East River Crossing Pushes Boundaries, Results in Record-Length HDD

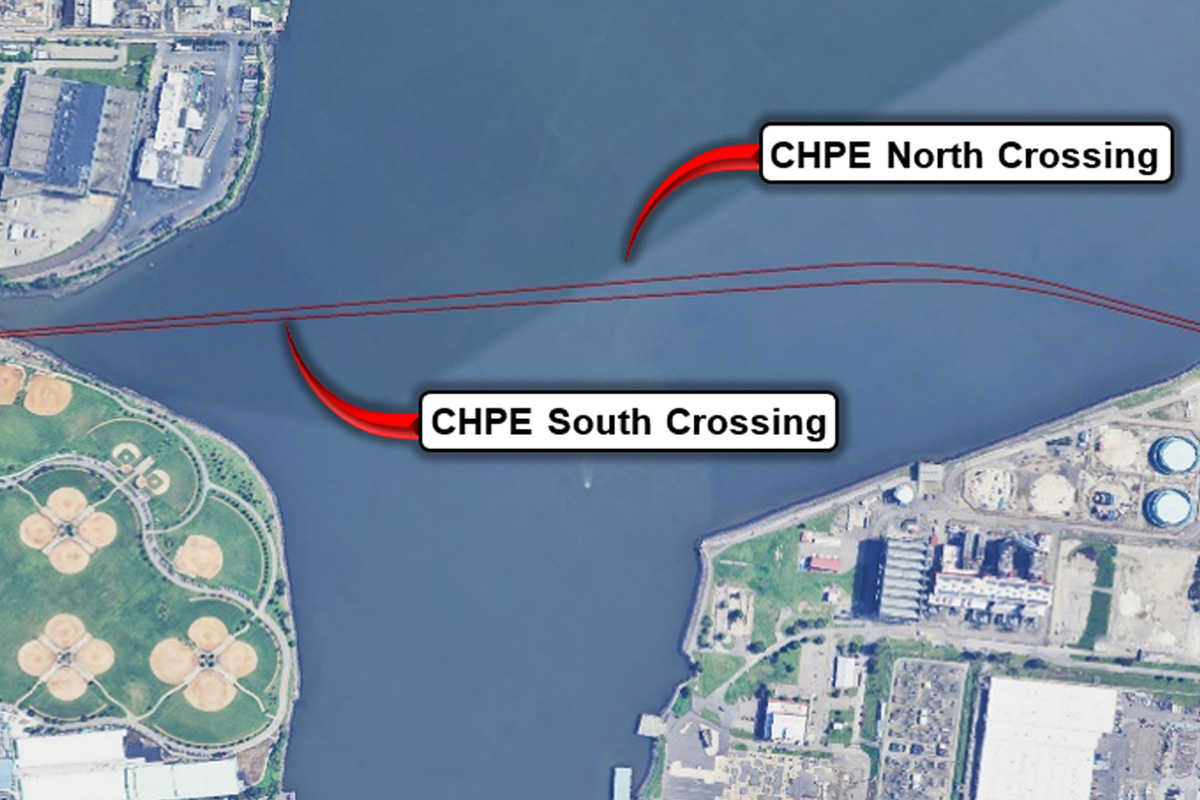

Among the most technically challenging installations on the Champlain Hudson Power Express project were two crossings at the East River.

Project Background

The Champlain Hudson Power Express (CHPE) project is a transformative energy infrastructure initiative. It is designed to deliver clean, renewable hydroelectric power from Canada to New York City. Spanning 339 miles, the 400kV high-voltage direct current (HVDC) transmission line includes both underground and submarine segments. Of the 146-mile terrestrial route, trenchless construction played a vital role in navigating complex urban and environmental constraints.

The two parallel horizontal directional drills (HDDs) beneath the East River are each approximately one mile in length. These HDDs were not only the longest on the CHPE project, they also represented a first-of-its-kind installation using Permalok steel casing. This is a mechanical interlocking pipe system designed specifically for trenchless applications.

Michels Trenchless was selected to execute the HDDs. This decision was based on the complexity of the crossing and their proven track record of successfully completing challenging and record-breaking trenchless installations. To solve workspace and pipe stringing limitations, Michels proposed using Permalok casing. This enabled the successful completion of a 5,100-ft HDD despite having no available pipe stringing area. This set a new record for the longest HDD installation ever completed using Permalok casing. The combination of length, complex geology, and constrained urban workspace made this a standout achievement in trenchless construction.

East River Layout

The crossings involved pilot hole drilling from both sides of the East River. It started at Randall’s Island and the ConEdison site in the Bronx and intersected near the center of the alignment. The installation required 20-in. steel casing to sleeve conduits for 10-in. and 4-in. DR14 FPVC pipes carrying cable and fiber. The soil profile presented a mix of urban fill, estuarine deposits, and hard, abrasive Fordham Gneiss bedrock, with soil cover ranging from 40 to 120 ft.

Steel casing was used due to the presence of a fault and shear zone in the bedrock. This posed risks to the conduits from both short and long-term geological loading. Just as importantly, the casing enabled the successful pullback of the 10-in. and 4-in. FPVC conduits through the installed casing, rather than directly through the HDD borehole. It was believed the conduits would not survive the installation loads if pulled one mile through an open borehole. Especially given the abrasive and irregular subsurface conditions. By installing casing first, the project team significantly reduced pull forces and provided a protective barrier that shielded the conduits from potential damage. This dual-purpose approach, providing both physical protection and reduced installation stress, was essential to the success of the installation and the long-term integrity of the transmission line.

Permalok Steel Casing

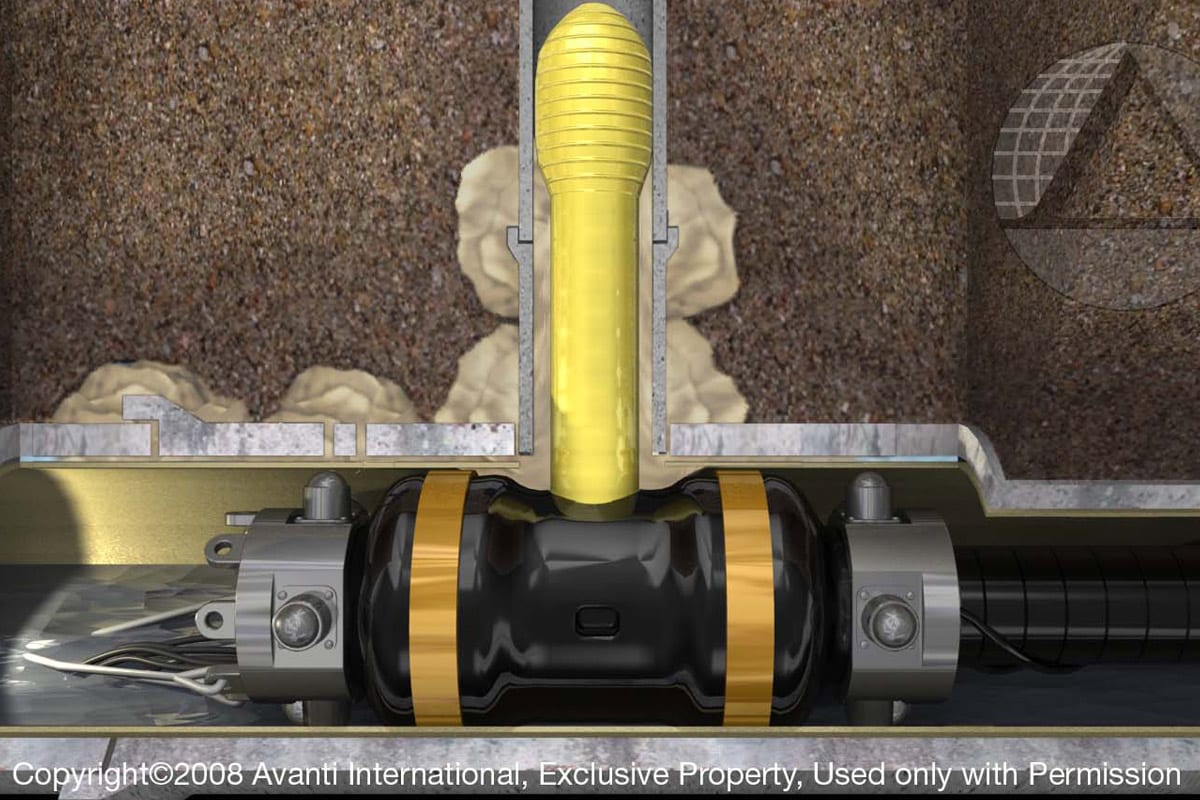

To overcome the site constraints, Michels implemented the use of Permalok steel casing with a mechanical interlocking system. This system eliminates the need for welding. Permalok is specifically designed for push applications in trenchless installations. It has joints that are flush with both the interior and exterior surfaces of the pipe. For this application, the HDD joint profile was used, which incorporates precision-machined interlocking teeth located on both the male and female portions of the joint. These features increase pull-apart resistance while allowing the joints to engage with minimal force. For this installation, the pipe was custom-manufactured in 30-ft sections. This was done to fit on top of the drill rig, enabling a “stovepipe” installation method. This approach allowed the casing to be installed section by section directly from the rig. It eliminated the need for pipe string-out and enabled efficient advancement in constrained urban conditions.

The joint is not designed to be pulled in tension, only to withstand compression. However, to push pipe a mile, Michels aimed to keep the pipe in tension using the drill rig on the west side. There was no data available to determine how much tension the joint could safely withstand before separation. Therefore, Michels conducted its own R&D.

Six full-scale joint load tests were performed at their facility in Lomira, Wisconsin. Using a specially manufactured jig on an HDD drill rig, two Permalok pipe sections were aligned, connected, and restrained with an in-house apparatus. The pipes were then pulled straight or bent beyond the design radius until joint separation occurred. Electronic Data Recording (EDR) documented the tensile forces applied during each test.

Based on the test results, the project team reached a consensus on a safe pull force. This was needed to ensure the joints did not separate during installation.

In the Field

As the pipe was pushed from the east side, the drill rig on the west side simultaneously applied pull force. This was done to keep the pipe in tension throughout the installation. This coordinated push-pull method was essential for maintaining joint integrity. Additionally, it ensured smooth advancement of the casing.

Coordination between crews on both sides of the East River was critical, as they had to work in tandem to synchronize thrust and tension operations. To safeguard the Permalok joints, the pull rig’s maximum tension limit was set on the drill rig to ensure the safe value was never exceeded.

The installation was completed in five shifts. It had an average production rate of approximately 1,000 lf per 10-hour shift for both HDDs. Traditional butt-welding requires 90 to 120 minutes per joint, but Permalok connections took only five to seven minutes each. This efficiency translated into a schedule savings of one to two months for casing installation alone.

The maximum thrust measured during installation aligned closely with the calculated inverted tension from an equivalent pullback scenario. This further validated the viability of the push method.

Pushing the Boundaries Benefits the Project

Beyond time savings, the use of Permalok offered significant environmental and cost benefits. On Randall’s Island, the push installation method eliminated the need for extensive tree trimming and removal. This preserved the natural landscape and reduced ecological impact. The streamlined installation also minimized disruption to the active tank farm on the east side, allowing construction to proceed without interfering with ongoing operations. The cost savings associated with reduced labor, equipment, and schedule compression were substantial.

The success of this record-length, first-of-its-kind push installation of Permalok casing for HDD applications underscores the importance of innovation and collaboration in trenchless construction. Michels’ proposal to use Permalok demonstrates exemplary problem-solving and teamwork across project stakeholders.

The CHPE East River crossings not only set a new benchmark for HDD installations. They also showcased how adaptive engineering and innovative materials can overcome even the most complex site constraints.

- EnviroCure-Felt Technology Receives U.S. Patent

- Oatey Co. Promotes Kelsey McMillan to VP, Cherne Global

- Getting HDD Locator Calibration Right

- Cured-in-Place Pipe Rehabilitation Testing – Ensuring Quality and Longevity

- Derek Potvin, P.Eng, Is the 2026 NASTT Hall of Fame Inductee

Next Up

HDD Academy | February 19-20, 2026 | Scottsdale, Arizona | Learn more

2026 CUIIC Academy Spring Summit | March 3-5, 2026 | Mississauga, Ontario | Learn more