NCDD Completes HDD Intersect Under the Roanoke Sound

In December 2024, North Country Directional Drilling (NCDD) was approached about an upcoming crossing to be completed under the Roanoke Sound in Nags Head, North Carolina. This was to be installed for Dare County (Department of Water). The reason for the crossing was due to failures in the previously installed water line having malfunctions. It was currently out of service.

After receiving details of the upcoming project, NCDD traveled to the site with the partnered general contractor Appalachian Pipeline. They began the planning and design phase of the crossing. NCDD took notes of the area and surveyed the topography from the entry (East Side) and exit (West side). Then they began the design phase using industry best practices for HDD. This included the calculations of the proposed product and review of the geotechnical data performed when the adjacent Washington Baum Bridge was installed. They also considered land access on each side for the layout of the product under the bridge, traveling up the West bound access to the Washington Baum Bridge Boating Access and East Bound shoulder of U.S. Hwy 64, a distance of approximately 5,200 ft.

Once the design was completed, it was proposed with a well thought out plan by North Country Directional Drilling and Appalachian Pipeline. They utilized industry best HDD practices and past experience handling crossings of this length, product type, and anticipated formations. Some would say the design and plan would be nearly impossible to successfully complete. However, NCDD put their applied experience to the test to develop the best possible plan. This plan was safe for the employees, the community, the environment, and the product planned to be installed.

The project team decided that based on the anticipated soil formations, it would be best to install a large diameter conductor casing on each side of the crossing. This was to be done prior to the pilot phase beginning. The chosen 54-in. conductor casing was determined based on the plans to oversize the bore hole to 48 in. This was 6 in. larger than the typical plan to oversize the bore hole for 30 in. product. It included additional safety factors for pulling in the plastic pipe. Along with installing the conductor casing, it was determined necessary to centralize the drill pipe and pilot tooling using a smaller diameter casing (16 in.). This would avoid the risk of making a “ledge” outside of the casing with the pilot assembly.

Due to the length, formations anticipated, and the plan to install conductor casing on each side of the HDD crossing, it was decided to utilize two maxi horizontal directional drilling rigs for the project. Each rig was supported by additional equipment on each side. This included a 9,000-gl mud system and pumps with capacity to pump upward of 800 gpm. They also had tool vans to hold tools needed for maintenance and repairs, as well as spare parts for any malfunctions with the rigs and/or equipment.

Once the casings were installed, the plan was based around the two maxi rigs drilling the pilot phase toward each other. A pre-determined intersect zone was established within the bottom tangent of the HDD design provided by NCDD. The intersect zone was anticipated during construction near the end of the bottom tangent on the East side of the crossing. This was because the West side (exit) side rig began the pilot phase first.

Once the intersect was made, NCDD pushed the drill string from the East rig to the West side pit. They followed out the West side drill string through the previously drilled pilot hole and up through the installed casing on the West side, completing the pilot phase of the HDD. When completed with the pilot, NCDD removed the centralizer casing from the West side of the crossing in preparation for the ream phase.

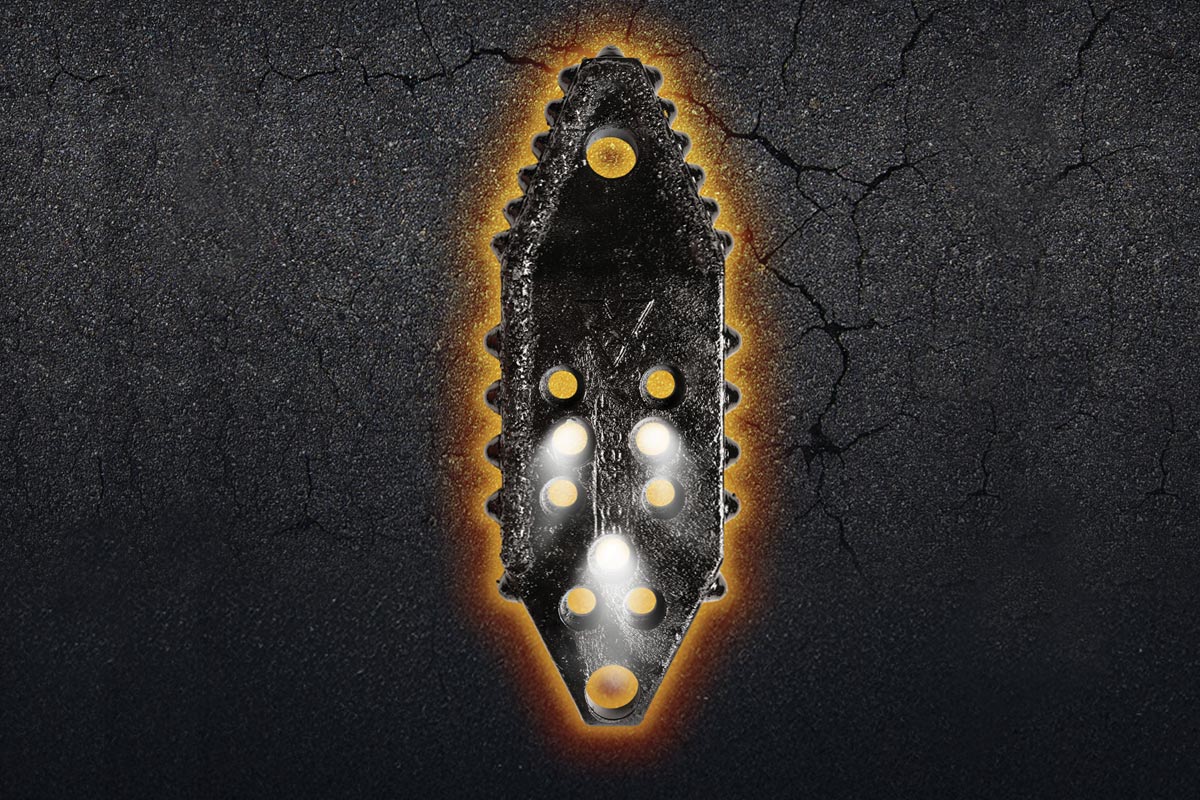

NCDD’s plans included plans to open the pilot hole to a small diameter hole. A small cutter was “reamed” from the West to the East, building a more stable and open annulus of the bore hole. This allowed the drill pipe to rotate through. When the small cutter pass was completed, NCDD began reaming the hole with a 48-in. cutting tool. It was designed specifically for the crossing and formations encountered. This tool was used to lessen the risk of the cutter digging down the bore hole’s bottom. It aimed to float as close to centralized as possible for the nearly 5,200 ft length of the HDD crossing.

While the ream phase was being performed, Appalachian Pipeline, the pipe supplier, and fusing contractor worked together. They fused the 30-in. product, as well as the 4-in. buoyancy pipe installed within the 30-in. This was done prior to the pullback phase of the crossing.

NCDD finished reaming a 48-in. bore hole ahead of schedule. It timed out to be completed when the GC and Pipe Supplier were completed with their work and tests with the product. NCDD removed the 48-in. cutter and installed a 48-in. swab tool to begin the mud/ swab pass. This confirmed the hole and removed any leftover debris from the 48-in. ream phase cuttings.

Once completed with the swab pass, NCDD began rigging down and demobilizing the West side drill rig off the location. This allowed for more workspace to bring in the product in anticipation of the pullback phase. Appalachian Pipeline assisted with handling the product and staged it in front of the West side pit. This placement gave NCDD access to hook the pull assembly to the product. They were ready to begin the pullback of the 5,200 ft of the 30-in. DR9 product.

During the pullback, NCDD used various techniques brought to the project through past experience. These minimized the pull loads of the product through the bore hole. The product was pulled up to the East side conductor casing. NCDD experienced some difficulty pulling the pull assembly up into the conductor casing. NCDD & the GC then removed approximately 15 ft of the conductor casing. They resumed pulling the product to final completion, ahead of schedule and safely with minimal pull forces.

Once completed, NCDD cleaned and demobilized all equipment, supplies, and trailers from the project. The GC assisted with the restoration of the project entry and exit points. Once the product test was complete, and the product passed required pressures and lengths for testing, Dare County and the Pipe supplier began the process of making the tie-in. This completed the project, providing a working product to supply water to the local community ahead of the busy summer season in the Outer Banks of North Carolina and Nags Head.

Josh Ugrich is president of North Country Directional Drilling, based in Bloomington, Minnesota.