Saving Money: Piercing Tool Care without Going in the Hole

July 31, 2015

Equipment maintenance plans for serviceable earth-piercing tools fall into two categories: letting someone else do it, or doing it in-house. When a contractor has only a few tools to maintain that are not in constant use, the expense and delay of sending them out for service might be acceptable bumps in the cost of ownership. Contractors building up a tool fleet see those costs rapidly multiply.Shannon Mulkey needed to reduce both the cost and the downtime for repair and maintenance of his expanding earth-piercing tool inventory. Mulkey is the warehouse and service manager of Southeast Connections LLC (SEC), working from its main Conyers, Ga., location. SEC is a pipeline, facilities and HDD/boring construction contractor providing services to the natural gas industry from its eight offices in Georgia, Tennessee, Alabama and Virginia.

At the time, Mulkey said, SEC had only about a dozen piercing tools. Today, 120 of the contractor’s 867 employees are using 60 HammerHead Moles for utility installations on a daily basis.

In-house Servicing

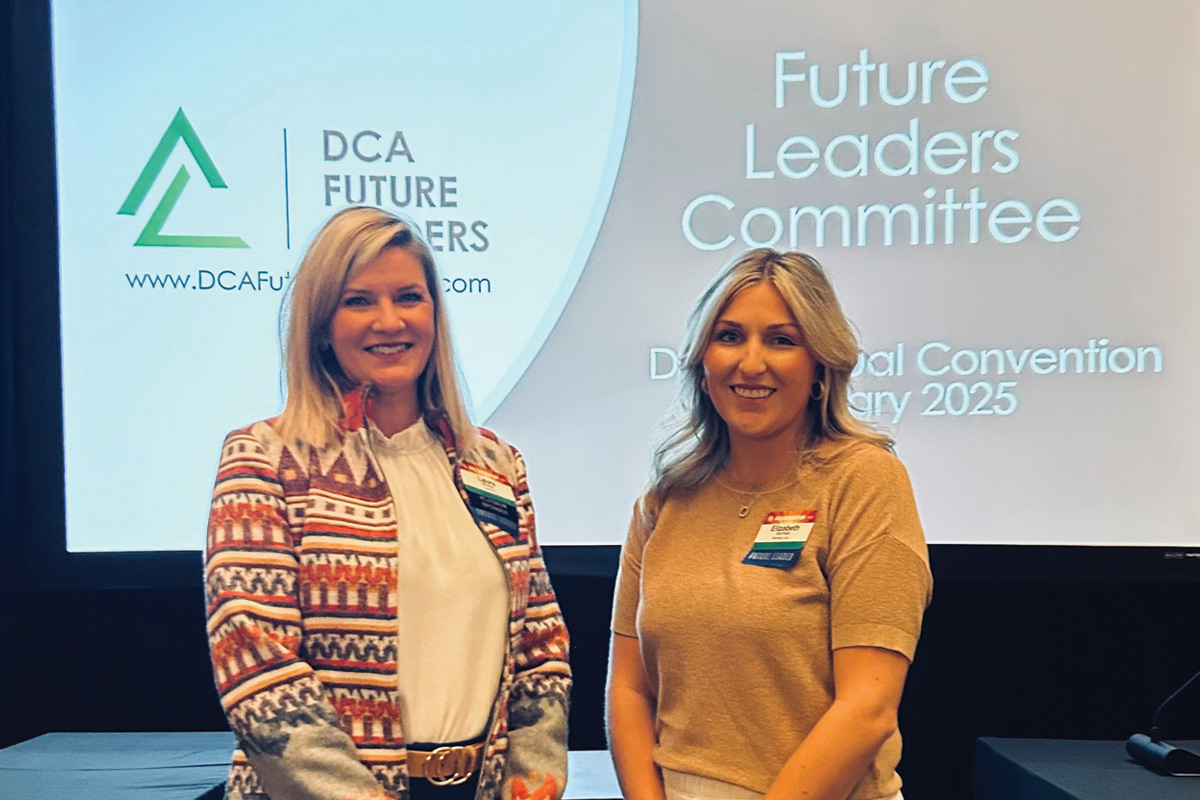

Instruction at an Southeast Connections training seminar by HammerHead Trenchless Equipment’s Chris Alexander included instruction on all parts of Mole maintenance, including detailed, hands-on instruction for servicing the rear anvil assembly.

Mulkey had hoped performing in-house servicing and making repairs immediately on the earth tools that SEC previously owned would not only save on service costs but promote routine maintenance to extend tool life, maintain peak performance, and increase overall utilization and productivity.

Unsatisfied with his own attempts to rebuild the tools, he sought training through his dealer, Ditch Witch of Forest Park, Ga. Although Ditch Witch is the authorized distributor of HammerHead Trenchless Equipment’s product lines, its technicians are OEM-certified to work on other earth-piercing tool brands for their customers, as well. Through the expertise provided by Ditch Witch’s service department, Mulkey learned right away that it was going to require more than he bargained for. “I didn’t realize how complicated our tools were,” Mulkey said, “or that SEC would need to invest in a special high-power wrench with at least 1,400 psi to open the tool. We didn’t have anything in our shop that could do that.”

Even with the required equipment it would take up to two hours to take down and reassemble the tool. So when Mulkey saw a Ditch Witch technician at the other side of the workshop working on a different brand, he wasn’t certain they were doing the same thing to them. “He had it apart, cleaned and together again in about 20 minutes.” That was Mulkey’s introduction to the HammerHead Mole. “I made up my mind on the spot – I wanted what that guy had.”

Eeny, Meeny, Miny, Moe

Piercing tools available in the market today are designed under one of three distinct design strategies. One, a brand can be disposable, meant to run until it loses so much performance it must be discarded and replaced.

Two, they can be repaired and rebuilt with special equipment, like SEC’s former piercing tools. The owner generally sends the tools out for service and repair.

In contrast, the HammerHead Mole was designed in the late 1980s by two Harley Davidson motorcycle engineers, Steve Wentworth and Rob Crane. Their goal was to make an earth-piercing tool an operator could fix in the field if needed.

The Mole was exactly what Mulkey needed to keep his tool fleet’s cost of ownership down while SEC’s tool fleet grew to keep pace with the burgeoning demand for its earth piercing services.

Brand Conversion

SEC completed its swap-out to the Mole three years ago. During the first year, SEC’s own technicians were performing all maintenance on the tool except for piercing heads. SEC generally uses HammerHead’s active heads on its 2- to 3-in. Moles in the Atlanta area’s clayish soil conditions, relying more on static heads elsewhere. But to achieve his ultimate goal of 100 percent in-house service capability for the earth piercing tools, Mulkey needed to consult with Goodman again, who in turn contacted HammerHead’s southeastern U.S. sales manager Chris Alexander.

In-house service and repair capability of its HammerHead Moles drives up utilization rates and saves Southeast Connections 35 percent in maintenance costs.

Alexander worked with the two over the course of several meetings to create a hands-on Mole training seminar at SEC’s site in Conyers. “In just two days of training,” Mulkey said, “we serviced all of our Moles, completely breaking them down, cleaning them, replacing whatever might need replacing, and putting them back together. Everyone got hands-on training. Chris saw to it they all mastered it, even when it meant taking apart one we’d already rebuilt just so everyone got the experience of taking it apart and putting it back together again.”

Mulkey said Alexander’s expertise and teaching style impressed him: “He really knows this field. A lot of the initial education was covering basic parts and matching manufacturer specifications to the product. Each size has its own torque spec. But then it was all hands on. They guys liked working with him.”

Alexander also taught trainees to distinguish types of damage and to look for their most likely cause, such as improper oiling and dirt contamination. There were also topics Mulkey would not have expected.

“For instance, Chris took time to educate my guys on our compressors and the relationship of volume to pressure,” Mulkey said. “These tools are designed to run on 110 psi. Most of the compressors used for this industry are rated anywhere from 120 to 160 psi. But you can’t count on that. It’s more about volume. You have to make sure the compressor has enough volume to maintain that pressure. A small-volume compressor might say that it’s rated 110 but only be giving you 70 while you’re in the middle of your run. You don’t want the tool to stop working halfway through the run.”

On the other hand, running a piercing tool at excessive pressures can lead to even more serious problems. “Guys think it will make the tool more productive to run higher than 110 psi. Of course, it can – for a bit – but it’s damaging the tool. When Chris was explaining this, right away I was thinking of missiles I’d seen come in before with broken or deformed bodies, flanges, tail pieces. I knew immediately what he meant.”

Mulkey said to him crew safety was far more important than maintenance cost. “Some of the stuff happening to tools running that hard is dangerous and could hurt someone. They’re down in the pit next to them.”

Following Alexander’s recommendations, all of SEC’s compressors now have regulators to maintain correct psi, protecting both tools and equipment from excessive pressures.

Mulkey has been tracking maintenance costs, which has proven the merits of his plan: “I have nothing but good news. We’re saving 35 percent a year on overall maintenance. Also figure in that the tool itself costs less than the brand we were buying, that the tools are turned around and go back to work the next shift, and it’s a no-brainer. This was the way to go.”

Subsequent training is also provided in-house, Mulkey said: “I applied what Chris taught to make our own training courses. He taught us well enough that now we can teach others.”

Mulkey said in the three years he has worked with HammerHead Moles, he has not yet seen one wear out yet. “But even when that day comes, since every part of the Mole is replaceable, we’ll just keep rebuilding them until we decide we ‘want’ a new one.”

Joe Bradfield is senior writer for Ellenbecker Communications, an international communications firm specializing in the drilling, mining, and construction.