NASSCO Report – Pacific Coast Highway Force Main Rehabilitation

As the community of Emerald Bay expanded in the 1960s and 1970s with homes closer to sea level, the need for a force main was necessary to convey wastewater to a City of Laguna Beach manhole located 1,700 ft from the lift station in the community.

Established in 1929, Emerald Bay is a premier gated community of 538 properties spanning both sides of Pacific Coast Highway in Laguna Beach, California.

Residents enjoy amenities that include parks, tennis, recreational programming, community beach access, community events, a volunteer fire station, and their own water and wastewater system.

Fortunately, the community leadership and engineer completing the design elected to install dual 8-in. ductile iron pipe force mains from the lift station to the discharge manhole along Pacific Coast Highway. This forward-thinking allowed for the community to have redundant force mains should one need maintenance or experience a failure.

Force Main Repair

After more than 50 years of operation, one of the force mains had a failure occur in 2021, resulting in the pipeline being removed from service for multiple months until the community could figure out a method for rehabilitation of the force main.

Because of the multiple bends in the alignment, distance between lift station and discharge manhole, extremely challenging excavation along the Pacific Coast Highway (due to blind spots along a long radius downhill curve), and pressure more than 100 psi near the lift station as a result of the 250 ft of vertical lift, technologies available for the rehabilitation were limited.

The community engineer determined that flexible fabric reinforced polymer (FFRP) was the most feasible trenchless technology method for the rehabilitation of this pipeline.

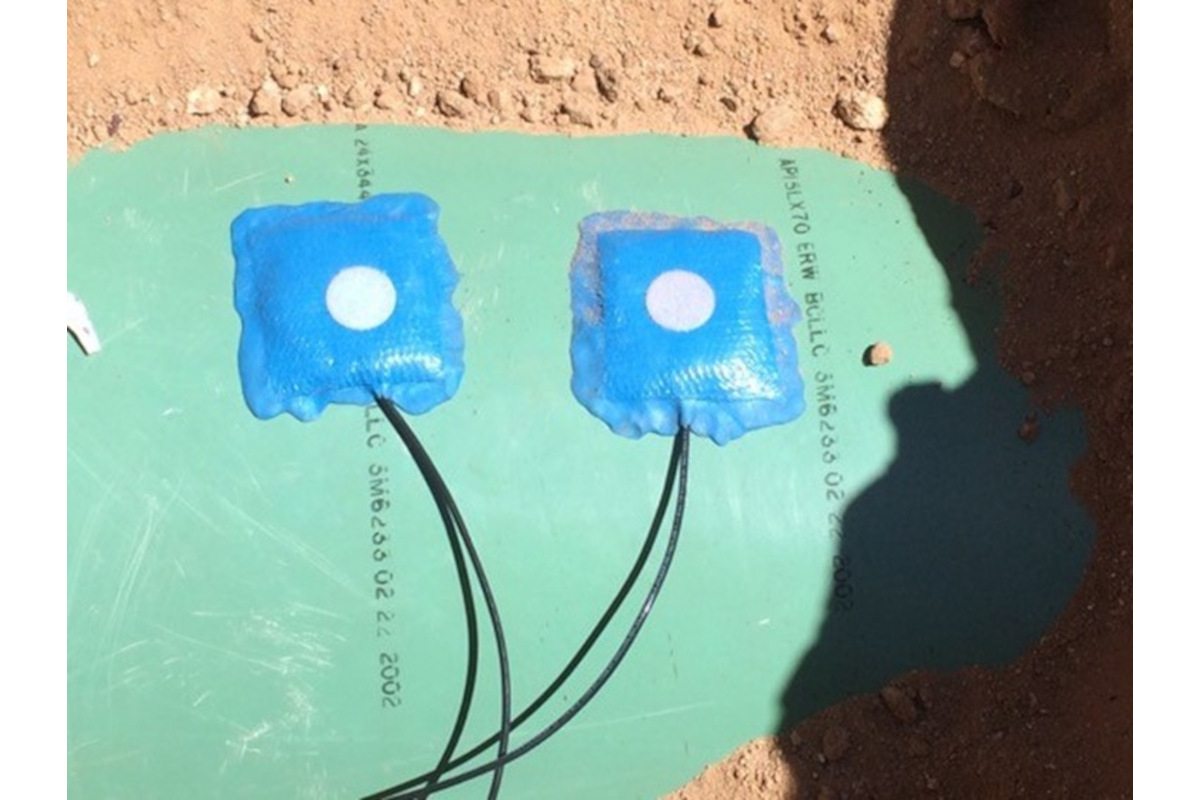

The system utilized was Primus Line, which is a polyethylene lined and coated Kevlar material that allowed for the liner to be pulled in one shot from the lift station to the discharge manhole. In addition, even when traversing bends, the liner was able to provide more than 175 psi operating pressure rating for the force main being rehabilitated.

The project was completed over a five-day period, as Cal Trans would only allow for traffic control at the discharge manhole between 9 a.m. and 3 p.m. each day. The first day of the project included pipeline cleaning, followed by pulling in rope for pre-inspection CCTV.

Day three the liner was installed, followed by termination of fittings on the fourth day of the pipeline rehabilitation. The final day of the project was for mechanical connection back at the lift station and discharge manhole.

Because of the limited permitting and excavation needed on this project, the client was pleased with the results of this rehabilitation project. There are plans for the second pipeline to be rehabilitated as funding becomes available in 2025.

To learn more about trenchless technologies, to download specification guidelines, and to view technical videos and webinars and other free technical resources, visit NASSCO.org.