2025 Trenchless Technology Rehabilitation Project of the Year

North Outfall Sewer (NOS) Unit 10, Los Angeles

The North Outfall Sewer (NOS) Unit 10 rehabilitation project in the City of Los Angeles tackled numerous challenges to restore the 95-year-old structure, a vital element of the City’s complex sewer system.

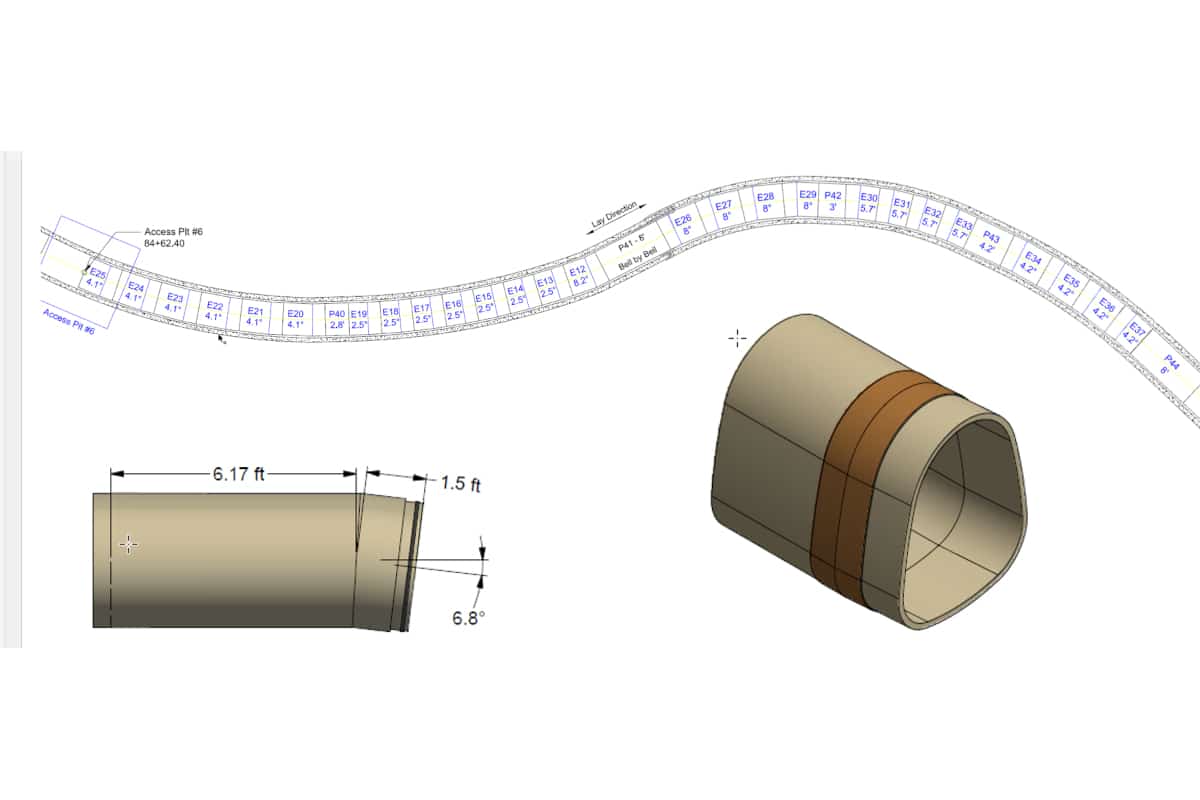

Unit 10 features semi-elliptical concrete sewer lined with tiles, comprising 1,426 ft of 48-in. pipe, 3,397 ft of 54-in. pipe and a unique 39-ft “squash box” segment crossing under a 108-in. storm drain. The alignment navigates five angle points and six curves, with more than 65 percent of the alignment passing beneath private property owned by Union Pacific Railroad and a popular winery.

Critical project hurdles included an array of innovative design considerations, worksite limitations, procurement of temporary construction easements, as well as sewer bypass strategies, railroad and county coordination and utility relocations, deep access pit excavations, custom pipe fabrication. Also, handling of public and private property concerns was paramount.

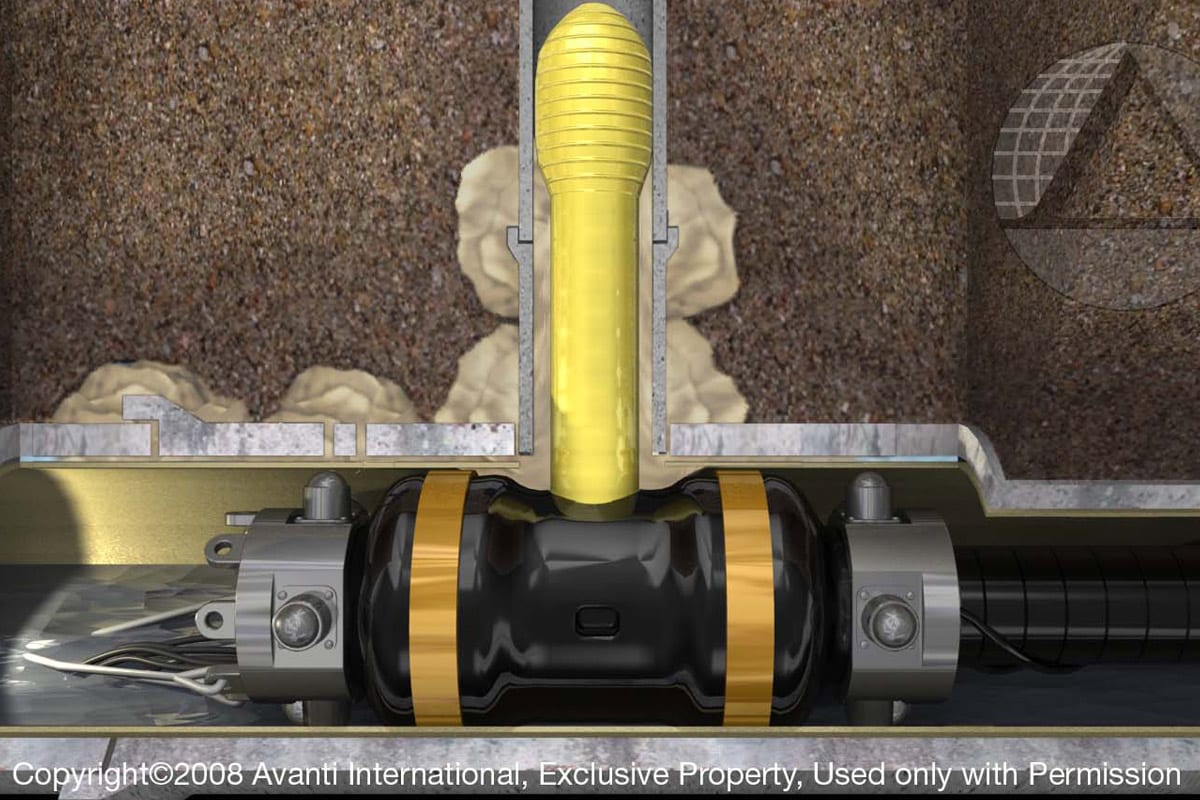

This project was successfully executed using sliplining as its rehab method, as well as fiberglass reinforced polymer mortar non-circular pipe. This pipe option from Hobas USA was selected for its strong resistance to corrosion, ease of installation and ability to conform to the non-circular geometry of the existing pipe.

For all these factors and more, The North Outfall Sewer Unit 10 is the 2025 Trenchless Technology Project of the Year for Rehabilitation.

“We were ecstatic that we were nominated and to win the award is just amazing,” says Spiniello Infrastructure West vice president of estimating and preconstruction Tony White, further acknowledging the work of Kent Meier, now director of operations at Spiniello Infrastructure West, who served as the project’s general superintendent. “Kent and his team developed creative solutions for the reconstruction of the squash box and the extensive sewer bypass system that handled more than 20 mgd at the railyard.”

“The [NOS] is definitely a main artery, so it is very important to the City,” says Ryan Toles, P.E., who was with the Bureau of Engineering/Department of Public Works for the City of Los Angeles during this project. “There is a whole program that the City has been taking on over the last many years to rehabilitate the entire NOS. So, many of these projects have been implemented. Some of the easier sections where it’s more straightforward, you’re already in the public right of way and access is not a challenge, have already been done.

“This is one of those projects that required a lot more planning and design in order to get it to the construction phase and actually finished,” he says. “That there is a rehab program for the entire NOS tells you how important it is to the City.

“Just the significant number of obstacles that this project had that could have derailed its success, being able to keep it on schedule and within budget are the things that come to mind about what makes this project a unique story and a success.”

Project Background

The North Outfall Sewer has been a critical component of Los Angeles’ sewer infrastructure since 1925. This sewer is one of the main trunk lines that brings sewage flow all the way from the valley to the Hyperion Water Reclamation Plant. Most of the outfall’s sections, also referred to as “units,” are approaching or are more than 100 years old.

Now in 2025, the NOS is found in an advanced state of deterioration with high levels of debris impacting hydraulic capacity and severe corrosion compromising structural integrity. Before work on Unit 10 began, an emergency repair was performed on adjacent Unit 9 in 2017 — an effort that would prove critical to the success of the Unit 10 project.

Los Angeles City Bureau of Engineering observed in some of the CCTV footage taken for the Unit 9 work that Unit 10 was compromised and identified a significant amount of corrosion.

“There was a lot of missing tile liners that were originally installed to protect the pipe from corrosion, and a lot of those tiles had fallen and were sitting at the bottom of the sewer and impacting capacity. They were no longer providing corrosion protection,” says Toles. “There was also a significant loss of pipe wall. The concrete had started to corrode with spots at various locations. Those were the triggers that initiated the Unit 10 project moving forward.”

Toles notes that the finding the deterioration allowed the City to proceed in a proactive manner vs. reactive, as it did for the Unit 9 project. The location of the Unit 10 project is in an area of Los Angeles called Taylor Junction, relatively close to downtown Los Angeles and runs parallel to the Los Angeles River. Toles says that there are several railroad companies and tracks along the alignment, including Union Pacific, Southern California Regional Railroad and L.A. County Metro Transit Agency, as well many businesses, including the San Antonio Winery.

“There was a lot of coordination with all of them during the design phase, as well as the other businesses in the area to make sure we minimize the impacts to them during construction as much as we could,” Toles says.

The City initially estimated the project cost at $52.5 million before putting it out to bid in 2021. In February 2022, Spiniello Infrastructure West was awarded the contract with a $33.5 million bid; work officially began following the notice to proceed in April 2022.

According to Toles, the substantial savings came from Spiniello’s innovative approach, especially in the design of the bypass system, construction of access pits strategically located near horizontal curves and between active heavy rails, and the “squash box” components.

Why Sliplining

The City evaluates its sewers on a scale of 1 to 5, with 1 indicating good condition and 5 signifying emergency failure, requiring immediate repair. Unit 10 received an average grade of 4, indicating it was in critical need of repair within two to five years of the assessment. The CCTV inspection results in 2018 showed that more than 35 percent of the wall surface experienced significant wall loss exceeding 1 in.

ity officials weren’t sure of which rehab method to employ but they knew they wanted to use trenchless technologies as much as possible. Sliplining and fiber reinforced polymer mortar noncircular (FRPM-NC) pipe checked off the critical boxes they sought for a structural rehabilitation of the pipe.

Gabriel Castelblanco is director of applications engineering-pressure at Hobas Pipe USA and says use of FRPM-NC was the best option for this particular project, citing its resistance to corrosion, as well as ability to create an increase in hydraulic capacity.

“The material is extremely strong,” he says. “To give you an idea, fiberglass tensile strength is higher than steel and the pipe composite properties are stronger than concrete.”

Before procuring sliplining and FRPM materials, the City used 3D sonar and laser profiling of the sewer. RedZone Robotics performed this work, producing key data on host pipe wall loss, deviations between the existing sewer profile and the original design, and other critical details. This information enabled the Hobas team to custom-fabricate 700 sections of pipe capable of navigating the alignment’s tight curves, including an S-curve beneath one of the railways. The data was also used to determine the quantity needed for the annulus grout, supplied by Cell-Crete.

Project Challenges

In addition to the complex design scope, the project presented multiple challenges for the owner, contractor, and engineers. From a logistical standpoint, securing the necessary permits and approvals from local, state, and federal agencies proved demanding — particularly when coordinating with multiple railroad companies, each with its own set of requirements.

Construction also required deep access pits within active rail yards. Spiniello positioned one pit between heavy rail lines, with active tracks less than 15 ft from its edge, and extended another more than 50 ft deep, necessitating a specially engineered shoring system. Within this pit, the existing NOS crossed beneath a 108-in. storm drain through the previously mentioned squash box. Spiniello removed both the squash box and the storm drain and reconstructed during the dry season. The squash box was constructed using FRPM NC pipes.

The tight work space, coupled with working adjacent to the active rail and multiple train schedules and being compliance with Southern California Regional Rail Authority regulations required creative solutions by Spiniello to push through. To ensure uninterrupted service, a bypass system was installed the contractor to handle continuous flows.

Spiniello installed bypass equipment at multiple points along the 5,000-ft alignment to maintain flow, which reached up to 20 mgd during rain events. Since upstream flow diversion was not possible, a series of sewer bypass systems were constructed to enable cleaning and sliplining operations. The primary bypass extended more than two miles and used six 12-in. Xylem pumps to reroute the main sewer flows, while a secondary bypass was built to accommodate a 24-in. sideline.

Castelblanco notes that most of the pre-planning and design work occurred during the COVID pandemic years of 2020 and 2021, at a time when supply chain and pricing of raw materials were at issue. The negotiated cost of resin, for example, for the pipe became extremely important, he says.

Coordination and Communication

All parties emphasized the exceptional commitment to communication throughout every phase of the project. From permitting and design adjustments to site logistics, the team ensured that plans were clearly conveyed, and potential issues were addressed without being overlooked. Issues arise? A conflict program was in place.

“We have what’s called an issue resolution ladder and it has four levels on it,” Toles explains. “Most issues start at level one and if eventually things don’t get resolved, it can escalate up to level four. I would say 95 percent of the issues were resolved at level one.”

Regular third-party–facilitated partnering meetings were also held throughout the project, helping to surface unresolved issues early and establish a path forward before they became critical.

An example of the communication and coordination efforts was the handling of the incredible amount of pipe needed for the project.

“We worked with [the Spiniello team] closely on the section of pipes they were installing as it was complicated,” Castelblanco says, as an example. “We had to have sections that were going to fit like a puzzle inside the sewer. We had to coordinate with them very closely on what section they were working on, how they are going to be carrying those into the pipe and have the correct pieces at the correct time.”

While countless individuals contributed to the project’s success, Toles highlights two in particular for their work and leadership: Edward Arrington, who led the division responsible for the project’s design, and Bing Neris, the City’s lead construction manager in the field.

“We’re very proud of this project, which was an amazing and complicated project,” Castelblanco says. “The amazing success that project had was unbelievable because so many things could have gone in the wrong direction but thanks to the great partnerships, communication and great ideas, we were successful.”

Project Details

Project Owner: City of Los Angeles

Engineer: City of Los Angeles, Bureau of Engineering

Contractor: Spiniello Infrastructure West, National Plant

Manufacturers/Suppliers: Hobas USA, Xylem, RedZone Robotics, Cell Crete

Value of Trenchless Project (US$): $33.5 million

Sharon M. Bueno is editor of Trenchless Technology.

- How to Inspect and Assess Lateral Sewer Pipes

- Spotless Sewer Lines Play a Key Role in Lining Success

- How to Develop a Cost-Benefit Analysis for Pipeline Rehabilitation vs. Replacement

- How to Apply ASCE MOP 145 to Gravity Lining Projects

- How to Prepare and Trowel-Apply for a Manhole Rehab Project

Next Up

2026 Microtunneling Short Course | May 5-7, 2026 | Scottsdale, Arizona | Learn more