Crossing the Kiskatinaw River: HDD Project Exhibits the Importance of Dedication and Team-Oriented Mindset

NOVA Gas Transmission Ltd. (NGTL), a wholly owned subsidiary of TC Energy, recently completed the construction of a new pipeline and associated valve sites in the Dawson Creek area of British Columbia.

The pipeline, known as the Groundbirch Mainline Loop (Sunrise Section), included 23.5 km of NPS 42 (1,066.8 mm O.D.) mainline and tie-in facilities from Groundbirch to Arras, approximately 28 km northwest of Dawson Creek.

As part of the project, the NPS 42 pipeline alignment crossed the Kiskatinaw River, which had to be crossed utilizing trenchless methodology. The crossing location was within a rural area approximately 25 km northwest of Dawson Creek, British Columbia, and both Direct Pipe installation (DPI) and horizontal directional drilling (HDD) crossing methodologies were considered.

Site Challenges

At the project site, the Kiskatinaw River is approximately 40 m wide and flows from south to north through a significant valley that is approximately 470 m wide and 30 m deep. The valley bottom terrace extends for about 120 m southwest and 200 m northeast of the river channel before the terrain rises to the top of the valley slope.

During the preliminary design stages, a geotechnical investigation was conducted which included three boreholes and a geophysics survey. An anomalous zone of high resistivity was identified with the geophysics survey on the east side of the crossing, and an additional borehole was completed to further identify the geotechnical conditions. The investigation found stiff to hard low to medium plastic clay, silt, sand, and gravel layers in the area. Clay shale bedrock with interbedded varying strength sandstone layers was found to underlie the surficial materials. In addition to the boreholes, electrical resistivity tomography (ERT) and seismic refraction were also used to assist in identifying the bedrock interface. Based on the geotechnical data, the HDD was designed to pass through cohesive soils and bedrock, lending to a highly feasible crossing.

Preliminary designs were completed in January of 2019, with the review process, including third-party design reviews, continuing until August 2019 when finalized Issued for Construction (IFC) drawings were completed.

The Final HDD Design

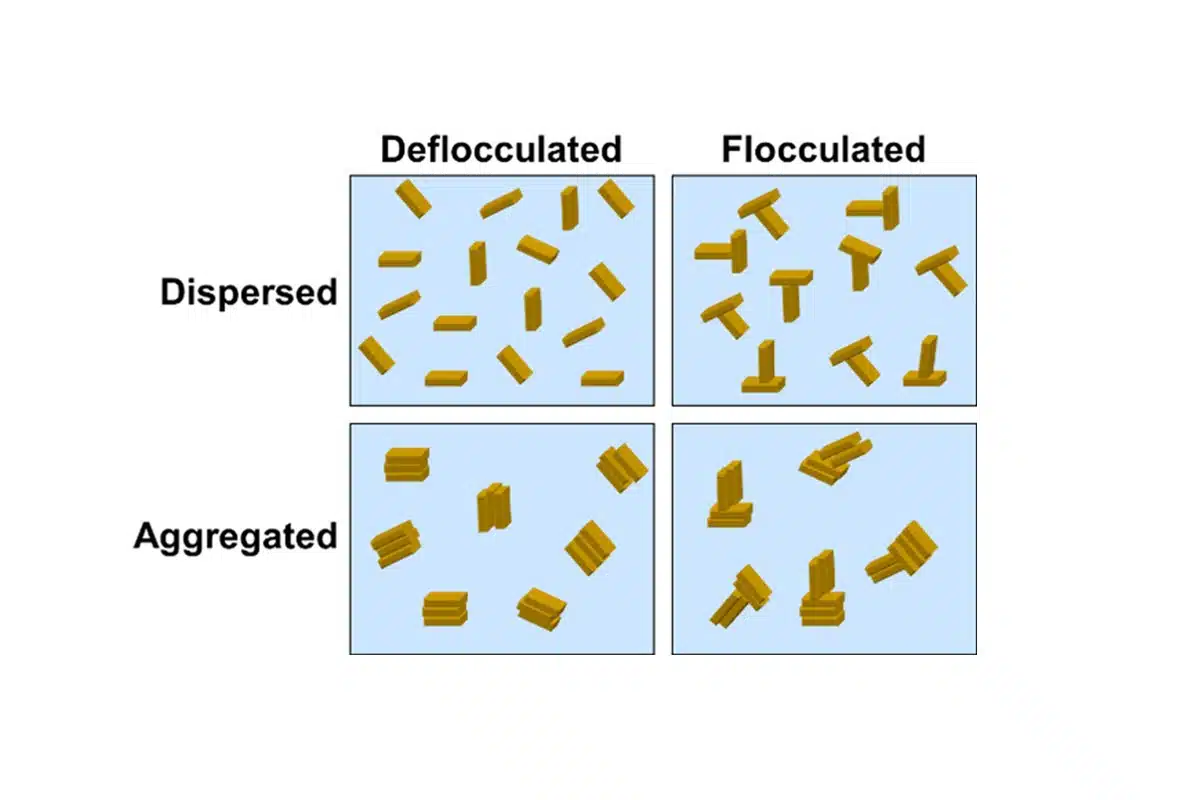

The final design comprised a 1,197 m crossing of NPS 42 high grade steel pipe, and it was estimated that the required installation pull force would be around 326,000 lbs, including the use of buoyancy control. Buoyancy control, when used for HDD installations, requires filling the HDD section of pipe fully or partially with water to create a near-neutral buoyancy within the drilling fluid, in turn reducing expected pull forces.

The design included an 18-degree entry angle and 40 m of NPS 66 (1,676.4 mm OD) on the west and a 12-degree exit angle and 20 m of NPS 66 casing on the east. The casing was required to isolate the borehole from the surficial soils and reduce the risk of fracture to surface, but also necessitated the use of intersect methodology for drill completion. The intersect methodology also assisted in reducing the risk of fluid release, and the intersect was planned within a 100 m long section of the HDD bottom tangent. CCI proceeded with design optimization and several specification updates and issued a revised IFC HDD design in May 2021.

The design included a pullback plan which consisted of a single section of pipe laid out along the ROW and temporary workspace east of the river. The combination of the 12° exit angle and large pipe size resulting in a maximum overbend height of approximately 8 m and required 7 cranes and 1 side boom for support.

As construction drew closer, CCI also provided assistance developing casing shoe designs and a detailed pull force table in response to Contractor requests for additional pull force analysis at 50 m intervals and at varying drilling mud weights.

The planned construction duration was 88 days, including mobilization, demobilization, and surface casing installation and extraction.

Trenchless Work Commences

Surerus Murphy Joint Venture (SMJV) was selected to act as the Prime Contractor for the project, while The Crossing Company was chosen as the trenchless contractor to complete the HDD. Two rigs were to be mobilized and utilized for drilling operations to complete the installation of the NPS 42 pipeline based on the intersect methodology proposed. The Crossing Company used Rig 11 — an American Augers DD-1100RS drilling rig with 1,200,000 lbs push/pull force and 100,000 ft-lbs of rotary torque — as the primary rig at the entry location. Additionally, Rig 5 — an American Auger DD-220 custom engineered rig with 220,000 lbs push/pull force and 60,000 ft-lbs of rotary torque (with integral freewheel) — was used to provide exit side support. CCI was engaged for on-site HDD construction inspection to oversee the construction progress and to support drilling waste disposal activities.

Mobilization began in October 2022, and The Crossing Company and SMJV began installing the NPS 66 surface casing on exit utilizing a pneumatic hammer until refusal. The total installed length was 24.3 m, 4.3 m shorter than the design, but seated into a competent formation as intended. On entry, casing was installed to 25.71 m, an additional 0.65 m of casing was installed in 2.5 hours, and the decision was made to mobilize a hydro-hammer from The Tunnelling Company to assist with installation. On Nov. 3, Section 3 of the casing was welded and hammered to a depth of 34.78 m. Finally, The Tunnelling Company completed the entry surface casing installation with a total length of 40.37 m.

The drilling activities began with the 12.25-in. pilot hole on the exit side of the crossing while the casing installation activities and mobilization of drilling equipment were being continued on the entry side. Before the intersect attempt, radar readings indicated that the entry side bit was 1.33 m above and 0.02 m to the left of the exit hole, requiring the borehole to be shaved and reworked for proper alignment. Finally, the intersect was completed around 925 m MD. The Crossing Company continued working on the transition zone using both the entry and exit rigs until they achieved the proper azimuth for the intersect.

On Nov. 25, The Crossing Company started reaming operations with a 30-in. TCI reamer and made progress ranging from 38 m to 93 m per day over several days. During reaming, the reamer was worn and needed replacement, at which time The Crossing Company swapped it for a 42 in XTR TCI reamer and continued reaming to 492 m MD. On Dec. 16, they tripped out the 42 in reamer and removed the drill string from the hole, emptying tanks, draining down, and winterizing the rigs before demobilizing for the Christmas break.

The Crossing Company returned to the site on Dec. 28 and resumed reaming operations, but high rotary torque was observed, prompting The Crossing Company to install a 24 in XTR reamer and then a 30-in. reamer to rework the particular section of the borehole. Once the conditions were deemed adequate, the 42-in. reaming operations were completed, but while tripping back, rubber from inside the kelly hoses was lodged in three of the five jets, causing poor hole cleaning. The Crossing Company replaced the kelly lines and added a 54-in. reamer to the drill string, progressing relatively smoothly with a few choppy sections between 348 m and 410 m MD. The rig generators on both the entry and exit side experienced some issues, causing delays in completing the reaming operations.

Installation Complete

The NPS 42 line was successfully installed on Feb. 15, 2023, experiencing a maximum pull force of 403,000 lbs. The entry and exit casings were both successfully removed, and all drilling waste was disposed of as per applicable regulations. All personnel involved in the project exhibited dedication and a team-oriented mindset, which was crucial for seamless collaboration between contractors on site, resulting in successful completion of the crossing.

Alexandre Dumas, E.I.T., is a junior project manager at CCI Inc.