New Software Offers Unified Reporting to CCTV Manufacturers

March 20, 2015

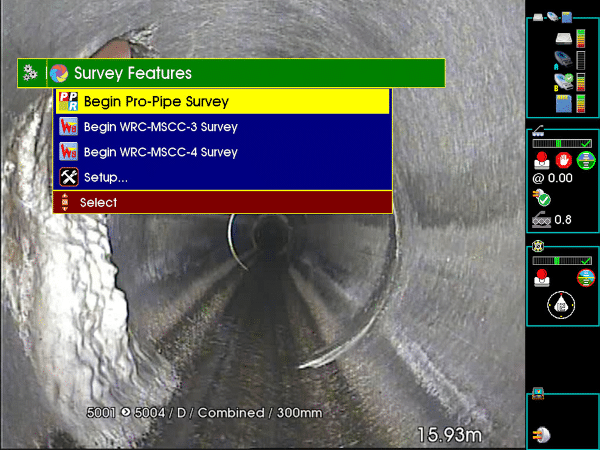

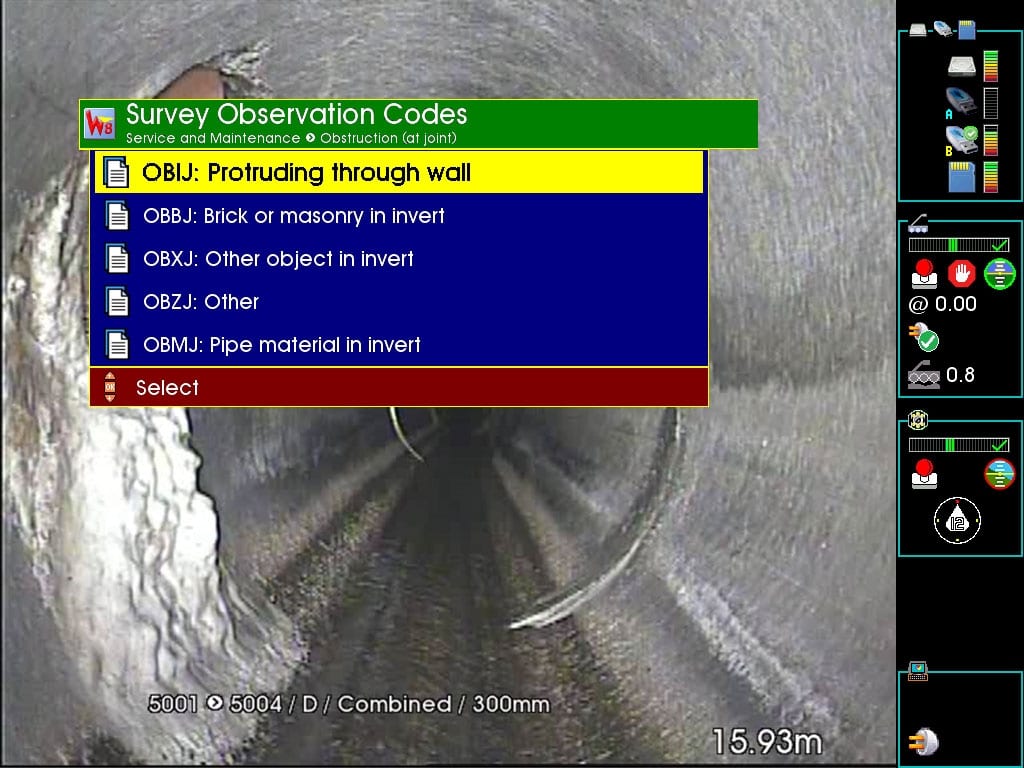

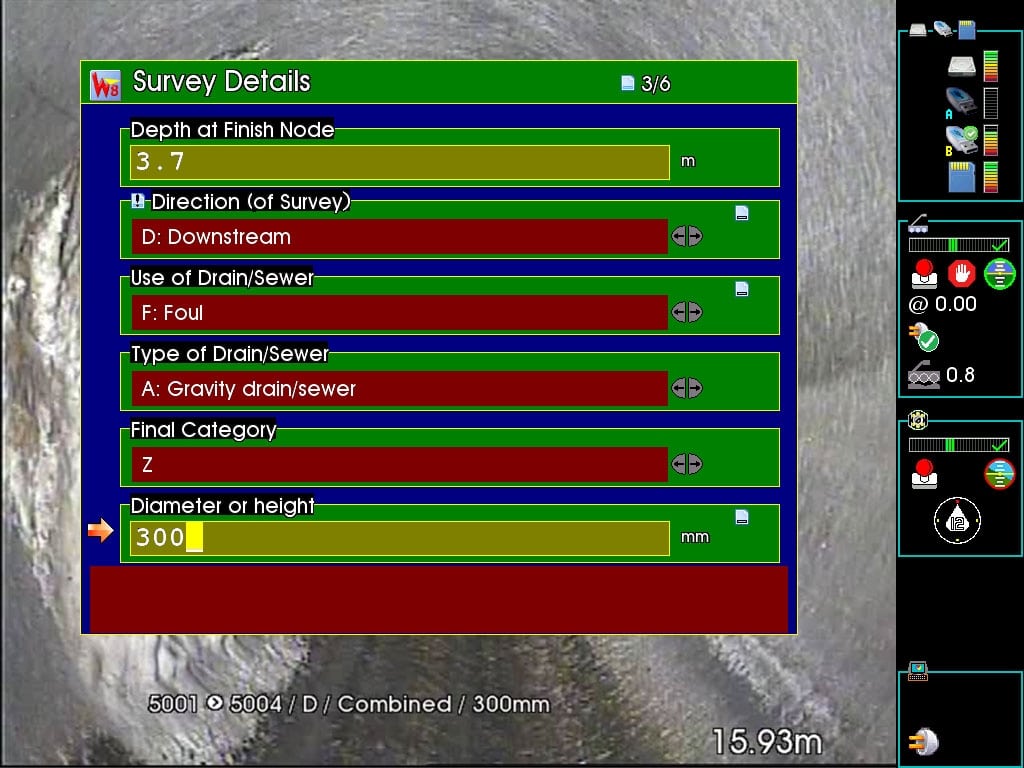

- Screen shots from various functions within the Mini-Cam survey software showing start screen, survey and coding details.

Increasingly across the pipeline inspection market, clients are looking to obtain standardized survey reports that can easily be compared from one survey to the next to highlight changes and deterioration in their pipe networks. This is particularly true of the U.K. water sector, but also in many other countries across the globe, where WinCan reporting software is fast becoming the industry standard.

Increasingly across the pipeline inspection market, clients are looking to obtain standardized survey reports that can easily be compared from one survey to the next to highlight changes and deterioration in their pipe networks. This is particularly true of the U.K. water sector, but also in many other countries across the globe, where WinCan reporting software is fast becoming the industry standard.In the past, this has often meant that surveys have been undertaken that then have the handled a second time to match the in-field survey report with the standard defect catalogues, developed by WRc, and utilized by WinCan to create these final client reports.

Now, however, this need be no longer the case. With the explosion in portable devices such as Smart Phones, Phablets and Tablets and the huge expansion of these types of technologies used as part of the control systems and data recording package now being offered by CCTV inspection systems manufacturers, WinCan has developed a new software package known as WinCan Embedded that will run ‘behind the scene’ during a pipeline survey to make the report creation much quicker and simpler for the operator.

Some innovative manufacturers, including iPek, Mini-Cam and Scanprobe, have now designed and launched WinCan Embedded controllers where certain parts of WinCan software can be licensed to allow the capture of more than just traditional video and pictures using just the CCTV system control unit.

Traditionally, the camera control unit simply captured video and still pictures that could be transferred to WinCan for coding back in the office. In effect, this means that the operators completing the survey twice, once to capture the survey video and once to report and analyze it.

Yet in the modern world where ‘Time is money,’ the WinCan Embedded option can cut out the double handling while also working perfectly as if it were a full blown WinCan connected to the system installed on a PC.

With a fully licensed version of WinCan Embedded, true WinCan raw data can be captured in real time at the time of survey. This is later imported to a desktop WinCan or uploaded to WinCan WEB for creation and delivery of a finalized report directly from site. For data collection, no other license or hardware is required; everything is included within the system control unit.

Where the system has advantages for the CCTV manufacturer is that WinCan is not involved in the design or manufacture of the survey hardware only components of the software portion for reporting. This means that, for the manufacturer, the survey system will ultimately remain as individual to the end-users as it normally would. The system manufacturer will design its ‘front-end’ look and feel to the specifications of its usual design and retain the familiarity that regular users know and like. This also means that the operation of the WinCan Embedded software will differ from system to system but ultimately and perhaps most importantly, the data produced by whichever survey system is used will be fully WinCan compatible.

Why WinCan Embedded?

Talking to the three major CCTV manufacturers currently using WinCan Embedded in their systems, each has both common ground and an individual take on where the software will advance their product ranges.

For instance, for iPek International GmbH U.K. sales and business development manager Paul White said: “We are using WinCan Embedded across the board of our products. We have two control panels for both push rod and crawler system. Our VC200 portable controller system has the WinCan Embedded software in it and can drive both types of camera. This offers the user one control unit for both types of system and can be a major benefit through lower initial cost outlay, as well as providing a system that the user knows on either system.

“The advantage to having WinCan Embedded for the user is that they do not necessarily have to have a full WinCan set up. But provided they have access available they can produce a WinCan report. The data needed for the full report is collected and created onsite by the operator using the standard defect and reporting catalogues. This data is then later downloaded to WinCan to make the full report, without a huge extra workload, which can be edited if necessary. It also means that a full WinCan setup is not needed on every survey vehicle. The front-end of the units also still looks like iPek. Finally, the systems can be upgraded from standard to use the WinCan Embedded system so contractors can then look at applying for work they were previously unable to tender for because they lacked the right reporting capability.”

Mini-Cam Ltd. managing director Nigel Wilson said: “We use WinCan Embedded on all our push rod and crawler cameras. The Push Rods are the SoloPro and SoloPro 360 and the crawler is the Proteus system. Why? Simply because it offers a level of portability that is not possible without it — where the survey system needs either an industrial PC or a Toughbook on board and installed separately. Ours is a self-made system with our own processor and custom-designed software. WinCan Embedded then works within this so that the operator fills in information within the Mini-Cam system using the standard references and defect catalogues, completing the report directly within the Mini-Cam system instead of having to double-handle it separately.

“In many situations it is not a good prospect on site to have all this extra hardware to generate the report, so it has often been the case that this is done later back at the office, taking considerably more time. Our WinCan Embedded eliminates this and allows the report data to be generated in-the-field without all the extra hardware, leading to a very fast, simple and convenient solution. We retain our own hardware and software identity, and this is now underpinned with the recognized industry standard reporting option of WinCan.”

To make it very easy for users to export their surveys into WinCan, the Mini-Cam systems save surveys in their own unique folder with everything needed all in one place — video, stills and the WinCan generated raw data file.

This all then can be very simply imported directly into WinCan on a PC so a full report can be populated and generated automatically. This can then be checked, validated and provided to the client. Nigel closed by saying: “Our aim is always to make the Mini-Cam systems the forerunners in user-friendliness, even in seemingly complex situations. So for example if several surveys are done that are all part of one large project, these can be automatically merged together by the Mini-Cam system so all survey folders can be imported into WinCan on the PC simultaneously, to make a single report with the surveys displayed in the correct order. As a primary aim we continually look at improving on our current to make it even more user friendly. Our customers tell us that our Mini-Cam systems with in-built WinCan Embedded offer significant advantages.”

Scanprobe Ltd. managing director Jon Barry also uses WinCan Embedded. He said: “Having looked at the market and seeing the Water Companies in the U.K. using only WinCan as its reporting requirement we at Scanprobe are now looking to use this as a standard. To start with our Maxprobe system will carry the software but we will be rolling it out onto other kit over time to offer its use across several systems and capabilities. This will allow operators not currently able to offer WinCan reporting based services to parts the industry to look at doing so.

“Scanprobe has designed its own interface so as to keep its commercial identity whilst being able to ‘talk’ to the WinCan embedded software in a manner that is useable by the surveyor. Anyone using existing software WinCan but using competitor’s cameras can buy Scanprobe with WinCan Embedded and can still use the WinCan system they already hold. This means they are no longer beholden to any specific CCTV manufacturer and now have an option to use a broader spectrum of CCTV kit. This is a significant step forward for Scanprobe as we can now offer reports that meet the industry requirements in all areas. The Maxprobe also has the most up-to-date software for talking to WinCan using a powerful processor that has been designed to make it future proof against updates on WinCan such as if WinCan embedded needs to send reports to a centralized ‘cloud’ wirelessly it will be able to do so. We think this puts our system ahead of the game on this one.”

This article was provided by WinCan Europe Ltd., Woking, Surrey, United Kingdom.