How Utility Locating & GIS Mapping are Shaping the Future of Underground Construction

In underground construction, the greatest risks are often invisible. A single unmapped utility, whether it’s a gas line, water main, or fiber optic cable, can trigger costly delays, safety hazards, and regulatory challenges. In this industry, what remains unknown beneath the surface can impact both safety and the bottom line.

The era of “close enough” marking and digging is over. Today’s jobsites require more than just spray paint and good intentions. They demand precision locators, accurate geographic information systems (GIS) maps, and real-time data. As regulations tighten and mapping technologies evolve rapidly, staying informed is no longer merely a competitive advantage. It is the foundation of safe, efficient, and compliant work.

The Regulatory Wake-Up Call

Legislation is quickly transforming underground construction from a world where documentation was “nice to have” into one where it is nonnegotiable. California’s SB 865, for example, requires all new underground installations to be mapped with GIS and preserved as permanent records. It also mandates prompt reporting of utility damage to regional notification centers, which must escalate those reports to the Dig Safe Board within strict timeframes.

HDD operators can expect similar requirements to extend across other states and municipalities. Bid specifications are increasingly calling for electronic drilling records, pushing contractors to capture bore data digitally rather than relying on handwritten logs. That means it is no longer enough to simply drill a straight line, contractors must also prove it with reliable, verifiable data.

From Spray Paint to Satellites

For decades, locating underground utilities involved spray paint, handwritten logs, and guesswork. Crews marked their paint and did their best to match what was on paper to what was beneath the ground. It was a system built more on tradition than precision, and it left plenty of room for error.

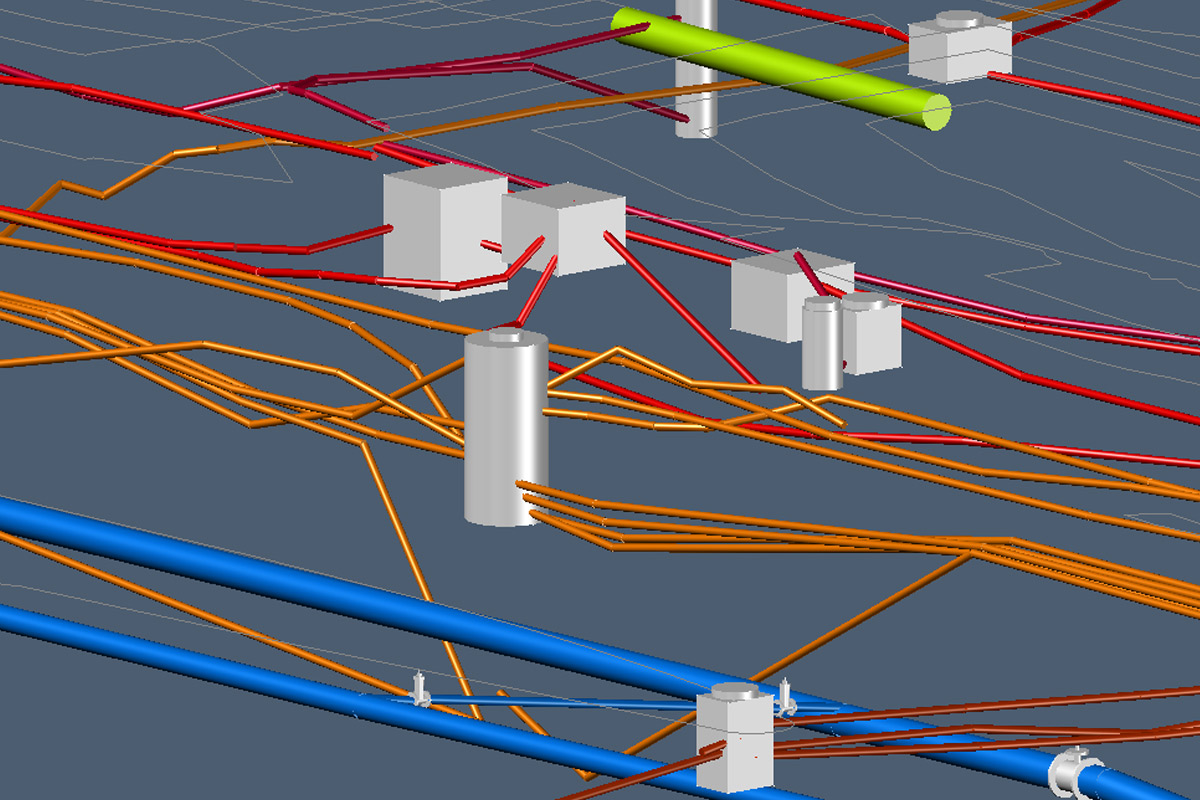

Today, utility locating is driven by technology that combines electromagnetic detection, GPS and GIS integration. Contractors can now capture the exact position of buried assets with sub-meter or even centimeter-level accuracy. Instead of just leaving behind paint marks that fade or notes that get lost, contractors can produce digital maps that are detailed, time-stamped, and easy to share.

This shift represents more than an upgrade in tools. It is a fundamental change in how information is collected, verified, and preserved. Real-time data can be uploaded directly into GIS platforms such as Esri, creating permanent digital records accessible to contractors, utility owners and regulators. This unified approach reduces disputes and improves project coordination across the jobsite.

Seeing the Unseen: The Rise of GPR

If locators are the eyes detecting metallic utilities, then ground-penetrating radar (GPR) is the X-ray vision beneath, discovering both metal and plastic utilities below. Modern GPR systems like Subsite’s GeoRanger XR Series use dual-frequency antennas to identify both shallow and deep utilities in a single pass. Add GPS integration, and suddenly an operator can walk a jobsite, watch a digital map light up with buried lines, and know exactly where to drill.

This kind of precision used to be science fiction, now it’s expected. Contractors can upload maps, layer in Google Earth, and generate visual reports that show every pipe, cable, and conduit in its place. Crews aren’t flustered and fumbling in the dark. They’re navigating with a spotlight to guide the way.

And because the latest GPR units are ruggedized with adjustable carts and multi-position antennas, they can handle jobsites from downtown to rocky hillsides. If there’s a buried obstacle, chances are it can be seen, logged, and avoided.

Telematics: The Toolbox that Talks Back

In today’s underground construction, data extends beyond the surface. Every phase from utility location to drill head navigation produces insights that enhance safety, precision, and accountability. Telematics converts machine performance data into actionable insights, supporting operations and compliance.

Telematics seamlessly integrates with utility locating and GIS mapping capturing insights like bore depth, pitch, roll, fuel consumption, buried assets, and machine performance. By consolidating this data into a common platform, contractors gain a comprehensive view of the jobsite, enabling smarter decisions, safer operations, and regulatory compliance.

In more highly regulated regions, like California and Europe, electronic drilling records are mandated by law. Telematics creates these records in real time, minimizing errors and eliminating manual logs. The same systems that ensure timely project completion and efficient equipment operation also meet larger documentation standards.

Data as a Crewmember

On today’s jobsites, data is as essential as any piece of equipment. By integrating utility locators, drill telematics, and ground penetrating radar into a cohesive system, contractors gain comprehensive visibility throughout the entire drilling process – pre, during and post bore.

Pre-Drill Planning: Crews accurately map congested easements, reducing costly and dangerous cross bores.

During the Bore: Depth, pitch, and roll are tracked in real time, recorded with GPS to ensure accuracy.

Post-Bore: As-built profiles and electronic records are generated in multiple formats, ready for archiving or sharing without re-entering data.

This information flow is more than just record keeping, it’s a road map guiding projects from planning to completion, ensuring efficiency and accountability, and increasing safety at every step.

GIS Mapping & Unified Systems Working Together

GIS systems with platforms like Esri, serve as the backbone of underground infrastructure records. By channeling field-collected data directly into GIS maps, contractors and utility owners maintain a unified, permanent record of underground assets. This approach archives data securely in one location, creating a living record instead of a one-time report. Utility owners and municipalities develop comprehensive views of their assets, while contractors reduce guesswork, mitigate risks, and confidently demonstrate compliance.

As cloud-based systems expand, the potential extends beyond individual projects. The industry is moving towards regional, statewide, and eventually nationwide mapping systems, providing consistent, reliable visibility underground. What once seemed aspirational is becoming a reality, reshaping how underground construction is planned, executed, and regulated.

The Bottom Line

The true value of data shines in its interconnectedness. Without integration, data remains ineffective, losing potential in isolation. The magic lies in their unity.

Picture a crew at dawn, armed not just with tools but with technology: locators communicating with GIS, drills linked through telematics, radar revealing the earth’s secrets. Every data point becomes a brushstroke on a digital canvas, mapping our underground world, not just smart technology, but efficient and future-proof.

With stricter regulations and advancing technology, the days of pencil sketches on napkins are over. However, this shift is not a burden but an opportunity. Advanced locating, mapping, and telematics tools empower crews to work safely, efficiently, and confidently. They can secure bids, adapt to evolving regulations, and maintain profit margins.

As the saying goes, “measure twice, cut once.” Today, this evolves to “locate once, map forever.”

Rodolfo Cabello is a Subsite product manager.

- How to Prepare and Trowel-Apply for a Manhole Rehab Project

- Melfred Borzall’s Tri-Con™ System: Faster Changeovers. Stronger Connections. Built for the Realities of HDD.

- Engineered HDPE Solutions for Trenchless & HDD Projects

- Microtunneling Short Course Owner Scholarship Program now Open

- IQuip Introduces the BOOST HDD Support Truck

Next Up

2026 CUIIC Academy Spring Summit | March 3-5, 2026 | Mississauga, Ontario | Learn more