Maverick Grouts

- Vermeer Unveils VXT400, VXT500 Vacuum Excavators

- How to Reestablish Service Connections After In-Building CIPP Rehab

- How to Handle Dealing with a Railroad on Your Project