SUE Methods Used in Florida Hospital Renovation Project

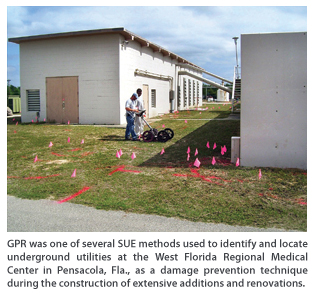

When the Pensacola, Fla.-based West Florida Medical Center embarked on an extensive $100 million renovation project, it wanted to limit its exposure to construction-related underground utility risk. One of the damage prevention measures it used was subsurface utility engineering (SUE).

SUE is a highly efficient, nondestructive engineering process that incorporates civil engineering, surface geophysics, surveying and mapping, nondestructive vacuum excavation and asset management technologies. The process is much more sophisticated than the traditional utility depictions on plans taken from as-built records and utility system drawings. The previous method of relying on information from old plans and records regarding the location of underground utilities may not be sufficient in congested areas. Often, subsurface facilities are not where the records indicate and the size, depth and material composition is an educated guess, at best. Statewide one-call systems normally do not respond for privately owned utilities, like those found on a hospital campuses.

The work at the 36-year-old West Florida Medical Center has been under way since 2000 and includes a new emergency room, a $20 million operating room addition, a newly renovated radiology department, a new entrance and reception lobby, as well as major repairs from Hurricane Ivan damage in 2004. The primary entry point of West Florida Hospital’s service to the community is its network of neighborhood primary care physicians, along with specialists, nurses and staff at the Emergency Department of West Florida Hospital. West Florida Hospital’s front line is backed by a 500-bed acute care hospital and an extensive range of treatment centers and institutes, including a Rehabilitation Institute that serves as the region’s only comprehensive medical rehabilitation facility and a full-service adult and geriatric psychiatric hospital.

Subsurface Utility Engineering

More public and private entities are beginning to use SUE to limit their risks associated with underground utilities. SUE identifies and classifies quality levels of existing subsurface utility data, as well as maps the locations of underground utilities. The data allows for developing strategies and making informed design decisions to manage risks and avoid utility conflicts and construction delays. If a utility conflict does exist, viable alternatives can be found during design to resolve the conflicts before any damage is done or costs incurred during construction.

In 2003, the American Society of Civil Engineers (ASCE) published (updated in 2008) a document titled Standard Guideline for the Collection and Depiction of Existing Subsurface Utility Data. This standard formally defined SUE and set forth standard guidance for collecting and depicting SUE information. The standard establishes four quality levels of information about existing underground utilities, levels D through A.

Records research is the center of Quality Level D and includes field reviews, interviewing key utility personnel, reviewing government permitting agencies and conducting a web-based search for any unknown utilities that may have been recently permitted and installed.

Quality Level C involves field observation and survey of visible above-ground utility facilities, such as manholes, valve boxes, telephone pedestals and other surface features and correlating this information with existing Quality Level D utility records.

Subsurface utility designating encompasses Quality Level B information. Designating is the process of using a surface geophysical method (or methods) to interpret the presence of a subsurface utility and mark its horizontal position, also known as its designation, on the ground surface. Surface geophysical methods include those designed to use and interpret ambient or applied energy fields to identify properties of, and structures within, the earth. Such methods typically include variants of electromagnetic and magnetic imaging of underground utilities and marking the location on the surface of the ground.

Quality Level A involves the exposure and recording of the precise vertical and horizontal location of an underground utility. This typically involves nondestructive digging equipment, such as vacuum excavation, at critical points along an underground utility’s path to determine the precise horizontal and vertical position, size and material composition of the underground utility line. By locating and surveying the utility’s precise horizontal and vertical position, project design participants can plan for proper protection, eliminate potential damage and safety hazards during construction and avoid unnecessary and costly utility relocations.

Data Collection and Asset Management is a process of surveying the Quality Level B designating and Quality Level A locating utility data and entering it into a computer-aided design (CAD) system, geographical information system (GIS) or other data representation system.

Finally, a Conflict Analysis is completed using engineering judgment, based on engineering and design best practices, to evaluate and compare depicted utility designating and locating information with proposed plans to inform all stakeholders of potential conflicts, potential resolutions and costs to rectify the problem.

West Florida Regional Medical Center

Early in the design of the $20 million operating room addition, underground utilities were identified as a major concern. Hospital facility staff and Hoar Construction’s project superintendent Mike Broadaway believed the proposed two-acre site had more than 40 underground utilities, including medical gases like oxygen and nitrogen, security and HVAC controls, emergency power, fuel oil, natural gas, buried electric, water, sanitary sewer, telephone, data, storm drainage, cable TV and chill water and hot water supply and returns.

As a result of the SUE investigation, some underground utilities were relocated, some were retired or abandoned and some utilities were protected with the design being updated to work around the existing utilities.

“A $20 million operating room was constructed in a congested underground utility area without a single utility break or delay,” Broadaway said. “This was a major accomplishment considering that no utility record drawings were available.”

Intensive studies conducted in the United States and Canada have proven the significant cost-savings of subsurface utility engineering when applied during the design of all types of new, rehabilitated and expanded facilities. Typical construction cost-savings have been calculated to be $5 for every dollar invested in subsurface utility engineering during design, and these savings do not include the benefits of avoiding unplanned utility outages.

James Allen is a senior project manager with Cardno TBE, Lake City, Fla.