How to Create a Proposed HDD Bore Plan

Preplanning is used in all aspects of the horizontal directional drilling (HDD) process. Whether it is planning the jobsite layout or the restoration, there should be a plan for it. One area that is commonly overlooked is creating a rod-by-rod bore plan.

Before you begin

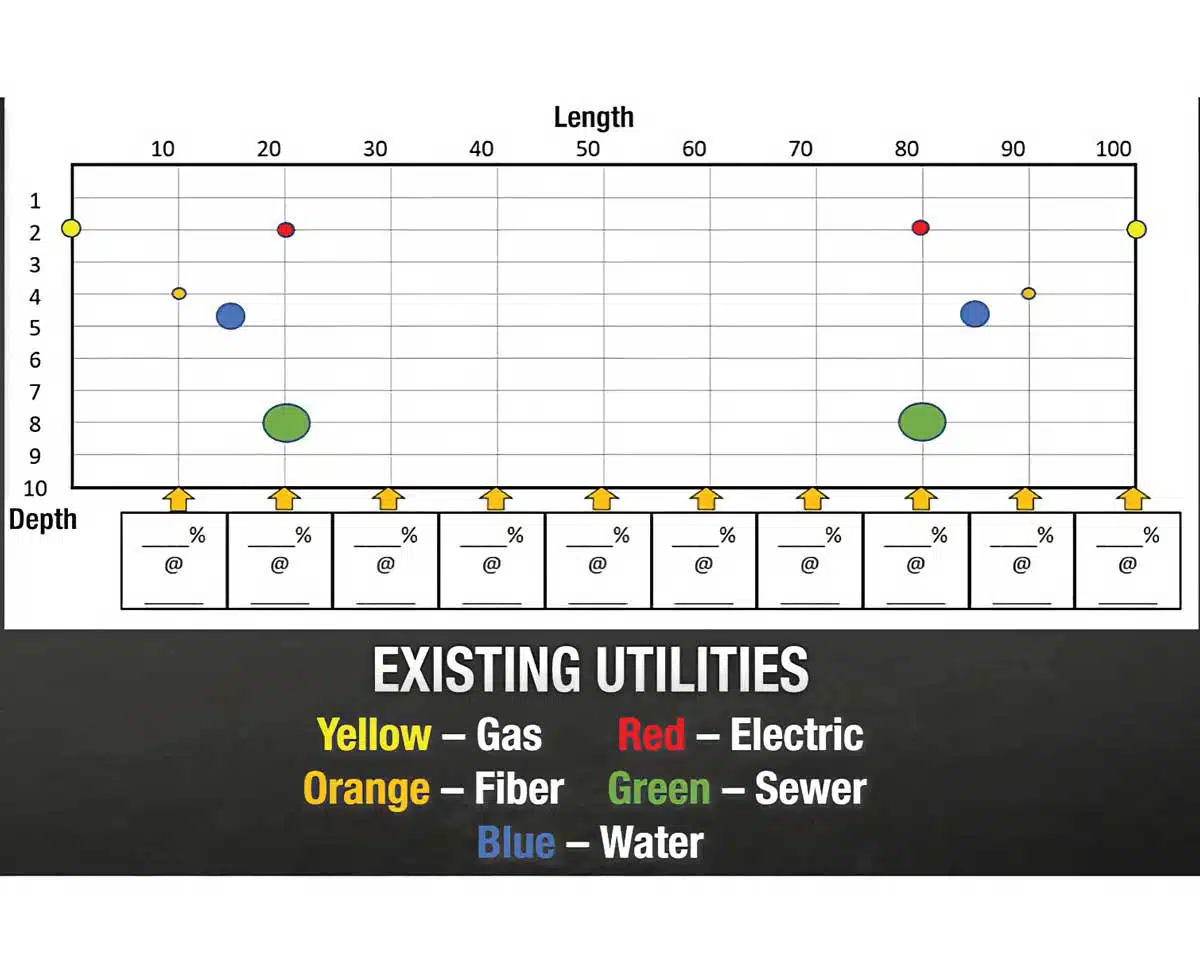

Before creating the proposed bore plan, it’s important to know the location and depth of existing utilities and jobsite parameters. Knowing this helps you understand what to avoid and where to bore. This may include the clearance needed around utilities and the desired depth of the new utility. If reaming is required, make sure to increase the utility clearance during the planning process.

Calculating your rod-by-rod plan

The Vermeer D20x22 S3 horizontal directional drill with a 10-ft (3-m) rod and a maximum bend of 9.8% (rounded to 10% for quick math) will be used for this example. With this information and jobsite parameters, such as existing utilities and jobsite specifications, you can now start calculating a simple rod-by-rod plan on a piece of graph paper.

Here’s what you’ll be working from:

Bore parameters:

- A 100-ft (30-m) long bore

- Approximate depth of 5 ft (1.5 m)

- Maintain a 1.5-ft (.45-m) clearance around all utilities.

- The drill is on level ground with a drill head position or angle sitting between -20% and -30%.

- Start this proposed bore plan with the first rod at -25%.

To calculate the first rod depth, multiply the 10-ft rod by the current pitch of -25% (10 ft x -25% = x). This equals -2.5 ft (-0.8 m), which is the approximate depth change of the drill head once the full rod has been drilled into the ground.

Now, draw the first rod on the graph starting at the corner of the graph paper and go down approximately 2.5 ft (0.8 m) and over 10 ft (3 m) and make a dock. This represents the approximate depth of the drill head at the completion of the first rod. You can include the predicted depth and pitch to help you know how much you can change on the next rod. Since the drill head is at a -25% pitch, the maximum rod bend of 10% allows a change down to -35% or up to -15%.

Next, decide what depth you need to be at the end of rod two, then figure out what pitch will get you there. For example, to get to 4-ft-deep (1 m) at the end of the second rod, you’ll need to go 1.5 ft (0.5 m) deeper. If you multiply the 10-ft rod by -15%, it equals -1.5 ft.

After you draw that rod, write down your current depth and pitch. Now, say that you want to be level at 5-ft-deep (2 m), which leaves two more rods to achieve that depth. On rod three, change the pitch to a -10%, which will result in a 1-ft depth change, bringing the depth to 5 ft. Now, on the fourth rod, you can go to a 0% pitch to stay approximately at 5-ft deep.

Knowing that it took four rods to get down to 5 ft and level, you’ll maintain a 0% pitch for rods five, six and seven.

It is best practice to have your bore path enter and exit at approximately the same pitch angles. So that means on rod eight, you’ll start gradually coming up. Knowing that you want to be at 4 ft at the end of this rod, a depth change of 1 ft (0.3 m) is needed. To achieve this, you want to end this rod at a positive 10%.

For rod nine, you want to end at a depth of 2.5 ft. Having 1.5-ft depth change requires an ending pitch of positive 15%. The parameters of this bore were to exit the ground on the 10th rod. The current depth is 2.5 feet at a positive 15%. To exit the ground at the end of this rod, a 2.5-ft depth change is needed. A positive 25% pitch results in 2.5-ft depth change.

Drawing the last rod on the graph shows that at a positive 25% pitch you’ll exit the ground at the end of the 10th rod. And your HDD bore plan is set.

Vermeer Corporation reserves the right to make changes in engineering, design and specifications; add improvements; or discontinue manufacturing at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region. Please contact your local Vermeer dealer for more information on machine specifications. Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries.

© 2023 Vermeer Corporation. All Rights Reserved.

Provided by: Vermeer Corporation