2025 Trenchless Technology Rehabilitation Project of the Year Runner-Up

99 Avenue Sanitary Trunk Rehabilitation – Stage 2

The 99 Avenue Sanitary Trunk Rehabilitation – Stage 2 project involved the structural rehabilitation of 1.1 km of a monolithic concrete, arch-shaped sanitary trunk sewer. It was located approximately 30 m below grade in Edmonton, Alberta, Canada.

Constructed in 1966 using hand tunneling with steel arch ribs and timber lagging, the original trunk featured a cast-in-place cross section. It was approximately 1,200 mm in span by 1,900 mm in rise, formed using internal slipforms.

As a critical conveyance element within Edmonton’s sanitary trunk network, the 99 Avenue trunk receives most of the flow from the city’s western neighborhoods. After more than 50 years of service, significant deterioration occurred due to hydrogen sulphide-induced corrosion. This prompted the need for a technically robust rehabilitation strategy.

Project Background

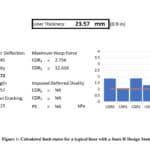

The design-build rehabilitation method involved sliplining discrete segments of fiberglass reinforced polymer mortar (FRPM) liner pipe, manufactured by HOBAS Pipe USA, into the existing trunk. The liner featured a non-circular profile. It measured 950 mm in span by 1,400 mm in rise, specifically designed to optimize hydraulic performance and structural fit within the existing geometry.

Installation was performed via worker-entry from two purpose-built access shafts, with maximum insertion lengths reaching 500 m.

Between August 2024 and March 2025, a total of 442 FRPM pipe segments — ranging from 0.61 m to 2.44 m in length — were manually inserted and joined in situ. Each segment was temporarily secured using timber blocking to resist flotation during grouting. The annular space was subsequently backfilled with over 800 m³ of low-viscosity cementitious grout.

The annular grouting operation was executed in 18 controlled sections, ranging from 12 m to 75 m in length. These sections were isolated using cast-in-place bulkheads. Grouting was conducted from within the liner, utilizing pre-cored holes to facilitate groundwater removal, grout injection, and venting. Following grouting, all cored penetrations were sealed. Also, any joints exceeding the allowable angular deflection tolerances were field laminated to restore structural continuity and ensure long-term watertightness.

This technically demanding project demonstrated the successful integration of trenchless rehabilitation techniques within a deep, critical urban sewer asset. It managed to maintain service continuity and minimize surface disruption.

Why Project Is Outstanding

This project exemplifies technical excellence and innovation in the face of complex constraints. The project team addressed numerous challenges, including limited as-built records, restricted access, and variable trunk geometry and alignment. There was also a high groundwater table contributing to significant infiltration. These conditions demanded an adaptive and multidisciplinary approach to design, inspection, and construction execution.

Access was limited to two existing manholes located at the extents of the rehabilitation scope. The downstream manhole was offset from the trunk alignment. Despite this, the project team successfully completed initial flushing, cleaning, and multi-sensor inspection (MSI) from these locations under live flow conditions, covering approximately 500 m in both directions. As full-length inspection was not feasible, the resulting 3D MSI datasets were stitched together. They provided a composite model of the trunk’s interior geometry, informing the preliminary rehabilitation design.

Verifying Location

To verify the true location of the trunk for access shaft siting, an array of vertical boreholes was drilled across the assumed alignment. The presence of the tunnel was confirmed based on depth and the retrieval of timber lagging in the drill cuttings. Once the shafts were constructed and the trunk isolated, a second round of cleaning was performed. This was followed by direct engineer entry for a detailed condition and safety assessment. It included both destructive and non-destructive testing, along with comprehensive visual inspection.

Tunnel Survey

Upon confirming safe access conditions, a conventional tunnel survey was conducted to obtain precise horizontal and vertical alignment data. This survey was reconciled with the stitched MSI model and used to develop a tailored lay schedule for the liner pipe segments, using 0.61 m, 1.22 m, and 2.44 m lengths. The lay schedule was optimized to accommodate the geometric variability of the trunk while minimizing joint angular deflections and reducing the need for field laminations.

Groundwater infiltration management was critical to the project’s success. The downstream annular bulkhead was designed with integrated discharge ports and valves to control dewatering. Additional drainage holes were cored into the liner invert after bulkhead installation to facilitate passive drainage of the annular space prior to grouting. These features enabled safe, efficient grouting operations. They ensured the long-term performance of the liner.

Project Details

Project Owner: EPCOR Water Services

Engineer: Associated Engineering (Contractor’s Design-Build Engineer), SMA Consulting (Contractor’s Risk Engineer), and Stantec (Owner’s Engineer)

Contractor: Shanghai Construction Group (Canada) Corp.

Manufacturers/Suppliers: Hobas USA

Value of Trenchless Project (US$): $14,690,998

- How to Inspect and Assess Lateral Sewer Pipes

- Spotless Sewer Lines Play a Key Role in Lining Success

- How to Develop a Cost-Benefit Analysis for Pipeline Rehabilitation vs. Replacement

- How to Apply ASCE MOP 145 to Gravity Lining Projects

- How to Prepare and Trowel-Apply for a Manhole Rehab Project

Next Up

2026 Microtunneling Short Course | May 5-7, 2026 | Scottsdale, Arizona | Learn more