SUE and Underground Infrastructure Project Planning

Knowing What’s Below Key to Avoiding Delays, Catastrophes on Underground Infrastructure Projects

In the underground infrastructure construction world, a good proverb to adhere to is, “An ounce of prevention is worth a pound of cure.” In this world, that ounce of prevention comes in the form of subsurface utility engineering (SUE), a branch of civil engineering practice dedicated to managing the risks of underground utilities.

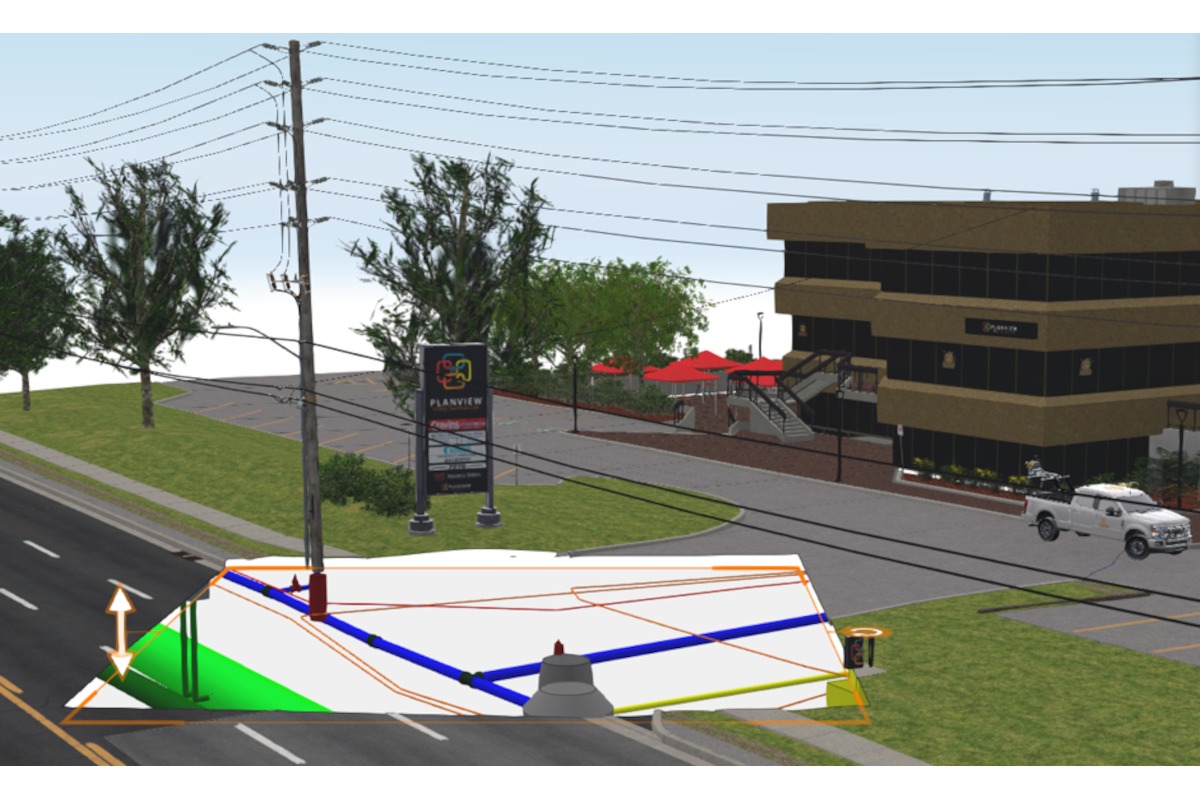

SUE goes beyond designating and locating utilities and includes the review of utility data and managing the data in the form of maps and other digital models. It is a key component in the design phase of projects.

While some form of SUE has been a component on construction projects for decades, the formalized practice of SUE didn’t start gaining traction until 2002. That’s when the American Society of Civil Engineers (ASCE) released ASCE 38-02 Standard Guidelines for the Collection and Depiction of Existing Subsurface Utility Data.

As stated in the original abstract, “Standard Guideline for the Collection and Depiction of Existing Subsurface Utility Data presents a credible system for classifying the quality of utility location information that is placed in design plans…Whether used as a reference or as part of a specification, the standard will assist engineers, project and utility owners, and constructors in developing strategies to reduce risk by improving the reliability of information on existing subsurface utilities in a defined manner.”

With the explosive growth of the industry since the release of ASCE 38-02, it’s been updated and renamed in 2022 as ASCE 38-22 Standard Guideline for Investigating and Documenting Existing Utilities. The update also bred a companion standard, ASCE 75-22 Standard Guideline for Recording and Exchanging Utility Infrastructure Data; the former focuses on the utilities already underground and the latter establishes criteria for the new utilities going in the ground.

The Road to SUE

James Anspach, P.G. (ret.), Dist.M.ASCE, who chaired both the writing of ASCE 38-02 and its recent update, is one of the people who has stood at the forefront of the SUE industry, and is often heralded as the father of the industry. While Anspach doesn’t shy away from this title, he is fast to point out that he was not alone in this endeavor.

Anspach’s journey and the roots of SUE can be traced to 1978 and his work at Heath Consultants. That’s where the recent Penn State grad – with a degree in geology, geophysics and geochemistry – got his start. Heath Consultants specializes in pipeline leak detection and corrosion management and hired Anspach as a traveling consultant.

“If you want to find a leak in a pipe, you have to first know where that pipe is. In those days, knowing where the pipe is, was called witching because it was witchcraft,” Anspach recalls. “I was the only geologist on staff, and I was able to say that it’s not witchcraft. It is an inexact science, but it’s actually an application of near surface geophysics tools to sense the presence of a pipe or linear structure in the ground.”

From Heath, he went to work for Garon Stutzman, at So-Deep Inc., which was geophysical methods and air vacuum systems to measure and locate exactly where utilities were located. Anspach, intrigued by this new endeavor and new use of technologies, joined So Deep where he looked after the company’s work locating underground utilities using geophysical methods. It was during his time at So-Deep, that Anspach and his colleagues honed what would become SUE and ASCE 38-02.

Anspach recalls that in 1990 he could count on his hands the number of firms doing this work, in the early 2000s that number blossomed to about 100, thanks in part to an effort by Paul Scott the Federal Highway Administration (FHWA) and, as a result, departments of transportation adopting a SUE approach to projects in their rights of way. By 2010, Anspach checked and stopped counting at about 500.

“The real touch points of the development of the profession were developing that concept of designating, locating and data management and then adding in the utility coordination,” Anspach says. “Beyond that, it was the development of ASCE 38-02 and then the development of the Utility Engineering & Surveying Institute (UESI) at ASCE. These are the lynch pins of getting utility engineering accepted as a valid field of civil engineering. There were little steps along the way that helped, but these were the big ones.”

Establishing a New Engineering Practice

With the establishment of UESI in 2015, utility engineering became a recognized branch of civil engineering that focused on the cradle-to-the-grave lifecycle of underground infrastructure systems. Utility engineering, according to UESI, includes the planning, position, design, construction, operation, maintenance and asset management of any and all utility systems, as well as the interaction between utility infrastructure and other civil infrastructure.

“I can’t put a number on it, but the industry has grown substantially in the last decade. It has become a well-defined industry and a service many engineering firms now provide,” says Impulse Radar USA Inc. president Matthew Wolf. “We sell GPR equipment to that industry and it’s been a big part of our growth in the last 10 years.”

One of those department of transportation employees who was an early adopter of SUE practices is John Campbell, P.E., M.ASCE. He currently works as the Texas branch manager for T2 Utility Engineers (T2ue), arguably the largest SUE provider in North America, but before that, Campbell spent 27 years with the Texas Department of Transportation (TxDOT) as a utility engineer, director of its right of way (ROW) engineering department and then as director of the TxDOT Right of Way Division.

“My responsibilities [as director of ROW engineering] at that time were for the existing utilities on TxDOT’s 1.2 million acres of right of way property. I immediately had this concern, coming from my management background, that if I am responsible for these existing assets, I’ve got to have some mechanism to inventory them and know where they are,” says Campbell. “That really started a personal pursuit to figure out how we could better identify where existing utilities are.”

While Campbell was interested in this from a DOT standpoint, Lawrence Arcand, P.Eng., M.ASCE, was tasked with helping the industry grow in Canada. In 2003, Arcand joined the new joint venture of U.S.-based Tampa Bay Engineering and Canada-based Totten Sims Hubicki to help drum up SUE work in Canada. Known as TSH/TBE JV, it completed the first SUE project in Canada in 2002. The company would eventually grow to become T2 Utility Engineers.

“It was brand new. There was a lot of, ‘Oh, we don’t need to do that. We don’t need SUE. We do it this way.’ It was many, many years of hearing the reasons why they didn’t need SUE,” recalls Arcand, who worked at the JV and T2ue into 2020. He left the company and started 4Sight Utility Engineers in Ontario.

“It’s grown by leaps and bounds here in Canada. It went from 20 years ago not a single soul had even heard of it, to now in Ontario it’s commonplace to list SUE and the ASCE 38 standard in all major civil RFPs,” he says. “It’s becoming more common in other parts of Canada, particularly Alberta and [British Columbia]. There are now way more people who provide the service. It’s a bigger pond with more fish.”

SUE and Trenchless Technologies

As an industry, SUE has its use on any project – public or private – that breaks the ground from residential developments to new building construction and major road work to the installation of underground utilities using open cut and trenchless. It’s the latter where the benefits of SUE shine.

All on the panel agree that it is of the utmost importance to know – to the best of your ability – what is beneath the surface especially when using trenchless installation methods that can go thousands of feet before seeing the light of day.

“On trenchless, SUE becomes extra important because there is no opportunity to identify anything else,” says Arcand. “With shallow trenchless HDD, microtunneling and the like, you’re boring right beside existing water, sewer and electrical. If you don’t know where that is, that becomes a pretty scary endeavor.”

So the question becomes: At what point does an owner or contractor decide that a SUE approach is needed on their trenchless project?

According to Wolf, it comes down to what level of risk the owner and/or contractor are willing to assume. It’s not a damage prevention tool, so much as it is a smart design tool, Wolf notes.

“I would argue that a SUE approach should be used on every project. The decision must be based on the information that you have,” he says. Adding that maybe in a rural setting — where utility congestion is at a minimum — a Quality Level D approach will be sufficient. “The records might indicate there is one facility in that corridor. So, you might take a Quality Level B approach there to verify using GPR or electromagnetic (EM) systems. But do you need a stamped engineers drawing for that? Probably not.”

It’s the assignment of the Quality Levels D to A to each segment of the underground utilities, and the stamped record by a certified engineer that are the hallmarks of the practice.

“It’s the product that makes SUE different from a Call 811 product. The product you get from 811 is the response, and maybe their deliverable is paint on the ground, so you now have some indication on the ground of some utility location that is within a wide area,” says Campbell. “Our deliverable, when you perform a comprehensive utility investigation, is the attempt to depict, document and preserve that information for later use by your client. Our product will be signed and sealed by a professional to effectively transfer that risk of the unknown of the subsurface over to the investigator. We’re a professionally licensed engineering company, so we can put an engineer’s seal on the deliverable, and the deliverable is in accordance with the ASCE 38 standard.”

Arcand adds, “In my mind, SUE is one level of protection. If a contractor is going out to build something and they don’t have accurate drawing that shows where the underground utilities are, they’ve already failed.”

He notes that the role of a locator called out on a One Call ticket should be the last level of protection as opposed to the first and only level of protection on a project. “It should be that you have an accurate drawing of what’s there. That way, the designers can design the projects safely. Either not as close to existing infrastructure or with the necessary protection schemes in place if it is close. Then the role of the locator is to mark those points out,” he says.

ASCE 75 – The Road Ahead

With an established standard in place, it is ASCE 75 that foreshadows what is to come for the field of SUE as it is quite literally the roadmap to mapping and document the new infrastructure going in.

“The industry will always struggle until we get better utility as-built record information. There never existed any standard, in the United States, by which to record as-built information,” says Campbell. “That’s what ASCE 75 sets out to do. It was written with the understanding and expectation that the evolution in technology is such that we need to be thinking in terms of how the information we collect will contribute to a future world of 3D design and modeling of utility infrastructure.”

The standard, which draws from and expands on the Canadian CSAS250 standard, specifies essential elements for documenting the location, geometry and feature attributes of underground and aboveground utility infrastructure, with a particular focus on enabling creation of 3D digital twins for newly installed and/or exposed utility infrastructure.

“ASCE 75 is really what points us towards the future as the essential element that will contribute the most. Because ASCE 75 offers that structure of the minimal attributes that need to be captured at installation. Here are the suggested processes and procedures for doing that capture. And here is the structure that the data should be in so that it can be transferable,” says Campbell. “That to me is the most important part of it. ASCE 75 is looking to inform future investigations by incorporating that precision in the vertical dimension and gathering the data at installation.”

Arcand and Campbell both joked that if every project used SUE, eventually there would be no need for people in the SUE field. Though they – along with Anspach and Wolf – realize that there is much work to be done going forward.

“There are still people who don’t get it and can’t accept that when you run this process that there is a financial windfall downstream, but you must pay upfront to get it,” says Wolf. “The decision-makers who don’t have the foresight and don’t understand that an upfront cost can save a lot of dollars downstream – that’s the only thing slowing growth. The data is in, it makes zero sense not to use a SUE process to head-off problems.”

That’s where the panel agrees that associations and sanctioning bodies play a critical role, as a place where all stakeholders in the process can gather in a common discussion area to get this education. A few of the organizations helping educate and inform are UESI and FHWA, the American Association of State Highway and Transportation Officials (AASHTO), Buried Asset Management Institute-International (BAMI-I), Common Ground Alliance (CGA), National Utility Contractors Association (NUCA), the North America Society for Trenchless Technology (NASTT) and the Subsurface Utility Engineering (SUE) Association. Just as important are university-based activities like those taking place at Iowa State University, where Anspach is now teaching a graduate class, developing further classes, and conducting further research and outreach.

“I think the future is in getting our younger neophyte engineers and constructors to understand the issues of utilities and give them a toolbox to work through those issues,” says Anspach. “That toolbox will be a big toolbox. It’s not just going to be contract locating for damage prevention and SUE for planning and design. It’s going to be a host of technologies that are digital, in the cloud and instant.”

With an established and updated standard, a new standard and a recognized field of practice via UESI, SUE is poised for continued growth and acceptance across North America and – in some form – across the globe.

“The common problem that we have is there are a whole bunch of utilities in the ground that are in the way of a whole bunch of new infrastructure projects, and they can create health, welfare and safety issues to the public,” says Anspach. “It’s not rocket science what we’re doing. It’s common sense.”

Mike Kezdi is the managing editor of Trenchless Technology.