‘Grout First,’ Right Answer to Solve Sullivan’s Island, S.C., I/I Issues

The condition assessment clearly indicated 90 percent of Sullivan’s Island problem was high infiltration and inflow (I/I) and 10 percent structural. Conventional wisdom suggests attacking structural issues first, but Gress thought otherwise and found an engineer who agreed with him.

RELATED: Trenchless Technology Magazine Announces Its 2015 Top 50 Trenchless Design Firms

James Shelton, vice president buried infrastructure for ARCADIS, sought to attack the problem at the source — excessive I/I — which was the underlying cause of the structural defects and here’s why:

• destabilization of the pipe bedding

• soil and sand reducing capacity

• SSOs from the collection system

• High flows at the WWTP

• Risk of effluent violations

Gress and Shelton weighed cost and technology alternatives for controlling I/I. Both had previous knowledge and experience with municipal grouting. Both attended grout schools to advance their understanding of methodology and supporting procedures. Their conviction for the low-cost, high-reward advantages of injection grouting led to a “grout first” approach with an innovative construction manager at risk (CMAR) delivery method.

The plan was to attack I/I holistically at all points where infiltration exacerbates system efficiencies and longevity. Credit to the foresight of Gress, he knew once the main’s, laterals and lateral connections were sealed, the groundwater table would rise and enter the system higher through the manholes.

For years in advance, on a limited budget, he and his staff adopted a top-down approach and reconstructed, resealed 200 of 325 manholes. The wisdom proved invaluable.

Phase 1 of the project focused on high-priority basins 5 and 6. A total of 38,000 ft of mainlines and the first 7 ft of the laterals and lateral connections were sealed with injection grout in order to control infiltration. Additionally, 1,900 ft of mainline was CIPL lined and eight cured-in-place pipe (CIPP) point repairs due to structural defects.

RELATED: Urethane Grout Answers the Call for Creative Problem Solving

The result exceeded even Gress’ and Shelton’s expectations: reduced wet weather flow to the rehabilitated basins — 37 percent, I/I reduction — 46 percent. This was the encouragement Town Council needed to fund the next step of the three-phase program.

Phase 2 is now set to begin in October 2016 focused on Basin 3 for mainlines and lateral connections, but this time, the length of lateral sealing will extend to the property right of way versus the first few feet from the mainline.

Sullivan’s Island is divided into six basins, from left, 1, 2, 3, 6, 4 and 5. Phase 1 of the project focused on the high priority basins — 5 and 6 — and Phase 2 is set to begin in October 2016 and will focus on Basin 3.

Major problem solved, new one created

Sullivan’s Island is a coastal community with 2,000 year-round and seasonal residents, as well as tourists who come to visit the historic attractions. Rain events today now have new meaning. Previously, stormwater runoff was aided by the porous sanitary system, which swept away surface and groundwater to the wastewater treatment plant at high-expense to the ratepayer. Now, standing water after a rain event is visible proof-positive of a sealed collection system. Stormwater management is the responsibility of Charleston County and Gress is working with those authorities on a study to resolve this new bittersweet issue for island residents and visitors.

Validation of Insights, Assumptions and Beliefs

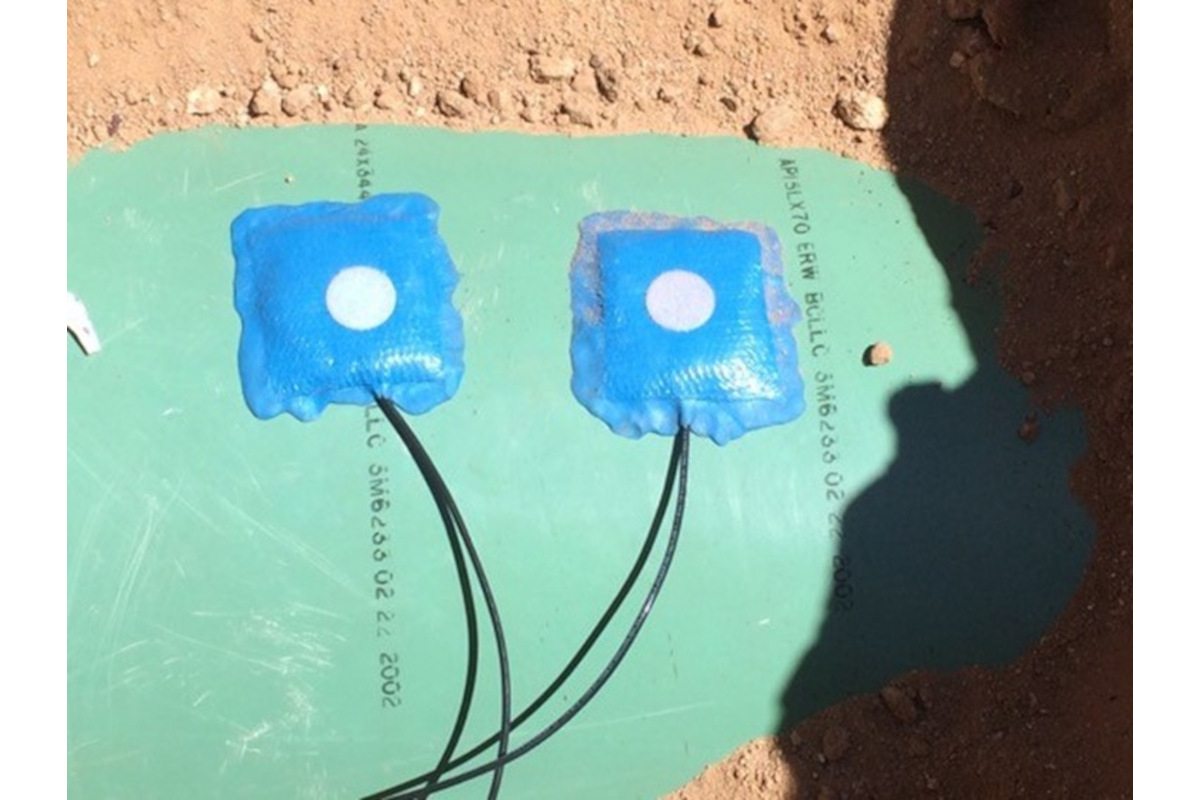

Shelton’s experience determined the single biggest impact on the design life of grouting was not the grout, but the quality of installation. With the CMAR delivery method, ARCADIS assumed the majority of risk and adopted a highly collaborative working relationship with the primary grouting contractors (Bio-Nomic Services, Aqua Tri-State Grouting), technology vendor (Logiball) and material supplier (Avanti).

An onsite construction manager was present throughout the project; she and Shelton proceeded to question every process and procedure working with the field staff and technology providers to optimize the execution with constant focus on effectiveness and longevity. From this experience, new insights on engineering specifications, field implementation and new tooling to extend the reach of grouting are raising the bar on injection grouting and leading to new standards of operation:

1. Testing and packer pressures

2. Grout concentration

3. Use of latex as an additive

4. Gel times and temperature impact

5. Pumping rates

6. Stage and defect grouting

7. Pull-back and warranty tests

Shelton’s belief in onsite inspection is key-critical to ensure engineering specs are executed precisely by the contractor. To that end, he’s the principal designer of an upcoming 2017 program from NASSCO’s Inspector Training Certification Program (ITCP) specifically for injection grouting.

RELATED: NASSCO Marks Its 40th Anniversary

Gress’ observations that the cleaning and jetting of sanitary sewers actually pulls in more sand and advances conditions for more infiltration, he was adamant about grouting immediately after jetting the lines. Shelton honored this request and built it into the step-by-step procedures and sequence of events for all five grouting crews on this project.

Sealing the collection system provided a bittersweet result: standing water after a rain. Previously, stormwater runoff was aided by the porous sanitary system, which swept away surface and groundwater to the wastewater treatment plant at high-expense to the ratepayer.

Multiple Success Factors

If there was only one word that defined multiple success factors contributing to this project, the word is ENGAGEMENT.

Both the owner and engineer were vested in a positive outcome and the engineer-construction manager approach clearly defined risk and responsibilities, but the spec was challenging and required the contracting organizations to re-think everything they knew about injection grouting. The owner, engineer, inspector, contractor, technology and supplier relationships were all challenged, but their engagement for the greater good of the project, the grouting industry, and ultimately every municipal stakeholder led to several important improvements and proofs for the industry.

In many respects, this project led to new knowledge, new technologies, new practices and gave birth to the next generation of injection grouting standards. Bold statement, but unless you were there, unless you personally witnessed the spirit of cooperation, the leadership, and the engagement of all parties working as one, you’ll have to accept this story as gospel knowing there’s now a better solution to infiltration, that when executed properly, is both cost-effective and enduring.

Beyond Sullivan’s Island, “grout first” can be the most cost-effective I/I solution for other communities and sewer districts choosing to be proactive prior to requiring more costly structural repairs. In the name of sustainability, in support of trenchless technologies, and in defense of ratepayers everywhere, injection grouting deserves thoughtful consideration from municipal stakeholders and consulting engineers.

Don Rigby is vice president of marketing and education at Avanti.