Tech Forum – Three Considerations for Locating in High Interference Areas

Cabello

Identifying underground utilities through locating should be the first step on any underground construction project. Typically handled by a locate technician, utility locates are very important to the prevention of utility strikes, equipment damage and jobsite delays.

However, as the underground construction industry continues to grow and underground environments become increasingly more congested, locating technicians are experiencing an influx of pain points. Many are stretched thin with high ticket demands, short turnaround times and a shortage of workers. These difficulties mean that locate technicians are often forced to quickly move from jobsite to jobsite – and if one ticket is more challenging, the technician may not have the time to adequately troubleshoot, verify that their locate is correct and still complete their allotted tickets for the day.

While an individual locate technician may not be able to solve the challenge of high-ticket demand and the labor shortage, understanding the top locating jobsite challenges, and how to solve them, will help locate technicians stay on schedule.

RELATED: PRO Tips & Product Showcase – Utility Locators

Understanding Your Interference

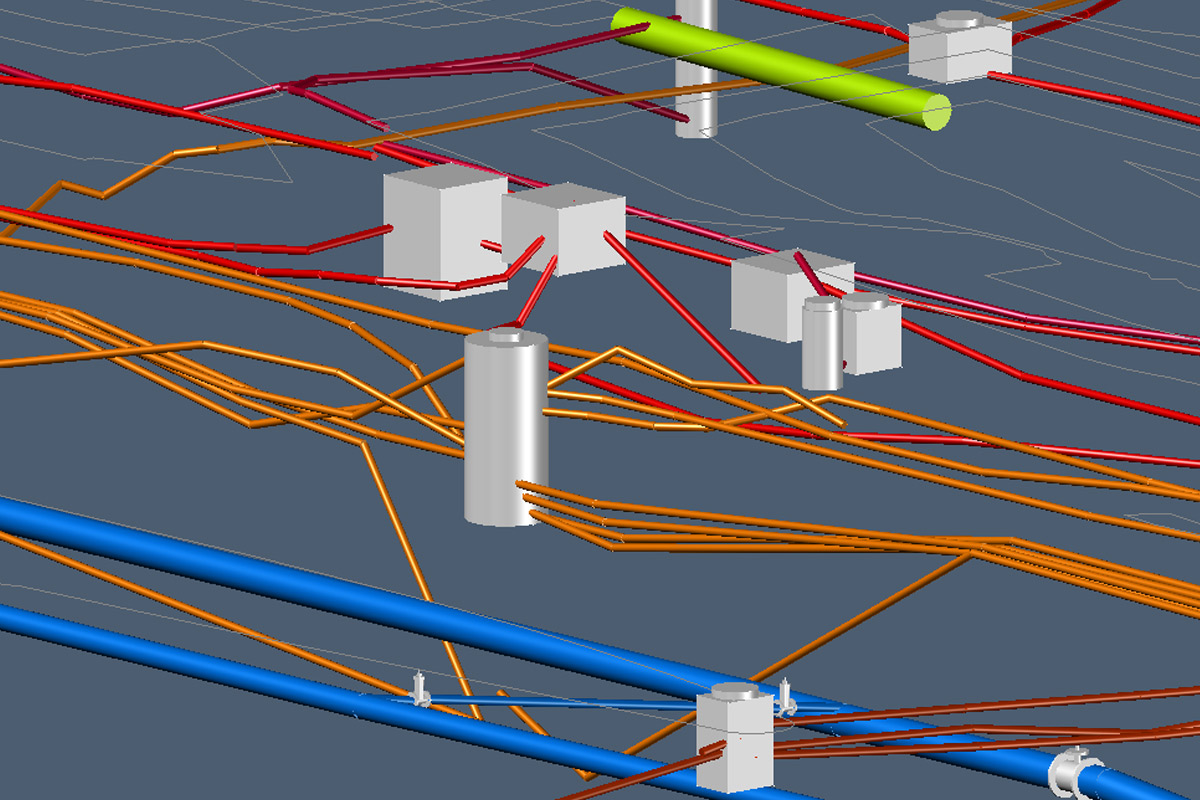

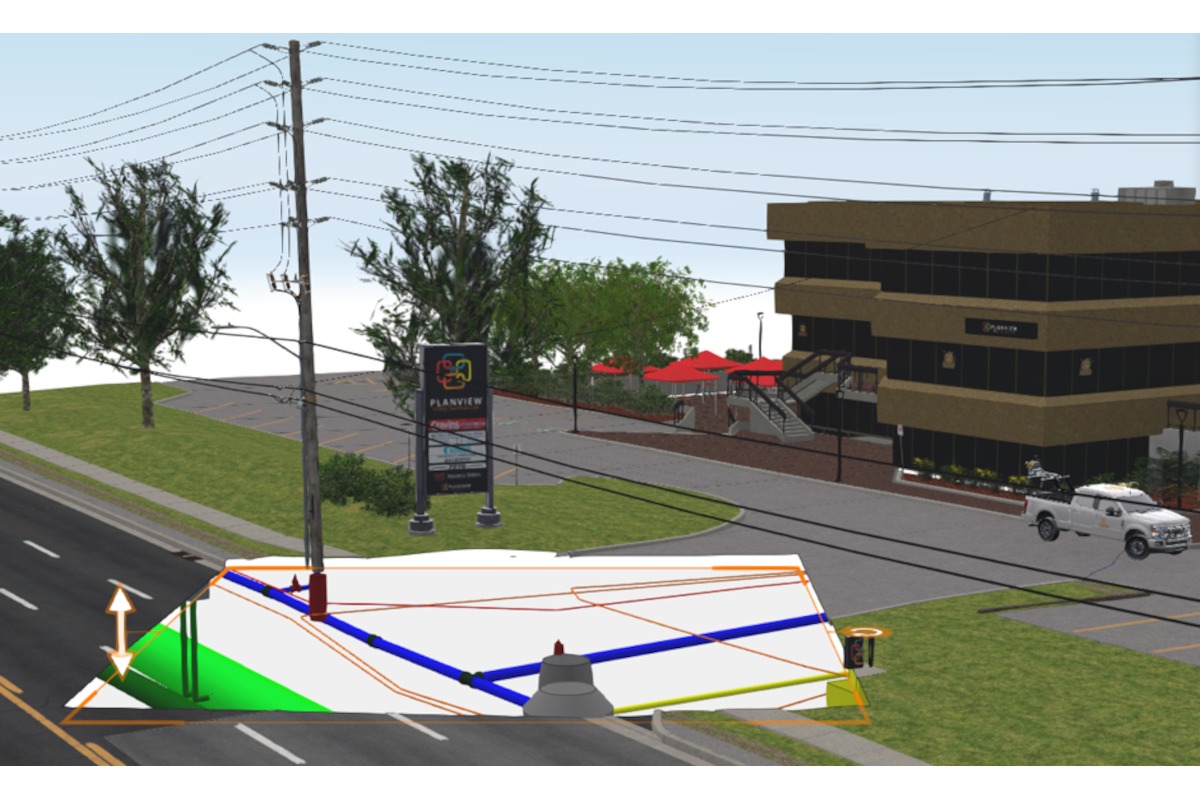

As the underground construction industry grows, locate technicians are seeing jobsites that are more complex, especially in urban areas that are already congested with fiber, gas, electric, water and sewer lines.

These congested areas pose some major pain points. For one, locate technicians can experience interference that could affect the accuracy of the locate. Interference is the most common problem locating technicians face. It can distort the locating signal and provide inaccurate information. To determine possible interference, locate technicians should walk the jobsite path – prior to the start of the locate – and visually observe previous locate markers, culverts, fences and more.

Interference can take an active or passive form. Active interference comes from sources that have their own signal and in turn can distort your target signal. This potentially can cause your signal to bleed off onto an adjacent utility risking a mismark. Common sources of active inference include Cable TV, dog fences, cathodic protected gas mains, electrical-based irrigation systems and so on. Passive interference comes from sources without an electrical signal such as storm culverts, chain link fences or even the rebar used in underground construction.

While not all sources of interference are visible, some manufacturers are designing equipment that will scan the jobsite and inform the locate technician of any potential active interference that is present in the area. One option for locate technicians is AIM (Ambient Interference Measurement). Locate technicians using a locater that has AIM on their receiver can use it to visually see which frequencies have the most or least amount of interference. As a best practice, lower frequencies like 263Hz through 870Hz are the best choice when encountering passive interference.

Find the Correct Frequency

Once a locate technician has identified possible interference, they must then find the frequency of their target utility. As a best practice, locate technicians should start with the lowest possible frequency and work their way to a higher frequency. If locate technicians are using too high of a frequency – between 8.01khz and 44.6khz – they run the risk of the locate signal bleeding off onto an adjacent utility line. This can result in a mismark and potentially lead to a utility strike. However, if they are using too low of a frequency, they run the risk of not picking up a signal at all. When working in highly congested areas, using a locator with multiple frequencies can help locate technicians easily make the adjustments needed to accurately locate the correct utility.

Once they have found their frequency, locate technicians should use a direct connection whenever possible or is safe to do so. Direct connection is the most accurate and preferred method of locating utilities. It’s essential to achieve a proper ground when using a direct connection. To complete the circuit, locate technicians should drive their transmitter’s ground take in the dirt as far as they can. Once the transmitter’s mA’s increase, then the transmitter can apply a stronger signal if necessary. However, if the connection point is surrounded by concrete, soft ground or just out of their reach, then an extended ground cable can be used to help make a connection. When working with soil that is dry and less conductive, locate technicians can pour water on their ground stake to help the current flow.

This is where a transmitter’s power comes in. A transmitter is a locate technician’s workhorse – It has to fight the impedance of the line to more accurately apply the signal to the target utility. Low frequencies may struggle to apply a signal. However, by leveraging the wattage of their transmitter and increasing the power level, they can more efficiently drive those low frequencies further down the line.

On a typical transmitter, 500 ohms or less indicates there is a good signal line with minimal resistance, which can more accurately locate the utility. However, if there are more than 10,000 ohms, a locate technician might want to increase their frequency or increase their power level to cut through the resistance.

RELATED: PRO Tech Tips – Utility Locators

Don’t take Shortcuts

Every jobsite is different and poses its own unique challenges. Going through the proper procedure of isolating a utility might sound like a no-brainer, but when technicians are challenged with time constraints due to high ticket requests, they might try to find shortcuts.

One shortcut that is hindering a technician’s efficiency is sticking to a favorite frequency. Since all frequencies have the potential of bleeding off and creating a mismark, it’s important not to get into the habit of using the same frequency. This often leads to inaccurate results causing the technician to restart or use a different option because they didn’t take the time to properly locate.

More and more utilities are being installed underground and a locate technician’s jobsite can often look like a Jackson Pollack painting after they’re done. And while ticket demand will continue to follow the trajectory of the growing HDD industry, it is important for locate technicians to have a comprehensive understanding of the techniques and best practices. This can help them stay efficient, overcome common jobsite challenges, mitigate damage and ensure a safe and successful operation.

Rodolfo Cabello is the Utility Locating Product Manager for Subsite Electronics.