Static Pipe Bursting Record Set in New Mexico

According to Vis-Com president Ron Lucero, the Taos project provided thecompany with a good opportunity. He said, “Before this particular project, wehad pneumatic pipe bursting experience for replacing sewer mains, but had neverdone a water main bursting project before. We partnered with TT Technologies forequipment training to accomplish the project.”

In order to replace the nearly 16,500 ft of 8-in. PVC, Lucero used aGrundoburst 800G static pipe bursting system from TT Technologies, Aurora, Ill.In addition to the relatively large scale of the replacement, the project alsoincluded one single run of more than 2,800 ft, setting what is believed to be anew world record for the longest continuous static pipe bursting run.

Contractor Background

When it comes toutility contractors, Vis-Com is as diverse as they come. With an average crewsize of 75 employees, the company takes on a wide range of projects. Lucerosaid, “We’re basically a general contractor that specializes in utilities — allutilities. We do signalization, highway lighting, directional drilling and waterand sewer pipe bursting. We are a natural gas distribution maintenancecontractor as well. We also perform power line construction underground. Sobasically anything that has to do with utilities, we’re in it.”

Lucero has more than 30 years of utility contracting experience behind himand started Vis-Com in 1994. He is always looking for ways to improve safety andefficiency. Trenchless pipe bursting has been one of the methods that haveallowed him to do both. The project in Taos also gave Lucero and his crews theopportunity to expand their bursting knowledge.

Static Pipe Bursting

The use of staticpipe bursting for water main replacement is growing in North America. Accordingto TT Technologies pipe bursting specialist Tad Oldenburg, static pipe burstingis gaining popularity with contractors because of its capabilities. Withhydraulically powered static pipe bursting systems, contractors have the abilityto not only burst and replace fracturable pipes but also ductile iron, steel andlined pipes, as well as pipes with ductile iron and steel repairs.

The static bursting process is basically a three-step process. Afterestablishing launch/insertion and exit machine pits, bursting rods are insertedthrough the existing line from the exit pit to the launch pit. At the launchpit, the bladed rollers, bursting head, expander and new HDPE is connected tothe bursting rods. Finally, the entire configuration is pulled back through anexisting line by a hydraulically powered bursting unit. As the bladed rollersare pulled through, they split the host pipe. An expander attached to therollers forces the fragmented pipe into the surrounding soil whilesimultaneously pulling in the new pipe.

Oldenburg cites the bursting rods as a key component to static burstingsuccess. He said, “Patented Quicklock bursting rods are linked together, notscrewed together like traditional drill stems or other static systems. Thissystem speeds the installation process, as well as the breakdown procedure. Therods can be quickly removed one at a time at the exit pit as bursting is inoperation. And while HDPE is commonly used, new techniques and technologies areallowing contractors a choice when it comes to product pipe. Other pipematerials that can be installed through static bursting include ductile iron,PVC, specially designed clay and even steel.”

On the Job

According to Vis-Com projectmanager Mark Fogell, the existing trunk main for the Taos project wasfiberglass-wrapped, 8-in. PVC. The troublesome pipe had a history of failing andneeded to be replaced, but with a large portion of the main running underasphalt roads, driveways and lawns, the project was specified as pipe burstingonly. Fogell said, “The goal of the project was to keep disruption down to aminimum and we were able to do that with the static bursting set up. A goodportion of the project ran under a major county road. Limiting asphaltrestoration was key to keep project costs in line and reducing inconvenience tomotorists.”

Vis-Com superintendent Roy Maxey said his crew had little problem masteringthe static bursting system. “The crews took to the static bursting processrather quickly,” he said. “It’s a very nice setup. It’s easy to operate, it’seasy to handle and it works very well.”

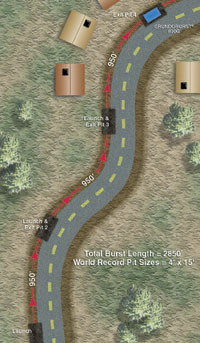

One particular stretch of pipe replacement under a roadway resulted in aworld record pipe bursting run. Oldenburg explained, “The big run measured 2,850ft. The previous bursting record was a pneumatic project that went just shy of2,300 ft. Vis-Com never intended on setting a record. They were just trying tobe as efficient with the project as possible.

“Plus the only way this particular run could be completed with so many turnsand bends was with a static system and Quicklock rods. Bursting around thesebends and curves can pose challenges for many static bursting systems. Theimportance of the bursting rods cannot be overlooked. Quicklock style burstingrods actually form a flexible chain that, when linked together, has a ratherforgiving bend radius. This accommodates some offset pipe bends.”

Vis-Com crews started by excavating launch and exit pits at regular intervalsthroughout the run. “We set up 4-ft by 15-ft pits in 950-ft increments to allowus to move the Grundoburst after a pull was complete,” Maxey said. “We wouldpull in a 950-ft segment, move the machine, add more pipe and continue pulling.It really worked out well. We were able to install a single 2,850-ft run over athree-day period. Everyone was very impressed by the results.”

Oldenburg said, “The Vis-Com crews were excellent. They were able to get ahandle on the bursting process quickly and then complete a world record lengthburst. I think that speaks volumes about Vis-Com.”